Hey there! As a supplier of rear seats welding jigs, I often get asked about the training requirements for operating these essential pieces of equipment. In this blog post, I'll break down everything you need to know about training for using rear seats welding jigs effectively and safely.

Understanding the Basics of Rear Seats Welding Jigs

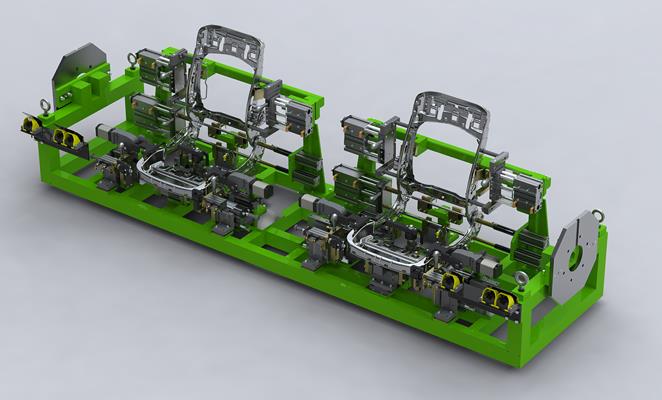

First off, let's talk a bit about what rear seats welding jigs are. These are specialized fixtures used in the automotive industry to hold rear seat components in place during the welding process. They ensure that the parts are aligned correctly, which is crucial for the quality and safety of the final product. A well - made welding jig can significantly improve the efficiency of the welding operation and reduce the chances of defects.

General Training Prerequisites

Before someone starts training to operate a rear seats welding jig, there are a few general prerequisites that are usually necessary. Basic mechanical aptitude is a must. Operators should have a good understanding of how machines work, including simple mechanisms like clamps, guides, and positioning devices. This knowledge helps them to quickly identify and troubleshoot any issues that may arise during the operation of the jig.

Another important prerequisite is safety training. Welding involves high temperatures, electrical currents, and potentially harmful fumes. Operators need to be well - versed in safety protocols, such as wearing appropriate personal protective equipment (PPE) like welding helmets, gloves, and aprons. They should also know how to handle emergency situations, like a fire or an electrical short - circuit.

Technical Training

Familiarization with the Jig

The first step in the technical training is to get operators familiar with the rear seats welding jig itself. This includes understanding its design, components, and how it functions. They need to learn about the different types of clamps and fixtures used to hold the rear seat parts in place. For example, some jigs use pneumatic clamps, while others may use hydraulic or manual ones.

Operators should also be taught how to properly set up the jig for different types of rear seats. This involves adjusting the positions of the clamps and guides according to the specific dimensions of the seat components. They need to know how to read the technical drawings and specifications provided by the manufacturer to ensure accurate setup.

Welding Techniques

Since the main purpose of the rear seats welding jig is to assist in the welding process, operators need to have a solid understanding of welding techniques. They should be trained in different types of welding methods commonly used in the automotive industry, such as spot welding and MIG (Metal Inert Gas) welding.

Spot welding is often used for joining thin sheets of metal, which is typical in rear seat construction. Operators need to learn how to set the correct welding parameters, such as the welding current, time, and pressure. Incorrect settings can lead to weak welds or damage to the seat components.

MIG welding, on the other hand, is used for more complex joints and can provide a stronger bond. Training in MIG welding includes learning how to handle the welding gun, control the wire feed, and maintain a stable arc.

Quality Control

Quality control is an integral part of operating a rear seats welding jig. Operators need to be trained on how to inspect the welded parts for defects. This includes checking for proper weld penetration, the absence of cracks or porosity, and correct alignment of the components.

They should know how to use inspection tools, such as calipers, gauges, and visual inspection methods. Any defective parts need to be identified early in the process to avoid costly rework or product recalls.

Hands - on Training

After the theoretical training, hands - on training is essential. This allows operators to apply the knowledge they have learned in a real - world setting. They start by practicing on sample rear seat components under the supervision of an experienced trainer.

During the hands - on training, operators get a feel for the actual operation of the welding jig. They learn how to load and unload the parts, adjust the jig settings on the fly, and troubleshoot minor issues. They also gain confidence in their welding skills as they perform multiple welding operations.

Continuous Training and Improvement

The automotive industry is constantly evolving, and so are the technologies used in rear seats welding jigs. That's why continuous training is necessary. Operators should be updated on the latest advancements in welding techniques, jig design, and quality control methods.

Regular refresher courses can help operators to stay sharp and improve their skills over time. This also ensures that they are able to operate the welding jigs efficiently and produce high - quality rear seats.

Additional Resources

If you're interested in learning more about related products, you can check out our Front Bumper Welding Fixture and Automotive Seat Welding Fixture. We also have information about Car Stamping Parts checking fixture on our website.

Contact Us for Purchasing

If you're in the market for a rear seats welding jig or have any questions about the training requirements, feel free to reach out to us. We're here to provide you with the best products and support to meet your needs. Our team of experts can guide you through the purchasing process and answer any technical questions you may have.

References

- Automotive Welding Handbook, various authors

- Industrial Machine Operation Manuals for Rear Seats Welding Jigs

- Safety Standards for Welding Operations in the Automotive Industry