Hey there! As a supplier of rear seats welding jigs, I've been in the game for quite a while, and I've heard all sorts of customer reviews. In this blog, I'm gonna share some of the feedback we've gotten on different types of rear seats welding jigs and what it means for your business.

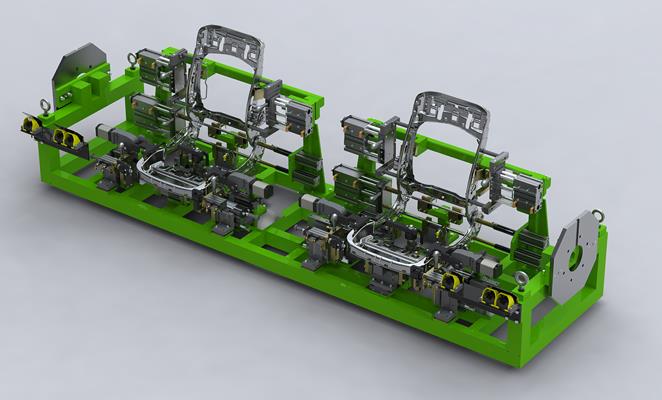

First off, let's talk about the importance of a good rear seats welding jig. When you're manufacturing car seats, precision is key. A welding jig helps ensure that all the parts are properly aligned and welded together, which not only improves the quality of the final product but also boosts efficiency. If the jig isn't up to par, you could end up with seats that don't fit right, have weak welds, or take longer to produce. And that's a big no - no in the automotive industry.

One type of rear seats welding jig we offer is the adjustable one. Customers who've used our adjustable jigs have been pretty stoked about them. One auto parts manufacturer said that the ability to adjust the jig according to different seat designs was a game - changer. They could switch between different models of rear seats without having to invest in a whole new set of jigs. This saved them a ton of money in the long run. Another customer mentioned that the adjustment process was relatively easy. They didn't have to spend hours training their staff to use the jig, which meant they could get back to production quickly.

On the flip side, some customers did have a few complaints about the adjustable jigs. A small - scale workshop reported that the adjustable parts sometimes got a bit loose after a while of use. This led to some minor misalignments in the welding process. But we've been working on this issue, and we've made some improvements to the locking mechanisms to make sure that the adjustable parts stay in place.

Then there are the custom - made rear seats welding jigs. These are designed specifically for a particular customer's needs. We've had some really positive feedback on these. A large automotive company that ordered a custom jig for their high - end luxury car seats was extremely satisfied. They said that the jig was perfectly tailored to their seat design, which resulted in a much higher quality weld. The welds were stronger and more consistent, which improved the overall durability of the seats. They also mentioned that the custom jig fit seamlessly into their existing production line, which made the manufacturing process smoother.

However, custom - made jigs do come with their own set of challenges. One customer who ordered a custom jig for a new and innovative seat design found that the lead time was a bit longer than they expected. Since the jig had to be designed from scratch, it took some time to finalize the design and then manufacture it. But we always try to communicate clearly with our customers about the lead time so that they can plan their production schedules accordingly.

Now, let's take a look at how our rear seats welding jigs compare to some other types of welding fixtures in the automotive industry. For example, Car Stamping Parts checking fixture is used for checking the accuracy of car stamping parts. While it's a different type of fixture, the principle of precision is the same. Our rear seats welding jigs focus on ensuring precise welding of seat components, just like the checking fixture focuses on the accuracy of stamping parts.

Another related product is the Automotive Seat Welding Fixture. Our rear seats welding jigs are a part of this broader category. But what sets our jigs apart is our focus on customization and adjustability. We understand that different customers have different needs, and we strive to meet those needs with our products.

And let's not forget about the Front Bumper Welding Fixture. Just like our rear seats welding jigs, the front bumper welding fixture is crucial for ensuring a high - quality weld. But each type of fixture has its own unique requirements. For rear seats, the focus is on ergonomics and comfort as well as structural integrity, while for front bumpers, it's more about impact resistance and aerodynamics.

In conclusion, customer reviews of our rear seats welding jigs have been mostly positive, but there's always room for improvement. We're constantly listening to our customers' feedback and working on making our products even better. Whether you're a small workshop looking for an adjustable jig or a large automotive company in need of a custom - made solution, we've got you covered.

If you're in the market for rear seats welding jigs, I encourage you to reach out to us. We can have a chat about your specific requirements and see how we can help you improve your production process. Don't hesitate to get in touch and start a conversation about your next project.

References

- Customer feedback from various automotive parts manufacturers and workshops.

- Industry knowledge and experience in the automotive welding fixture sector.