Hey there! As a supplier of auto door CMM holding jigs, I've seen firsthand how crucial these little devices are for getting accurate measurements on auto doors. In this blog, I'll break down how an auto door CMM holding jig ensures the correct alignment of the auto door during measurement. So, let's dive right in!

What is an Auto Door CMM Holding Jig?

First things first, let's talk about what an auto door CMM holding jig is. CMM stands for Coordinate Measuring Machine, which is a precision device used to measure the dimensions of an object. An auto door CMM holding jig is a custom - made fixture that holds the auto door in place during the measurement process. It's designed to mimic the real - world installation conditions of the door as closely as possible.

Ensuring Correct Positioning

One of the primary ways an auto door CMM holding jig ensures correct alignment is by precisely positioning the door. The jig has specific locating features that match the key points on the auto door. These locating features can be pins, blocks, or clamps. For example, there might be pins that fit into pre - drilled holes in the door frame. This way, the door can only be placed in one specific position on the jig.

When the door is placed on the jig, these locating features guide it into the exact spot where it needs to be for accurate measurement. This eliminates any guesswork and ensures that every time a door is measured, it's in the same position relative to the CMM. If the door isn't positioned correctly, the measurements taken by the CMM will be inaccurate, which can lead to all sorts of problems down the line, like poor - fitting doors or issues with the overall assembly of the vehicle.

Maintaining Stability

Another important aspect is stability. An auto door CMM holding jig is designed to hold the door firmly in place. It uses various clamping mechanisms to prevent any movement during the measurement process. Even the slightest movement can cause errors in the measurement.

For instance, hydraulic or pneumatic clamps can be used to apply a consistent and strong force to hold the door securely. These clamps are adjustable, so they can be set to the right pressure depending on the size and weight of the door. By keeping the door stable, the CMM can take accurate measurements of all the relevant dimensions, such as the length, width, and height of the door, as well as the positions of any holes or cutouts.

Compensating for Manufacturing Tolerances

Auto doors, like all manufactured parts, have some level of manufacturing tolerances. This means that there can be small variations in the dimensions of each door. An auto door CMM holding jig is designed to compensate for these tolerances.

The jig's locating features are often designed with a bit of flexibility. For example, a pin might have a slightly larger diameter hole in the jig to allow for a small amount of movement. This flexibility allows the jig to accommodate doors within the acceptable tolerance range while still ensuring that the door is held in a position that allows for accurate measurement. It's all about finding that balance between holding the door firmly and being able to work with the natural variations in the manufacturing process.

Mimicking Real - World Conditions

As I mentioned earlier, an auto door CMM holding jig is designed to mimic the real - world installation conditions of the door. This is crucial because the way the door is installed in the vehicle can affect its dimensions. For example, when the door is closed, it's under certain stresses and forces from the hinges, latches, and the vehicle body.

The jig can be designed to simulate these forces. It might have features that mimic the action of the hinges or the pressure exerted by the latch. By doing so, the measurements taken on the CMM are more representative of how the door will actually perform in the vehicle. This helps in detecting any potential issues early in the manufacturing process, such as a door that might not close properly due to incorrect dimensions under real - world conditions.

Importance of Accurate Alignment

Accurate alignment during measurement is super important. It ensures that the auto doors meet the required quality standards. If the measurements are off, the doors might not fit properly in the vehicle, which can lead to problems like water leaks, wind noise, and reduced security.

Moreover, accurate alignment helps in the overall efficiency of the manufacturing process. When the doors are measured accurately, it reduces the number of rejects and rework. This saves time and money for the automotive manufacturers. As a supplier of auto door CMM holding jigs, we understand the importance of providing high - quality jigs that can ensure this accurate alignment.

Our Product Offerings

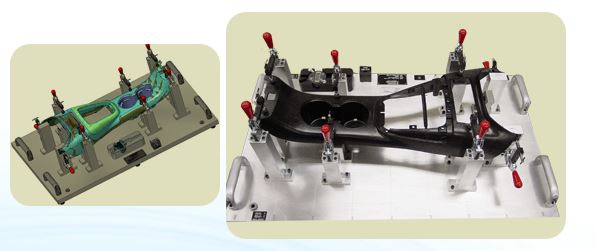

If you're in the market for high - quality auto door CMM holding jigs, we've got you covered. We offer a wide range of products, including Gauges For Automotive Door Parts Manufacturer, Door Parts CMM Holding Fixture, and Console Trim Bezels CMM Holding Fixture. Our jigs are designed and manufactured with the latest technology and highest quality standards to ensure the best possible alignment during measurement.

Let's Connect

If you're interested in learning more about our auto door CMM holding jigs or have any questions about how they can benefit your manufacturing process, don't hesitate to get in touch. We're always happy to discuss your specific needs and provide you with the right solutions. Whether you're a small - scale auto parts manufacturer or a large automotive company, we can work with you to ensure that your auto doors are measured accurately and efficiently.

References

- Automotive Manufacturing Handbook: Covers general principles of automotive part manufacturing and quality control.

- Coordinate Measuring Machine Technology Guides: Provides in - depth information on CMM operation and measurement techniques.