As a supplier of auto door CMM holding jigs, I often encounter various inquiries from customers, and one question that comes up quite frequently is whether an auto door CMM holding jig can be used in wet environments. In this blog post, I'll delve into this topic, exploring the factors at play, potential challenges, and possible solutions.

Understanding Auto Door CMM Holding Jigs

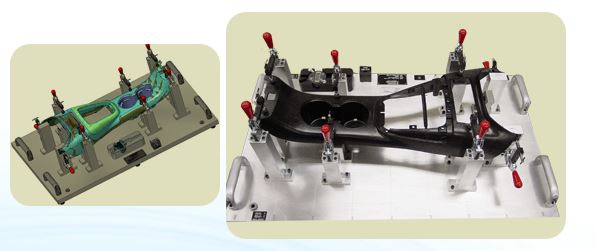

Before we discuss the suitability of using auto door CMM holding jigs in wet environments, let's first understand what these jigs are and their functions. An auto door CMM (Coordinate Measuring Machine) holding jig is a specialized tool designed to hold automotive door parts securely during the measurement process using a CMM. The precise positioning and stability provided by these jigs are crucial for obtaining accurate measurements, which are essential for ensuring the quality and fit of automotive door components.

Auto door CMM holding jigs are typically made from high - quality materials such as aluminum, steel, or plastic, depending on the specific requirements of the application. They are engineered to be durable, precise, and resistant to wear and tear. For more information on our Auto Door CMM Holding Fixture, you can visit our website.

Factors Affecting the Use of Auto Door CMM Holding Jigs in Wet Environments

Material Compatibility

The first and most significant factor to consider is the material of the holding jig. Different materials react differently to moisture. For example, steel is prone to rusting when exposed to water and oxygen. Rust can not only damage the surface of the jig but also affect its dimensional accuracy over time. Aluminum, on the other hand, forms a protective oxide layer when exposed to air, which can provide some resistance to corrosion. However, in highly corrosive wet environments, even aluminum may require additional protection.

Plastic materials can be a good choice for wet environments as they are generally resistant to water and corrosion. But they may have limitations in terms of strength and stiffness compared to metal materials. Our Gauges For Automotive Door Parts Manufacturer section provides details on different materials used in our products.

Precision and Accuracy

Wet environments can pose a threat to the precision and accuracy of auto door CMM holding jigs. Moisture can cause expansion or contraction of the jig material, leading to dimensional changes. Even small changes in dimensions can result in inaccurate measurements, which can have a significant impact on the quality control of automotive door parts. Additionally, water droplets on the surface of the jig can interfere with the measurement sensors of the CMM, causing errors in the measurement results.

Contamination

In wet environments, there is also a risk of contamination. Water can carry dirt, debris, and chemicals, which can accumulate on the surface of the holding jig. This contamination can not only affect the accuracy of the measurements but also cause damage to the jig over time. For example, abrasive particles in the water can scratch the surface of the jig, reducing its lifespan.

Challenges of Using Auto Door CMM Holding Jigs in Wet Environments

Corrosion and Degradation

As mentioned earlier, corrosion is a major challenge in wet environments. Corrosion can weaken the structure of the holding jig, leading to potential failure during use. It can also cause pitting and roughness on the surface of the jig, which can affect the fit and positioning of the automotive door parts. Over time, the degradation of the jig due to corrosion can result in increased maintenance costs and reduced productivity.

Maintenance Requirements

Using auto door CMM holding jigs in wet environments requires more frequent and thorough maintenance. The jigs need to be cleaned regularly to remove dirt, debris, and any corrosive substances. Special coatings or treatments may also need to be applied periodically to protect the surface of the jig. This increased maintenance can be time - consuming and costly for manufacturers.

Impact on Measurement Accuracy

The presence of moisture can directly impact the measurement accuracy of the CMM. Water can cause electrical interference in the measurement sensors, leading to false readings. Moreover, the dimensional changes caused by moisture can make it difficult to obtain consistent and reliable measurement results. This can be a major concern for automotive manufacturers, as accurate measurements are crucial for ensuring the quality and safety of their products.

Possible Solutions

Material Selection

Choosing the right material is the first step in ensuring the suitability of auto door CMM holding jigs for wet environments. As discussed, plastic materials can be a good option due to their corrosion resistance. If metal materials are preferred, stainless steel can be used instead of regular steel, as it has better corrosion resistance. Additionally, some advanced composite materials may offer a combination of strength, durability, and corrosion resistance.

Surface Treatment

Applying a protective surface treatment to the holding jig can significantly enhance its resistance to corrosion. For example, powder coating, anodizing, or plating can create a barrier between the jig material and the wet environment. These treatments can also improve the wear resistance of the jig, extending its lifespan.

Sealing and Enclosure

Using seals and enclosures can help protect the auto door CMM holding jigs from direct contact with water. Seals can prevent water from entering the critical areas of the jig, while enclosures can provide an additional layer of protection. This can reduce the risk of corrosion and contamination, as well as protect the measurement sensors from moisture.

Regular Inspection and Maintenance

Establishing a regular inspection and maintenance schedule is essential for using auto door CMM holding jigs in wet environments. The jigs should be inspected for signs of corrosion, wear, and damage on a regular basis. Any issues should be addressed promptly to prevent further deterioration. Regular cleaning and lubrication can also help maintain the performance of the jigs.

Case Studies

In some automotive manufacturing plants where the production process involves wet operations, such as painting or washing, auto door CMM holding jigs have been successfully used with proper precautions. For example, a plant that uses plastic auto door CMM holding jigs with a protective coating has reported minimal corrosion and maintenance issues. By implementing a strict cleaning and inspection schedule, they have been able to maintain the accuracy of their measurements and ensure the quality of their automotive door parts.

Another plant that uses stainless - steel holding jigs with enclosures has also achieved good results. The enclosures protect the jigs from direct water exposure, and the stainless - steel material provides sufficient strength and corrosion resistance. This has allowed them to continue using the jigs in a wet environment without significant degradation.

Conclusion

In conclusion, while using auto door CMM holding jigs in wet environments presents several challenges, it is possible with the right approach. By carefully selecting materials, applying appropriate surface treatments, using seals and enclosures, and implementing a regular maintenance schedule, manufacturers can overcome these challenges and use the jigs effectively in wet environments.

If you are an automotive manufacturer looking for high - quality auto door CMM holding jigs that can be used in various environments, including wet ones, we are here to help. Our Console Trim Bezels CMM Holding Fixture and other products are designed to meet the highest standards of precision and durability. Contact us to discuss your specific requirements and explore how our products can benefit your manufacturing process.

References

- "Materials Science and Engineering: An Introduction" by William D. Callister Jr. and David G. Rethwisch

- "Automotive Manufacturing Technology" by John A. Schey