As a supplier of rear seats welding jigs, ensuring the authenticity and quality of industry certifications is crucial. Industry certifications not only serve as a mark of quality and compliance but also build trust with customers. In this blog post, I'll share some practical steps on how to verify the industry certifications of a rear seats welding jig.

Understand the Importance of Industry Certifications

Before delving into the verification process, it's essential to understand why industry certifications matter. Certifications such as ISO 9001 for quality management systems, ISO 14001 for environmental management, and relevant automotive industry - specific certifications like IATF 16949 demonstrate that the rear seats welding jig meets certain standards of quality, safety, and environmental responsibility. These certifications can influence a customer's purchasing decision, as they provide assurance that the product is reliable and compliant with industry - wide best practices.

Request Certification Documents

The first step in verifying industry certifications is to request the official certification documents from the supplier. A legitimate supplier should be able to provide clear, up - to - date copies of their certifications. These documents typically include the name of the certifying body, the certification number, the scope of the certification (which should cover rear seats welding jigs), and the validity period.

When examining these documents, pay close attention to the details. Check if the certification is relevant to the manufacturing of rear seats welding jigs. For example, if the certification is for general metal fabrication but does not specifically mention welding jigs for automotive rear seats, it may not be as relevant. Also, verify the expiration date of the certification. An expired certification is no longer valid, and it could indicate that the supplier has not maintained the required standards.

Contact the Certifying Body

Once you have the certification documents, you can directly contact the certifying body to confirm their authenticity. Most certifying bodies have online verification tools on their official websites. You can enter the certification number and other relevant details to check if the certification is valid.

If the online verification tool is not available or you have further questions, you can reach out to the certifying body via email or phone. Provide them with the supplier's name, the certification number, and the scope of the certification. The certifying body will be able to confirm whether the certification is genuine and if it is still in effect. This direct verification method is one of the most reliable ways to ensure that the supplier's claims about their certifications are true.

Check for Third - Party Audits

Many industry certifications require regular third - party audits to maintain their validity. These audits are conducted by independent organizations to assess the supplier's compliance with the certification standards. You can ask the supplier about their audit history. A reputable supplier should be able to provide details about the most recent audits, including the audit results and any corrective actions taken.

You can also try to obtain information about the auditing firm. Reputable auditing firms are well - known in the industry and have a track record of conducting thorough and objective audits. If possible, contact the auditing firm to confirm that they have indeed conducted an audit on the supplier and to get more information about the audit process and results.

Look for Industry Reputation and References

In addition to verifying the certifications themselves, it's important to consider the supplier's overall industry reputation. Look for customer reviews and testimonials. You can search online for feedback from other companies that have purchased rear seats welding jigs from the supplier. Positive reviews can be a good indication that the supplier is reliable and that their certifications are likely to be genuine.

You can also ask the supplier for references. A legitimate supplier should be willing to provide contact information for some of their previous customers. Reach out to these references and ask about their experience with the supplier. Inquire about the quality of the welding jigs, the compliance with industry standards, and whether the certifications seemed to be valid.

Compare with Industry Standards

Familiarize yourself with the industry standards associated with rear seats welding jigs. For example, standards related to dimensional accuracy, material quality, and welding strength. You can then compare the supplier's claims about their products and certifications with these standards.

If the supplier claims that their rear seats welding jigs meet a certain level of precision but the certification details do not clearly support this, it could be a red flag. You can also use industry associations and trade publications to stay informed about the latest standards and best practices. This knowledge will help you better evaluate the supplier's certifications and the quality of their products.

Consider the Supplier's Manufacturing Process

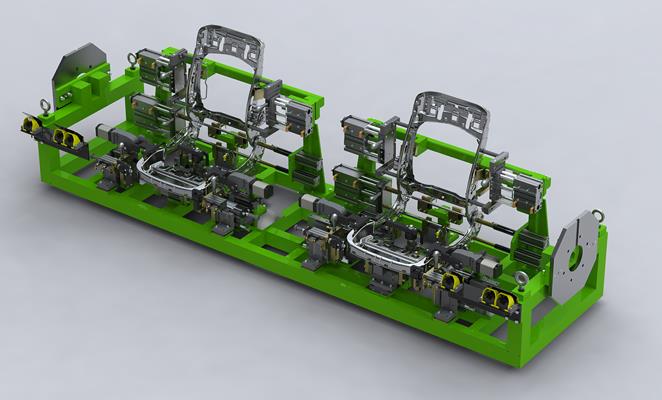

Understanding the supplier's manufacturing process can also give you insights into the validity of their certifications. A certified supplier should have a well - documented and controlled manufacturing process. They should be able to explain how they ensure quality at each stage of production, from material sourcing to final assembly.

For example, if the certification requires strict control of welding parameters, the supplier should be able to show how they monitor and adjust these parameters during the manufacturing of rear seats welding jigs. If the supplier cannot provide clear and detailed information about their manufacturing process, it may cast doubt on the authenticity of their certifications.

Evaluate the Supplier's Investment in Quality

A supplier that is serious about maintaining their industry certifications is likely to invest in quality control measures. This can include advanced testing equipment, well - trained staff, and continuous improvement programs. Ask the supplier about their investment in quality. Do they have a dedicated quality control department? What kind of testing equipment do they use to ensure the quality of their rear seats welding jigs?

For instance, a supplier with certifications for high - precision welding jigs should have equipment such as coordinate measuring machines (CMM) to verify the dimensional accuracy of their products. If the supplier claims to have a high - quality product but does not seem to have the necessary resources to support it, their certifications may be questionable.

Explore Related Products and Services

As a rear seats welding jig supplier, we also offer related products such as Front Bumper Welding Fixture and Automotive Seat Welding Fixture. These products also adhere to strict industry standards and are backed by relevant certifications. Additionally, our Car Stamping Parts checking fixture is designed to ensure the accuracy of car stamping parts, further demonstrating our commitment to quality and compliance.

Conclusion

Verifying the industry certifications of a rear seats welding jig is a multi - step process that requires careful attention to detail. By requesting certification documents, contacting the certifying body, checking for third - party audits, considering the supplier's reputation and manufacturing process, and comparing with industry standards, you can ensure that you are dealing with a reliable supplier.

If you are in the market for high - quality rear seats welding jigs and want to discuss your requirements, we encourage you to reach out. We are committed to providing products that meet the highest industry standards and are backed by genuine certifications. Contact us to start a conversation about your purchasing needs.

References

- ISO 9001:2015 Quality management systems - Requirements

- ISO 14001:2015 Environmental management systems - Requirements with guidance for use

- IATF 16949:2016 Quality management systems - Particular requirements for the application of ISO 9001:2015 for automotive production and relevant service part organizations