Hey there! As a supplier of auto door CMM holding jigs, I've seen firsthand how these little gadgets can really shake things up in auto door manufacturing plants. In this blog, I'll break down how our auto door CMM holding jigs can supercharge the productivity of your manufacturing plant.

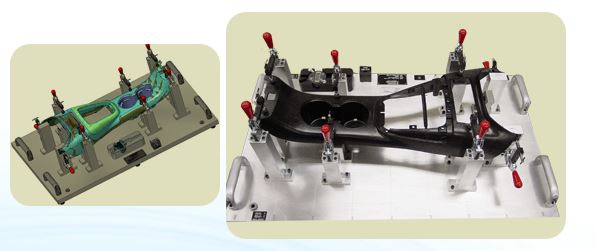

Let's start with the basics. A CMM, or Coordinate Measuring Machine, is a high - tech device used to measure the dimensions of a part with extreme precision. An auto door CMM holding jig is a specialized fixture that holds the auto door parts firmly in place during the CMM measurement process. Sounds simple, right? But the impact it has on productivity is huge.

1. Precision Measurement

One of the biggest pain points in auto door manufacturing is ensuring that every single door meets the strict quality standards. Even a tiny deviation in dimensions can lead to problems like poor fit, rattling, or even safety issues. That's where our auto door CMM holding jigs come in.

These jigs are designed to hold the door parts in the exact position required for accurate CMM measurement. They eliminate the risk of human error that can occur when manually positioning the parts. With precise measurements, manufacturers can quickly identify any parts that are out of spec and take corrective action right away. This means fewer defective doors, less rework, and ultimately, a more efficient production process.

For example, let's say you're manufacturing a batch of 100 auto doors. Without a proper holding jig, it might take a technician a long time to position each door correctly for measurement. And there's always a chance that the measurement might be inaccurate due to improper positioning. But with our auto door CMM holding jig, the technician can simply place the door in the jig, and the CMM can start measuring right away. This not only saves time but also ensures that the measurements are reliable.

2. Reduced Setup Time

In a manufacturing plant, time is money. Every minute spent on setting up a machine or a process is a minute that could be spent producing more parts. Our auto door CMM holding jigs are designed to significantly reduce setup time.

They are easy to install and can be quickly adjusted to accommodate different types of auto doors. Whether you're manufacturing sedan doors, SUV doors, or truck doors, our jigs can be configured to hold the parts securely. This means that your production team can switch between different door models with minimal downtime.

Let's compare it to the traditional method. Without a holding jig, the setup process for CMM measurement can be quite complex. The technician has to carefully position the door, use multiple clamps to hold it in place, and then make sure that it's level and aligned correctly. This can take up a significant amount of time, especially if they have to do it for each individual door. But with our holding jig, the setup is as simple as placing the door in the jig and locking it down. It's that easy!

3. Improved Operator Efficiency

Manufacturing is a labor - intensive process, and the efficiency of your operators plays a crucial role in overall productivity. Our auto door CMM holding jigs are designed to make the operator's job easier and more efficient.

By holding the door parts firmly in place, the jigs reduce the physical strain on the operators. They don't have to worry about holding the parts steady during the measurement process, which means they can focus on other important tasks. Additionally, the jigs are designed with ergonomics in mind, so they are easy to use and operate.

For instance, an operator who has to manually hold a heavy auto door in place for CMM measurement is likely to get tired quickly. This can lead to a decrease in productivity and an increase in the risk of accidents. But with our holding jig, the operator can work more comfortably and efficiently, resulting in higher output and better quality work.

4. Compatibility and Flexibility

In the auto industry, things change fast. New door designs are constantly being introduced, and manufacturers need to be able to adapt quickly. Our auto door CMM holding jigs are highly compatible and flexible.

They can be easily modified to accommodate new door designs or changes in manufacturing processes. This means that you don't have to invest in a new holding jig every time you introduce a new door model. You can simply make some adjustments to the existing jig, and it will be ready to use.

For example, if your company decides to start manufacturing a new type of auto door with a slightly different shape or size, our technicians can work with you to modify the holding jig to fit the new design. This saves you both time and money in the long run.

Related Products

If you're interested in other related products, we also offer Console Trim Bezels CMM Holding Fixture, which are great for ensuring the precise measurement of console trim bezels. And if you're an automotive door parts manufacturer, our Gauges For Automotive Door Parts Manufacturer can help you maintain high - quality standards. Also, check out our Door Parts CMM Holding Fixture for more options in holding auto door parts during measurement.

Conclusion

In conclusion, our auto door CMM holding jigs are a game - changer for auto door manufacturing plants. They improve precision, reduce setup time, enhance operator efficiency, and offer compatibility and flexibility. By investing in our holding jigs, you can significantly increase the productivity of your manufacturing plant, reduce costs, and improve the overall quality of your auto doors.

If you're interested in learning more about how our auto door CMM holding jigs can benefit your manufacturing plant, don't hesitate to reach out. We're always happy to have a chat and discuss your specific needs. Let's work together to take your auto door manufacturing to the next level!

References

- Automotive Manufacturing Handbook

- Precision Measurement in the Auto Industry: Best Practices and Case Studies