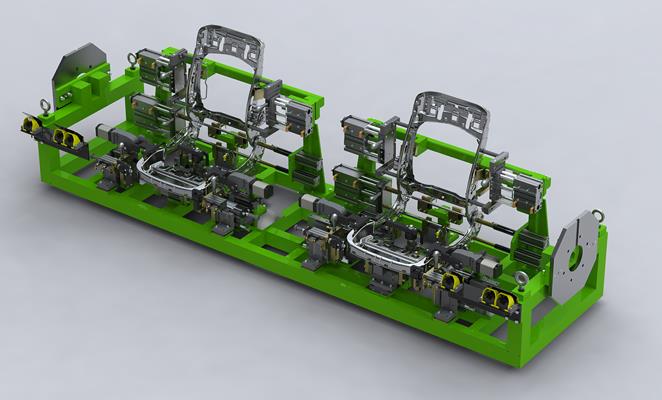

Customizing a rear seats welding jig is a process that involves a multitude of factors contributing to its overall cost. As a rear seats welding jig supplier, I've witnessed firsthand the complexity and nuances that play into determining the price of these specialized tools. In this blog, I'll break down the various elements that influence the cost of customizing a rear seats welding jig, providing you with a comprehensive understanding of what goes into this investment.

Design and Engineering

The initial phase of customizing a rear seats welding jig is the design and engineering process. This step is crucial as it lays the foundation for the entire project. The complexity of the design directly impacts the cost. A simple jig with basic functionality will naturally cost less than one with intricate features and advanced technology.

Engineers need to consider several factors during the design phase. They must ensure that the jig is compatible with the specific rear seats model it's intended for. This involves taking precise measurements and understanding the unique welding requirements of the seats. For instance, if the seats have complex shapes or require multiple welding points, the design will need to be more sophisticated, which in turn increases the cost.

Moreover, the use of advanced software and simulation tools during the design process adds to the expenses. These tools allow engineers to test the jig's performance virtually, identifying and rectifying any potential issues before the actual manufacturing begins. While this may seem like an added cost, it ultimately saves time and money by preventing costly mistakes during production.

Material Selection

The choice of materials for the rear seats welding jig is another significant factor in determining its cost. Different materials offer varying levels of durability, strength, and precision, and each comes with its own price tag.

High - quality steel is a popular choice for welding jigs due to its strength and durability. However, the cost of steel can vary depending on its grade and quality. Specialized alloys or heat - treated steels, which offer enhanced properties such as resistance to wear and deformation, are more expensive than standard steel.

Aluminum is another material that is sometimes used, especially when weight reduction is a priority. Aluminum is lighter than steel, which can be beneficial in certain applications. However, it also has its limitations in terms of strength, and the manufacturing processes for aluminum jigs can be more complex, leading to higher costs.

In addition to the base materials, the cost of any coatings or surface treatments applied to the jig must also be considered. Coatings can improve the jig's corrosion resistance, reduce friction, and enhance its overall performance. However, these treatments add to the overall cost of the product.

Manufacturing Processes

The manufacturing processes involved in creating a rear seats welding jig are diverse and can significantly impact the cost. Precision machining is often required to ensure that the jig meets the exact specifications of the design. This involves using advanced CNC (Computer Numerical Control) machines, which are capable of high - precision cutting, drilling, and milling operations.

CNC machining is a relatively expensive process due to the high cost of the equipment, the skilled labor required to operate it, and the time it takes to complete the machining operations. The more complex the design of the jig, the longer the machining time, and the higher the cost.

Welding is another critical manufacturing process. The quality of the welds directly affects the strength and reliability of the jig. Skilled welders are needed to ensure that the welds are strong and free of defects. The type of welding process used, such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding, can also impact the cost. TIG welding, for example, is generally more precise but also more time - consuming and expensive than MIG welding.

Assembly and testing are also important steps in the manufacturing process. The jig needs to be carefully assembled to ensure that all components fit together correctly. After assembly, it undergoes rigorous testing to verify its functionality and performance. Any issues identified during testing need to be addressed, which can add to the overall cost.

Customization and Special Features

One of the main reasons for customizing a rear seats welding jig is to meet specific requirements. Customization can include features such as adjustable fixtures, quick - change tooling, or integration with automated welding systems.

Adjustable fixtures allow the jig to be used with different rear seats models or to accommodate variations in the manufacturing process. While this adds flexibility, it also increases the complexity of the design and the manufacturing process, resulting in higher costs.

Quick - change tooling enables faster setup times between different welding operations. This can improve productivity but requires additional engineering and manufacturing efforts, leading to an increase in cost.

Integration with automated welding systems is becoming increasingly popular in the automotive industry. Automated systems can improve the accuracy and efficiency of the welding process. However, integrating the jig with these systems requires specialized knowledge and additional components, which drive up the cost.

Quality Control and Certification

Ensuring the quality of the rear seats welding jig is of utmost importance. Quality control measures are implemented throughout the manufacturing process to guarantee that the jig meets the required standards.

Inspection and testing procedures are carried out at various stages, from the raw material inspection to the final product testing. This includes dimensional inspections, functional tests, and performance evaluations. The cost of quality control equipment, such as coordinate measuring machines (CMMs) and non - destructive testing devices, as well as the labor required to operate them, adds to the overall cost.

In addition, obtaining relevant certifications can also increase the cost. Certifications such as ISO 9001 or automotive - specific quality standards demonstrate that the jig meets international quality requirements. The process of obtaining these certifications involves audits, documentation, and compliance with strict quality management systems.

Market Factors

Market factors also play a role in determining the cost of customizing a rear seats welding jig. Supply and demand dynamics can affect the price of raw materials and manufacturing services. If there is a high demand for steel or other key materials, their prices may increase, which in turn raises the cost of the jig.

Competition in the market can also influence the cost. As a rear seats welding jig supplier, we need to balance the cost of production with the need to remain competitive. In a highly competitive market, suppliers may offer more competitive prices to attract customers. However, this should not compromise the quality of the product.

Conclusion

In conclusion, the cost of customizing a rear seats welding jig is influenced by a wide range of factors, including design and engineering, material selection, manufacturing processes, customization, quality control, and market factors. Each of these elements contributes to the overall price, and understanding them is essential for making informed decisions.

If you're in the market for a customized rear seats welding jig, it's important to work with a reliable supplier who can provide you with a detailed breakdown of the costs. At our company, we have the expertise and experience to design and manufacture high - quality rear seats welding jigs tailored to your specific needs.

We also offer a range of related products, such as Automotive Seat Welding Fixture, Front Bumper Welding Fixture, and Car Stamping Parts checking fixture. If you're interested in learning more about our products or discussing your requirements, we encourage you to contact us for a detailed quote and to start a procurement discussion.

References

- "Automotive Manufacturing Technology Handbook"

- "Precision Machining and Welding Processes"

- Industry reports on automotive welding jigs and fixtures