Hey there! As a supplier of rear seats welding jigs, I often get asked, "How much does a rear seats welding jig cost?" Well, it's not a one - size - fits - all answer, and in this blog, I'll break down the factors that influence the cost and give you a better idea of what to expect.

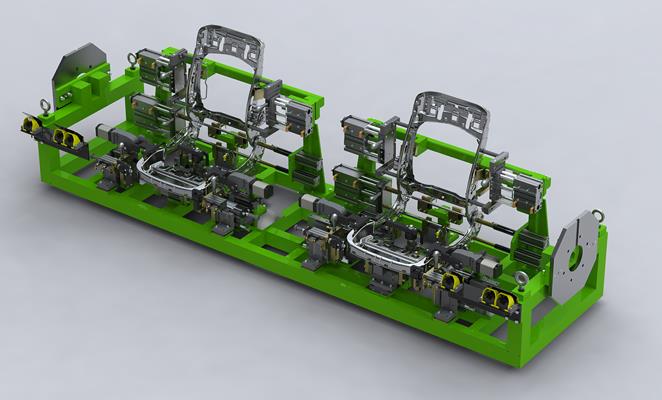

First off, let's understand what a rear seats welding jig is. It's a specialized tool used in the automotive manufacturing process. Its main job is to hold the rear seat components in place during the welding process, ensuring that everything is aligned correctly and the welds are of high quality. This is super important because any misalignment can lead to structural issues in the car seats, which is a big no - no.

Factors Affecting the Cost

Complexity of Design

The design of the rear seats welding jig plays a huge role in determining its cost. If the rear seats have a simple design with fewer components and straightforward welding requirements, the jig will be less expensive. For example, a basic two - piece rear seat with simple straight - line welds won't need a very complex jig.

On the other hand, if the rear seats are more advanced, with multiple layers, adjustable parts, or intricate shapes, the jig will need to be more sophisticated. It might require custom - made fixtures, precision - engineered components, and advanced clamping mechanisms. This kind of complexity drives up the cost significantly. You can check out more about automotive seat welding fixtures Automotive Seat Welding Fixture.

Material Quality

The materials used to make the rear seats welding jig are another major cost factor. There are different grades of steel, aluminum, and other alloys available, each with its own price point. High - quality materials are more durable, resistant to wear and tear, and can maintain their precision over a longer period.

For instance, using a premium - grade stainless steel for the jig's frame will ensure that it can withstand the high pressures and temperatures involved in the welding process. However, this type of steel is more expensive than a lower - grade alternative. Similarly, if the jig uses advanced polymers or composite materials for some of its components, the cost will go up due to the unique properties and manufacturing processes required for these materials.

Precision and Tolerance Requirements

In the automotive industry, precision is key. The rear seats welding jig needs to hold the components within very tight tolerances to ensure that the final product meets the required specifications. If the tolerance requirements are extremely tight, say within a few thousandths of an inch, the manufacturing process of the jig becomes more challenging.

Achieving such high precision often requires advanced machining techniques, such as CNC (Computer Numerical Control) machining, which is more expensive than traditional machining methods. Additionally, the jig will need to be inspected and calibrated more frequently to maintain its accuracy, adding to the overall cost.

Quantity of Production

The number of rear seats welding jigs you order also affects the cost. If you're only ordering one or two jigs, the per - unit cost will be higher because the setup costs for manufacturing, such as tooling and programming, are spread over a smaller number of units.

On the other hand, if you place a large - scale order, say for 100 or more jigs, the per - unit cost will decrease. This is because the fixed costs are distributed across a larger production volume, and the manufacturer can take advantage of economies of scale in purchasing materials and using production equipment more efficiently.

Cost Range

Based on my experience as a supplier, the cost of a rear seats welding jig can vary widely. For a simple, low - precision jig used for a basic rear seat design, you might be looking at a price range of $500 to $2,000. These jigs are usually made from standard materials and have relatively straightforward designs.

For a medium - complexity jig with moderate precision requirements, the cost can range from $2,000 to $5,000. These jigs are suitable for most standard rear seat designs in the automotive market and are made from better - quality materials with more advanced manufacturing techniques.

If you need a high - precision, custom - designed jig for a complex rear seat with advanced features, the cost can go well above $5,000, and in some cases, it can reach up to $10,000 or more. These jigs are often used in high - end automotive models or for specialized applications where the highest level of quality and precision is required.

Related Products

When it comes to automotive manufacturing, rear seats welding jigs are just one part of the equation. There are other related products that you might also be interested in. For example, Car Stamping Parts checking fixture is used to ensure the accuracy of car stamping parts. These fixtures are crucial for maintaining the quality of the exterior parts of the car, such as doors, fenders, and hoods.

Another related product is the Front Bumper Welding Fixture. Just like the rear seats welding jig, the front bumper welding fixture holds the bumper components in place during the welding process, ensuring a strong and precise weld.

Contact for Purchase and Negotiation

If you're in the market for a rear seats welding jig or any of the related products I mentioned, I'd love to have a chat with you. Whether you have specific requirements, need a custom - designed jig, or just want to get a better understanding of the costs involved, I'm here to help. Don't hesitate to reach out, and we can start a discussion about your needs and how I can provide you with the best solution at a competitive price.

References

- Industry knowledge and experience as a rear seats welding jig supplier.

- Automotive manufacturing industry standards and best practices.