As a leading supplier of auto door CMM (Coordinate Measuring Machine) holding jigs, I am often asked about the ergonomic features of these essential tools. In this blog post, I will delve into the key ergonomic aspects of an auto door CMM holding jig, explaining how they contribute to improved efficiency, accuracy, and operator comfort.

1. Adjustable Design

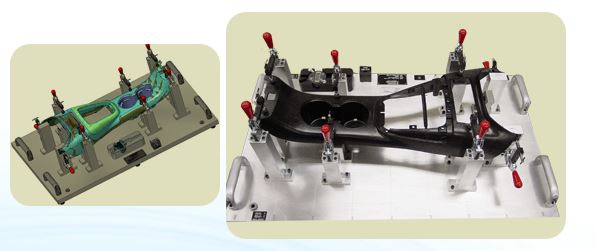

One of the most significant ergonomic features of an auto door CMM holding jig is its adjustable design. Auto doors come in various shapes, sizes, and configurations, and a one - size - fits - all approach is not practical. Our holding jigs are equipped with adjustable components that can be customized to accommodate different door models.

For example, the height of the holding arms can be adjusted to match the vertical position of the door. This is crucial because it allows the operator to position the door at a comfortable working height, reducing the need for excessive bending or reaching. By minimizing awkward postures, we can prevent musculoskeletal disorders (MSDs) that are common among workers who perform repetitive tasks.

The angle of the holding arms can also be adjusted. This feature is particularly useful when measuring doors with complex geometries. Operators can set the holding arms at the optimal angle to ensure that the door is held securely and that the CMM can access all the necessary measurement points without interference. This not only improves the accuracy of the measurements but also makes the measurement process more efficient.

2. Lightweight Materials

We understand that operators need to handle the auto door CMM holding jigs regularly. Therefore, we use lightweight yet durable materials in the construction of our jigs. Materials such as high - strength plastics and aluminum alloys are commonly used.

The use of lightweight materials reduces the physical strain on the operators. When they need to move the holding jig to different workstations or adjust its position, they can do so with minimal effort. This is especially important in a production environment where time is of the essence, and operators need to be able to work quickly and efficiently.

Moreover, lightweight materials do not compromise the structural integrity of the holding jig. Our jigs are designed to withstand the forces exerted during the measurement process, ensuring that they can hold the auto doors securely and accurately.

3. User - Friendly Controls

The controls of our auto door CMM holding jigs are designed with the user in mind. They are intuitive and easy to operate, even for novice users.

The adjustment knobs and levers are large and well - marked, making it easy for operators to identify and use them. The controls are also placed within easy reach of the operator, reducing the need for excessive stretching or twisting.

In addition, some of our advanced holding jigs are equipped with digital controls. These controls allow operators to make precise adjustments to the position and angle of the holding arms with the push of a button. This not only improves the accuracy of the adjustments but also speeds up the setup process.

4. Anti - Slip Surfaces

Safety is a top priority in any manufacturing environment. Our auto door CMM holding jigs are designed with anti - slip surfaces to prevent accidents.

The contact points between the holding arms and the auto door are coated with a non - slip material. This ensures that the door is held firmly in place during the measurement process, reducing the risk of the door slipping or falling.

The handles of the holding jig are also designed with anti - slip grips. This provides a secure hold for the operators, even when their hands are wet or greasy. By reducing the risk of slips and falls, we can create a safer working environment for our customers' employees.

5. Modular Design

Our auto door CMM holding jigs feature a modular design. This means that different components of the jig can be easily replaced or upgraded.

For example, if a particular holding arm is damaged, it can be quickly removed and replaced with a new one. This reduces downtime and maintenance costs.

The modular design also allows for easy customization. Customers can add or remove components based on their specific measurement requirements. This flexibility ensures that our holding jigs can adapt to changing production needs, providing long - term value for our customers.

6. Compatibility with CMM Systems

Our auto door CMM holding jigs are designed to be fully compatible with a wide range of CMM systems. This compatibility is essential for seamless integration into the existing measurement processes of our customers.

The jigs are designed to provide a stable and accurate platform for the CMM probes. They ensure that the probes can access all the necessary measurement points on the auto door without any interference. This improves the accuracy and reliability of the measurement results.

In addition, our jigs are equipped with features that allow for easy alignment with the CMM system. This reduces the setup time and ensures that the measurement process can start quickly.

7. Noise Reduction Features

In a manufacturing environment, noise can be a significant source of stress for operators. Our auto door CMM holding jigs are designed with noise reduction features.

The moving parts of the jig are lubricated to reduce friction and noise. This creates a quieter working environment, which is more comfortable for the operators.

In addition, the materials used in the construction of the jig are selected for their sound - dampening properties. This further reduces the noise generated during the operation of the holding jig.

Conclusion

The ergonomic features of our auto door CMM holding jigs are designed to improve the efficiency, accuracy, and comfort of the measurement process. By providing adjustable designs, lightweight materials, user - friendly controls, anti - slip surfaces, modular designs, compatibility with CMM systems, and noise reduction features, we can help our customers create a safer and more productive working environment.

If you are in the market for high - quality auto door CMM holding jigs, we invite you to explore our product range. You can find more information about our Console Trim Bezels CMM Holding Fixture, Auto Door CMM Holding Fixture, and Door Parts CMM Holding Fixture on our website. We are always ready to discuss your specific requirements and provide you with the best solutions for your measurement needs. Contact us today to start the procurement and negotiation process.

References

- Konz, S., & Johnson, S. (2000). Work Design: Industrial Ergonomics. Holcomb Hathaway.

- Grandjean, E. (2001). Fitting the Task to the Man: An Introduction to Occupational Ergonomics. Taylor & Francis.