Hey there! I'm a supplier of rear seats welding jigs, and I've been thinking a lot about the opportunities for innovation in this field. In this blog, I'll share my thoughts on where we can push the boundaries and make some real improvements.

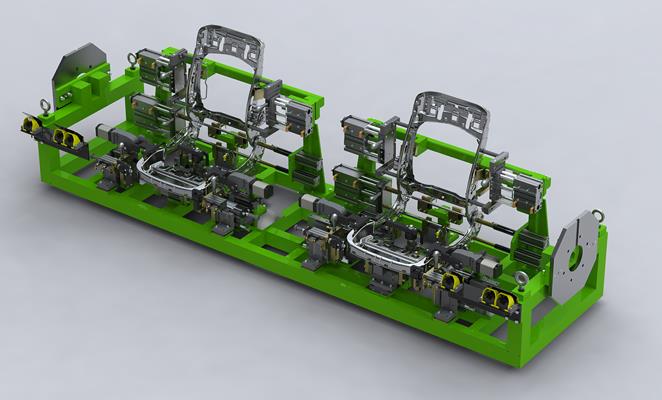

First off, let's talk about what rear seats welding jigs are and why they're important. These jigs are used in the automotive industry to hold the rear seat components in place during the welding process. They ensure that the parts are aligned correctly, which is crucial for the structural integrity and safety of the vehicle. A well-designed welding jig can also improve the efficiency of the welding process, reducing production time and costs.

So, where are the opportunities for innovation? One area that comes to mind is automation. With the advancements in robotics and artificial intelligence, there's a huge potential to automate the welding process using rear seats welding jigs. Automated jigs can be programmed to perform precise movements, ensuring consistent weld quality and reducing the risk of human error. They can also work around the clock, increasing production capacity. For example, we could develop jigs that use sensors to detect the position of the seat components and adjust themselves accordingly. This would eliminate the need for manual adjustments and speed up the setup process.

Another opportunity lies in the use of new materials. Traditional welding jigs are often made of steel, which is heavy and can be expensive to manufacture. By exploring alternative materials such as lightweight alloys or composites, we could reduce the weight of the jigs without sacrificing strength. This would not only make the jigs easier to handle but also reduce the energy consumption during the manufacturing process. Additionally, some new materials may have better corrosion resistance, which would extend the lifespan of the jigs.

Customization is also a big trend in the automotive industry, and rear seats welding jigs are no exception. Different car models have different seat designs, and manufacturers are constantly looking for ways to differentiate their products. As a supplier, we can offer customized jigs that are tailored to the specific requirements of each customer. This could involve designing jigs with adjustable features or creating unique fixtures for special seat configurations. By providing customized solutions, we can help our customers stay competitive in the market.

In terms of technology integration, we can look into incorporating smart features into our rear seats welding jigs. For instance, we could add IoT (Internet of Things) capabilities to the jigs. This would allow us to monitor the performance of the jigs in real-time, track their usage, and even predict maintenance needs. We could also use data analytics to optimize the welding process based on the collected data. For example, if we notice that a particular jig is experiencing more wear and tear in a certain area, we can adjust the welding parameters or schedule maintenance earlier.

Now, let's take a look at some related products that might be of interest. If you're also involved in the automotive manufacturing process, you might want to check out our Car Stamping Parts checking fixture. This fixture is used to ensure the accuracy of car stamping parts, which is essential for a seamless assembly process. Another product is our Automotive Seat Welding Fixture, which is specifically designed for welding various parts of the automotive seat. And if you're working on the front bumper, our Front Bumper Welding Fixture can provide the necessary support and precision during the welding process.

As a rear seats welding jig supplier, I'm excited about the future of this industry. The opportunities for innovation are endless, and I believe that by embracing new technologies and materials, we can create products that are more efficient, reliable, and cost-effective. If you're in the market for rear seats welding jigs or any of our related products, I encourage you to reach out to us. We'd love to have a chat about your specific needs and see how we can help you take your automotive manufacturing process to the next level.

References

- Industry reports on automotive manufacturing trends

- Research papers on materials science and automation in manufacturing