Hey there! I'm a supplier of auto door CMM holding jigs. You might think these jigs are all sunshine and rainbows, but like any tool or product, they come with their fair share of disadvantages. Let's dive into what those might be.

High Initial Investment

First off, the cost of getting an auto door CMM holding jig can be a real pain in the wallet. These things aren't cheap. You've got to shell out a significant amount of money upfront to purchase one. And it's not just the cost of the jig itself. You also need to factor in the cost of installation, calibration, and any training that your staff might need to use it properly.

For small and medium - sized businesses, this can be a huge barrier. They might not have the financial resources to make such a big investment, especially when they're just starting out or trying to manage their cash flow. Even for larger companies, it's still a major expense. And if you're not careful, you could end up over - investing in a jig that doesn't quite meet your needs.

Maintenance and Repair Costs

Once you've got your auto door CMM holding jig up and running, the costs don't stop there. Maintenance is an ongoing expense. These jigs are complex pieces of equipment, and they need regular upkeep to ensure they're working correctly. You've got to clean them, lubricate the moving parts, and check for any signs of wear and tear.

And when something goes wrong, the repair costs can be astronomical. You might need to call in a specialist technician, who will charge you a hefty fee for their time and expertise. Plus, you've got to factor in the cost of replacement parts, which can also be quite expensive. If your jig breaks down during a critical production period, it can cause major delays and lost revenue.

Limited Flexibility

Auto door CMM holding jigs are designed to hold specific types of auto doors. This means they're not very flexible. If you want to use them for different door models or sizes, you might run into problems. You might need to purchase additional jigs or make significant modifications to the existing one.

This lack of flexibility can be a real headache for manufacturers. They might have to deal with multiple jigs for different products, which takes up more space in the factory and adds to the overall cost. It also makes it harder to adapt to changes in the market or customer demands. For example, if a new type of auto door becomes popular, you might not be able to use your existing jig to measure it accurately.

Training Requirements

Using an auto door CMM holding jig isn't as simple as just plugging it in and turning it on. Your staff needs to be properly trained to use it effectively. This training can take a long time and can be quite expensive. You've got to pay for the training materials, the instructor's time, and the time that your employees are away from their regular work.

And even after the training, there's no guarantee that your staff will be able to use the jig correctly all the time. They might make mistakes, which can lead to inaccurate measurements and defective products. This can damage your reputation and cost you money in terms of returns and customer complaints.

Dependency on Technology

These days, auto door CMM holding jigs are highly technological. They rely on sensors, software, and other advanced components to function properly. While this technology can provide accurate measurements, it also means that you're highly dependent on it.

If there's a software glitch or a problem with the sensors, your jig might stop working. And since these jigs are so complex, it can be difficult to diagnose and fix the problem quickly. You might have to wait for the manufacturer to release a software update or send a technician to your facility. This can cause significant downtime and disrupt your production schedule.

Compatibility Issues

Auto door CMM holding jigs need to be compatible with your existing manufacturing equipment and software. If there are compatibility issues, it can cause all sorts of problems. For example, the jig might not be able to communicate properly with your quality control software, which can lead to inaccurate data being recorded.

You might also run into issues with the physical connection between the jig and your other equipment. If the jig doesn't fit properly or if the interfaces don't match, it can be difficult to integrate it into your production line. This can slow down your production process and increase the risk of errors.

Obsolescence Risk

Technology is advancing at a rapid pace, and auto door CMM holding jigs are no exception. What might be state - of - the - art today could be obsolete in a few years. If you invest in a jig that becomes obsolete, you'll be stuck with a piece of equipment that's no longer useful.

You'll have to either upgrade the jig, which can be expensive, or purchase a new one. And if you're constantly having to upgrade or replace your jigs, it can add up to a significant cost over time. This is a risk that all manufacturers need to consider when making an investment in an auto door CMM holding jig.

Despite all these disadvantages, auto door CMM holding jigs can still be a valuable tool for many manufacturers. They can provide accurate measurements, improve quality control, and increase efficiency. If you're considering purchasing one, it's important to weigh the pros and cons carefully.

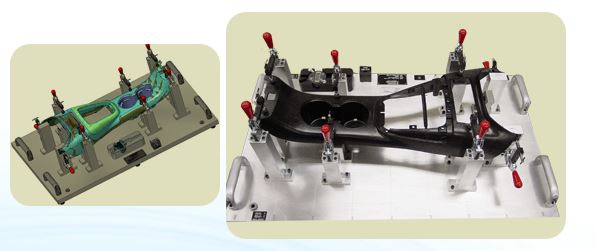

If you're interested in learning more about our Console Trim Bezels CMM Holding Fixture, Gauges For Automotive Door Parts Manufacturer, or Door Parts CMM Holding Fixture, feel free to reach out. We're here to help you make the right decision for your business. Whether you want to discuss the disadvantages further or explore how our products can work for you, we're just a message away. Let's start a conversation and see if we can find the best solution for your auto door measurement needs.

References

- Industry reports on automotive manufacturing equipment costs

- Interviews with manufacturers using auto door CMM holding jigs

- Technical specifications of auto door CMM holding jigs from various suppliers