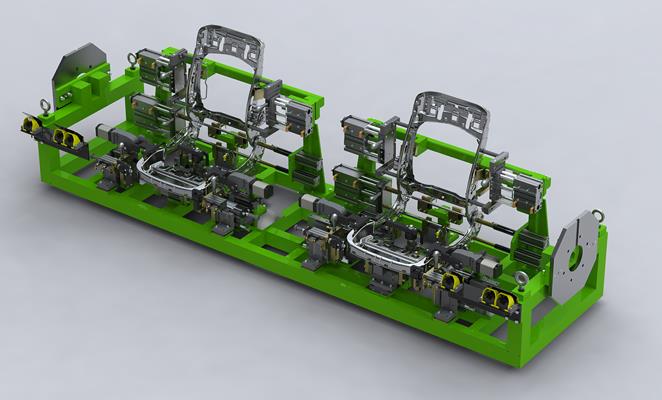

As a supplier of rear seats welding jigs, I've had extensive hands - on experience with these essential tools in the automotive manufacturing industry. Rear seats welding jigs play a crucial role in ensuring the accurate and efficient welding of rear seats, which are integral components of any vehicle. However, like any complex equipment, they come with their fair share of common problems.

1. Dimensional Accuracy Issues

One of the most prevalent problems with rear seats welding jigs is maintaining dimensional accuracy. The automotive industry demands extremely tight tolerances, and even the slightest deviation in the dimensions of the welding jig can lead to significant quality issues in the final product.

During the manufacturing process, wear and tear on the jig's components can cause changes in its dimensions. For example, the pins and locators that are used to position the seat parts precisely can become worn over time. This wear can result in the seat parts not being held in the correct position during welding, leading to misaligned welds and parts that do not fit together properly when assembled in the vehicle.

Another factor that can affect dimensional accuracy is thermal expansion. Welding generates a significant amount of heat, and if the welding jig is not designed to handle this heat effectively, it can expand unevenly. This uneven expansion can distort the jig's shape, causing the seat parts to be welded out of spec. To address these issues, we at [Our Company] (though not named explicitly here) use high - quality materials that have excellent dimensional stability and implement regular maintenance and calibration programs.

2. Fixture Clamping Problems

Proper clamping is essential for ensuring that the seat parts remain in place during the welding process. However, rear seats welding jigs often face clamping - related problems.

One common issue is insufficient clamping force. If the clamps do not apply enough force to hold the parts firmly, the parts can move during welding, resulting in poor - quality welds. This can be caused by worn - out clamp mechanisms, improper adjustment of the clamps, or the use of clamps that are not suitable for the specific seat parts being welded.

On the other hand, excessive clamping force can also be a problem. It can cause deformation of the seat parts, especially if they are made of thin or soft materials. This deformation can lead to fitment issues when the seats are installed in the vehicle. To solve these problems, we carefully select the appropriate clamping mechanisms based on the characteristics of the seat parts and ensure that they are properly adjusted and maintained.

3. Weld Spatter and Contamination

Weld spatter is a by - product of the welding process, and it can cause several problems for rear seats welding jigs. Spatter can accumulate on the jig's surfaces, including the clamping areas and locators. This accumulation can interfere with the proper positioning and clamping of the seat parts, leading to quality issues.

In addition, weld spatter can also cause contamination of the welding area. If the spatter is not removed regularly, it can mix with the welding materials and affect the quality of the welds. To deal with weld spatter and contamination, we design our welding jigs with features that make it easier to clean. For example, we use smooth surfaces and removable parts that can be easily cleaned or replaced. We also recommend regular cleaning and maintenance procedures to our customers to ensure the longevity and performance of the jigs.

4. Compatibility with Different Seat Designs

The automotive industry is constantly evolving, and new seat designs are being introduced regularly. Rear seats welding jigs need to be compatible with a wide range of seat designs to meet the needs of different vehicle models.

However, achieving compatibility can be challenging. Each seat design may have unique shapes, sizes, and features, which require different jig configurations. Designing a welding jig that can accommodate multiple seat designs often involves complex engineering and customization. At [Our Company], we have a team of experienced engineers who are skilled in designing flexible welding jigs. We use advanced CAD/CAM technology to simulate different seat designs and develop jigs that can be easily reconfigured for different applications. For more information on our diverse range of welding fixtures, you can visit Automotive Seat Welding Fixture.

5. Durability and Long - Term Performance

Rear seats welding jigs are subjected to high levels of stress and wear during their operation. They need to be durable enough to withstand repeated use over an extended period.

The materials used in the construction of the jig play a crucial role in its durability. Low - quality materials can lead to premature wear and failure of the jig. For example, if the structural components of the jig are made of weak steel, they may crack or deform under the stress of welding.

In addition to material selection, the design of the jig also affects its long - term performance. A well - designed jig will distribute the stress evenly across its components, reducing the risk of premature failure. We use high - strength materials and advanced manufacturing techniques to ensure the durability of our rear seats welding jigs. We also conduct rigorous testing to ensure that our jigs can meet the demanding requirements of the automotive manufacturing industry.

6. Ease of Use and Maintenance

Rear seats welding jigs need to be easy to use and maintain. If the jig is too complicated to operate, it can lead to operator errors, which can affect the quality of the welds.

Complex jigs may also require more time for setup and adjustment, which can reduce the overall productivity of the welding process. Similarly, if the jig is difficult to maintain, it can lead to longer downtime for repairs and maintenance.

At [Our Company], we focus on designing user - friendly welding jigs. We provide clear instructions and training to our customers on how to operate and maintain the jigs. Our jigs are designed with modular components that can be easily replaced or repaired, minimizing downtime and reducing maintenance costs.

7. Integration with Welding Equipment

Rear seats welding jigs need to be integrated seamlessly with the welding equipment. Any issues with this integration can lead to problems in the welding process.

For example, if the jig is not properly aligned with the welding gun, the welds may not be placed accurately. In addition, the electrical and pneumatic connections between the jig and the welding equipment need to be reliable. Faulty connections can cause disruptions in the welding process and affect the quality of the welds.

We work closely with our customers to ensure that our rear seats welding jigs are fully compatible with their existing welding equipment. We also provide technical support to help with the installation and integration process. If you are interested in other types of welding fixtures, such as Car Stamping Parts checking fixture or Front Bumper Welding Fixture, we can offer relevant solutions as well.

Conclusion

In conclusion, rear seats welding jigs face several common problems, including dimensional accuracy issues, fixture clamping problems, weld spatter and contamination, compatibility with different seat designs, durability and long - term performance, ease of use and maintenance, and integration with welding equipment. As a supplier of rear seats welding jigs, we are committed to addressing these problems through innovative design, the use of high - quality materials, and comprehensive after - sales support.

If you are in the automotive manufacturing industry and are looking for high - quality rear seats welding jigs, we invite you to contact us for a detailed discussion. Our team of experts will be happy to understand your specific requirements and provide you with the best solutions.

References

- Automotive Manufacturing Handbook: Covers general principles of automotive manufacturing, including welding and fixture design.

- Welding Technology Journal: Contains research and case studies on welding processes and fixture - related issues.

- Engineering Materials and Their Applications: Provides in - depth knowledge about materials used in welding jigs and their properties.