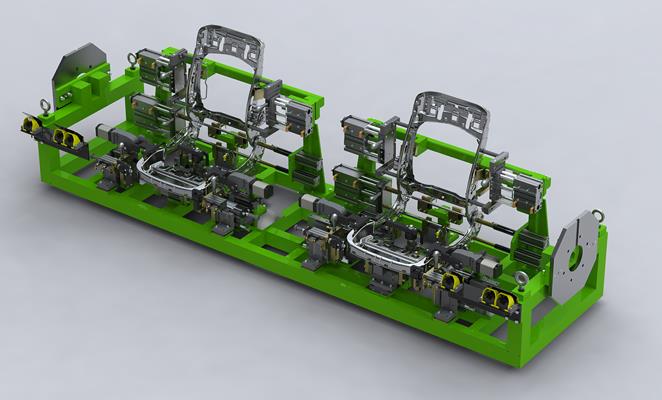

In the automotive manufacturing industry, precision and efficiency are of utmost importance. One crucial tool that significantly contributes to achieving these goals is the rear seats welding jig. As a reputable rear seats welding jig supplier, I've witnessed firsthand the transformative impact these jigs have on the production process. In this blog post, I'll delve into the numerous advantages of using a rear seats welding jig, highlighting why it's an indispensable asset for automotive manufacturers.

Enhanced Precision and Quality

One of the primary advantages of using a rear seats welding jig is the ability to achieve unparalleled precision in the welding process. Welding jigs are designed to hold the components of the rear seats in a fixed position, ensuring that each part is accurately aligned before the welding begins. This precise alignment is crucial for creating strong, durable welds that meet the strict quality standards of the automotive industry.

By using a welding jig, manufacturers can minimize the risk of misalignment, which can lead to weak welds, structural defects, and even safety issues. The jig's design allows for consistent and repeatable positioning of the components, resulting in uniform welds across all rear seats produced. This not only improves the overall quality of the finished product but also reduces the likelihood of rework and scrap, saving time and money in the long run.

Increased Efficiency and Productivity

In addition to enhancing precision, rear seats welding jigs also significantly improve efficiency and productivity in the manufacturing process. By holding the components in place, the jig eliminates the need for manual positioning and alignment, which can be time-consuming and prone to error. This allows welders to focus on the actual welding process, increasing the speed and accuracy of their work.

Furthermore, welding jigs can be designed to accommodate multiple components simultaneously, allowing for batch welding. This means that several rear seats can be welded at the same time, reducing the overall production time and increasing the output of the manufacturing line. With the ability to produce more rear seats in less time, manufacturers can meet the growing demand for their products and improve their competitiveness in the market.

Improved Worker Safety

Worker safety is a top priority in any manufacturing environment, and rear seats welding jigs play a crucial role in ensuring a safe workplace. By holding the components in place, the jig reduces the need for workers to manually handle hot and heavy parts during the welding process, minimizing the risk of burns, cuts, and other injuries.

In addition, welding jigs can be equipped with safety features such as guards and shields to protect workers from sparks, fumes, and other hazards associated with welding. These features not only help to prevent accidents but also improve the overall working conditions for welders, leading to increased job satisfaction and productivity.

Cost Savings

Using a rear seats welding jig can also result in significant cost savings for automotive manufacturers. As mentioned earlier, the jig's ability to improve precision and efficiency reduces the likelihood of rework and scrap, saving money on materials and labor. In addition, the increased productivity and output of the manufacturing line can lead to economies of scale, allowing manufacturers to produce rear seats at a lower cost per unit.

Furthermore, welding jigs are a long-term investment that can provide years of reliable service. Once the initial investment is made, the jig can be used repeatedly, reducing the need for frequent tooling changes and replacements. This not only saves money but also minimizes downtime and disruption to the manufacturing process.

Versatility and Customization

Another advantage of rear seats welding jigs is their versatility and customization options. Welding jigs can be designed to accommodate a wide range of rear seat designs and configurations, making them suitable for use in various automotive applications. Whether you're manufacturing rear seats for a compact car, a luxury sedan, or an SUV, a welding jig can be tailored to meet your specific requirements.

In addition, welding jigs can be easily modified and updated to accommodate changes in the design or specifications of the rear seats. This flexibility allows manufacturers to adapt to market trends and customer demands quickly, without having to invest in new tooling or equipment.

Compatibility with Other Manufacturing Processes

Rear seats welding jigs are also compatible with other manufacturing processes, such as assembly and inspection. Once the rear seats are welded using the jig, they can be easily transferred to the assembly line for further processing, such as the installation of upholstery and other components. This seamless integration between the welding and assembly processes improves the overall efficiency of the manufacturing line and reduces the time and cost associated with transferring parts between different workstations.

In addition, welding jigs can be designed to facilitate inspection and quality control. By holding the components in a fixed position, the jig allows for easy access to the welds, making it easier for inspectors to check for defects and ensure that the rear seats meet the required quality standards. This helps to identify and address any issues early in the manufacturing process, reducing the likelihood of defective products reaching the market.

Conclusion

In conclusion, the advantages of using a rear seats welding jig are numerous and significant. From enhanced precision and quality to increased efficiency and productivity, improved worker safety, cost savings, versatility, and compatibility with other manufacturing processes, welding jigs are an essential tool for automotive manufacturers. As a rear seats welding jig supplier, I'm committed to providing high-quality jigs that meet the specific needs and requirements of my customers.

If you're an automotive manufacturer looking to improve the quality, efficiency, and productivity of your rear seat manufacturing process, I encourage you to consider using a rear seats welding jig. Contact me today to learn more about our products and how they can benefit your business. Let's work together to take your rear seat manufacturing to the next level.

References

- Industry standards and best practices in automotive welding.

- Case studies and success stories from automotive manufacturers using rear seats welding jigs.

- Technical specifications and design considerations for rear seats welding jigs.