Yo, what's up! I'm an auto door CMM holding jig supplier, and today I'm gonna spill the beans on the specs of these nifty jigs. So, if you're in the automotive industry or just curious about this stuff, stick around!

The Basics of Auto Door CMM Holding Jigs

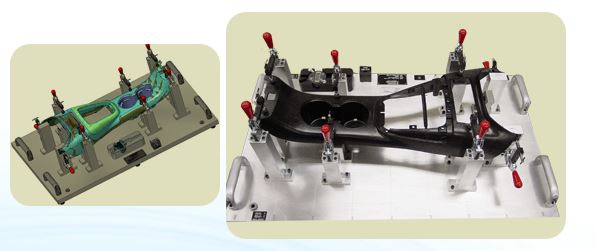

First things first, let's talk about what an auto door CMM (Coordinate Measuring Machine) holding jig is. It's a crucial tool used in the automotive manufacturing process. CMMs are used to measure the dimensions of auto door parts with high precision, and the holding jig plays a key role in keeping those parts in place during the measurement.

Think of it like a super - stable hand that holds a door part perfectly still while a super - accurate measuring device does its thing. Without a good holding jig, the measurements could be off, and that's a big no - no in the automotive world where precision is everything.

Material Specifications

The material of an auto door CMM holding jig is super important. It needs to be strong enough to hold the door parts firmly but also stable enough to not warp or change shape over time.

Aluminum

One of the most common materials we use is aluminum. Aluminum is lightweight, which makes it easy to handle and move around in the manufacturing facility. It's also corrosion - resistant, so it can stand up to the sometimes - harsh environment of an automotive production line. And it has good machinability, which means we can shape it into the exact form we need for different door parts.

Steel

Steel is another option. It's much stronger than aluminum, which makes it a great choice for holding heavier door parts or parts that require extra stability during measurement. However, it's also heavier, which can be a drawback in some situations. But if strength is your top priority, steel might be the way to go.

Design Specifications

The design of an auto door CMM holding jig is tailored to the specific door part it's meant to hold. Here are some key design aspects:

Customization

Each auto door is different, with unique shapes, sizes, and features. That's why our jigs are highly customizable. We work closely with our customers to understand the exact requirements of their door parts. For example, if a door part has a complex curve, the holding jig needs to be designed to support that curve perfectly.

Clamping Mechanisms

The clamping mechanisms on the holding jig are crucial. They need to be able to hold the door part securely without causing any damage. We use a variety of clamping methods, such as pneumatic clamps, which can provide a strong and consistent clamping force. There are also manual clamps for situations where a more hands - on approach is needed.

Alignment Features

Proper alignment is essential for accurate measurements. Our holding jigs are designed with alignment features like dowel pins and locators. These features ensure that the door part is positioned in the exact right place on the jig, so the CMM can take precise measurements.

Precision Specifications

In the automotive industry, precision is measured in microns. Our auto door CMM holding jigs are designed to meet extremely high precision standards.

Repeatability

Repeatability is a key factor. This means that every time a door part is placed on the jig, it should be held in the exact same position. Our jigs are engineered to have a high level of repeatability, so you can get consistent measurements every single time.

Tolerance

Tolerance refers to the acceptable amount of variation in the measurements. We design our jigs to have very tight tolerances. For example, we can achieve tolerances as low as ±0.05mm in some cases. This level of precision ensures that the door parts meet the strict quality standards of the automotive industry.

Compatibility with CMMs

Our auto door CMM holding jigs are designed to be fully compatible with a wide range of CMMs.

Interface Design

The interface between the holding jig and the CMM is carefully designed. It needs to be easy to connect and disconnect, so that the jig can be quickly swapped out for different door parts or different measurement tasks.

Data Transfer

Some modern CMMs are capable of digital data transfer. Our jigs are designed to work seamlessly with these systems, so that the measurement data can be accurately collected and analyzed.

Applications and Related Products

Auto door CMM holding jigs have a wide range of applications in the automotive industry. And we also offer some related products that can enhance the measurement process.

Door Parts CMM Holding Fixture

If you're looking for a fixture specifically designed for door parts, check out our Door Parts CMM Holding Fixture. It's designed to provide a secure and precise hold for various door components.

Console Trim Bezels CMM Holding Fixture

For those console trim bezels, we have a dedicated Console Trim Bezels CMM Holding Fixture. These bezels are often small and have intricate designs, so a specialized fixture is needed to ensure accurate measurements.

Gauges For Automotive Door Parts Manufacturer

We also offer Gauges For Automotive Door Parts Manufacturer. These gauges can be used in conjunction with our holding jigs to double - check the measurements and ensure the highest quality of the door parts.

Why Choose Our Auto Door CMM Holding Jigs

We take pride in our products. Our team of experts has years of experience in the automotive industry, and we use the latest manufacturing techniques and technologies to produce high - quality holding jigs.

We offer excellent customer service. We work closely with our customers from the initial design phase to the final delivery. If you have any questions or need any modifications to the jigs, we're here to help.

Let's Connect!

If you're in the market for auto door CMM holding jigs, I'd love to have a chat with you. Whether you need a standard jig or a custom - designed one, we've got you covered. Reach out to us, and let's start a conversation about how we can meet your automotive measurement needs.

References

- Automotive Manufacturing Handbook

- Precision Measurement in the Automotive Industry: Best Practices