Hey there! As a supplier of rear seats welding jigs, I've been keeping a close eye on the market trends in this area. In this blog, I'm gonna share with you what I've noticed and how these trends might impact your business if you're in the market for these jigs.

1. Technological Advancements

The first big trend I've seen is the rapid advancement of technology in the manufacturing of rear seats welding jigs. Automation has become a game - changer. More and more manufacturers are looking for jigs that can be integrated into automated welding systems. This is because automated welding using advanced jigs can significantly increase production efficiency and reduce human error.

For example, robotic welding systems that work in tandem with high - precision rear seats welding jigs can produce consistent welds at a much faster rate than manual welding. These jigs are often equipped with sensors and actuators that allow for real - time adjustments during the welding process. This means that if there's a slight variation in the position of the seat parts, the jig can correct it on the fly, ensuring a perfect weld every time.

Another technological aspect is the use of 3D printing in the prototyping and even production of welding jigs. 3D printing allows for quick and cost - effective creation of custom jigs. You can design a jig on a computer and have it printed in a matter of hours or days, depending on its complexity. This is a huge advantage for companies that need to test out new seat designs or make small - batch production runs.

2. Customization Demands

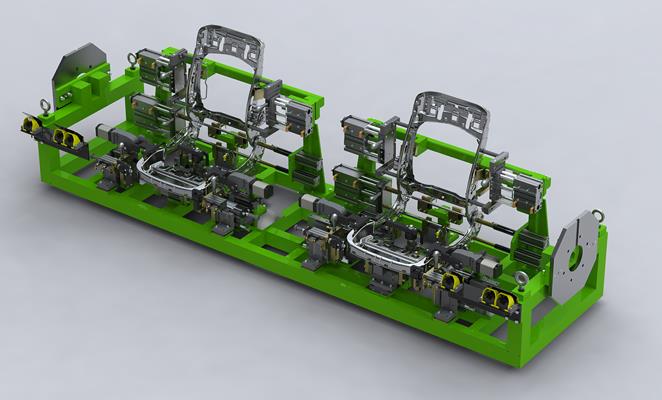

Customers are increasingly demanding customized rear seats welding jigs. Every car model has its own unique seat design, and manufacturers need jigs that can accommodate these differences. Whether it's a luxury sedan with a high - end leather seat or a compact car with a more basic design, the welding jigs need to be tailored to the specific requirements of each seat.

This customization trend also extends to the functionality of the jigs. Some customers might need jigs that can perform multiple welding operations in one go, while others might require jigs that are easy to reconfigure for different seat models. As a supplier, we've had to invest a lot in our R & D department to be able to meet these diverse customization needs.

For instance, we recently worked with a client who was developing a new electric SUV. Their rear seats had a complex design with multiple layers and unique shapes. We had to design a custom welding jig that could hold the seat parts in the exact position required for welding, while also allowing for easy access for the welding equipment. It was a challenging project, but in the end, we were able to deliver a jig that met their specific needs.

3. Quality and Durability

In the automotive industry, quality and durability are non - negotiable. Rear seats welding jigs need to be able to withstand the rigors of continuous use in a manufacturing environment. They need to maintain their precision over time, even with repeated welding operations.

Manufacturers are looking for jigs made from high - quality materials such as hardened steel or aluminum alloys. These materials offer a good balance between strength and weight, ensuring that the jigs are both durable and easy to handle. Additionally, surface treatments like heat - treating and coating are being used to enhance the corrosion resistance and wear resistance of the jigs.

We've also seen an increased focus on quality control during the manufacturing process of the jigs. We use advanced inspection techniques such as coordinate measuring machines (CMM) to ensure that every jig we produce meets the strict quality standards. This helps us to avoid any issues with the jigs during the welding process, which could lead to costly production delays.

4. Environmental Considerations

With the growing concern for the environment, the automotive industry is under pressure to be more sustainable. This trend has also affected the market for rear seats welding jigs. Manufacturers are looking for jigs that are energy - efficient and made from environmentally friendly materials.

For example, some jigs are now being designed to use less energy during the welding process. This can be achieved through better insulation and more efficient heating elements. Additionally, there's a push to use recycled materials in the production of the jigs. We've started exploring the use of recycled metals in our manufacturing process, which not only helps to reduce the environmental impact but also lowers the cost of production.

5. Integration with Other Manufacturing Processes

Rear seats welding jigs are no longer standalone tools. They need to be integrated with other manufacturing processes in the automotive production line. For example, they need to work seamlessly with the Car Stamping Parts checking fixture and the Front Bumper Welding Fixture.

This integration ensures a smooth flow of production and reduces the chances of errors. For instance, if the stamping parts are not correctly checked and aligned, it can lead to problems during the welding process of the rear seats. By integrating the welding jigs with other fixtures, we can create a more efficient and reliable production line.

6. Cost - Effectiveness

In today's competitive market, cost - effectiveness is a major consideration for manufacturers. They need to find rear seats welding jigs that offer a good balance between quality and price. As a supplier, we understand this need and are constantly looking for ways to reduce our production costs without compromising on the quality of the jigs.

One way we do this is by optimizing our manufacturing processes. We've streamlined our production line to reduce waste and increase productivity. We also source our raw materials from reliable suppliers at competitive prices. By doing these things, we're able to offer our customers high - quality welding jigs at a reasonable cost.

7. Industry Standards and Regulations

The automotive industry is highly regulated, and rear seats welding jigs need to comply with various industry standards and regulations. These standards ensure the safety and quality of the welded seats. For example, there are standards regarding the strength of the welds, the accuracy of the jig's positioning, and the materials used in the jigs.

As a supplier, we make sure that all our jigs are designed and manufactured in accordance with these standards. We keep a close eye on any changes in the regulations and update our products accordingly. This helps our customers to avoid any compliance issues and ensures that their production process runs smoothly.

Conclusion

So, those are the main market trends for rear seats welding jigs. As you can see, the market is evolving rapidly, driven by technological advancements, customization demands, and environmental concerns. If you're in the automotive manufacturing business and are in need of rear seats welding jigs, it's important to stay up - to - date with these trends to make the right purchasing decisions.

At our company, we're committed to staying at the forefront of these trends. We offer a wide range of Automotive Seat Welding Fixture, including custom - designed rear seats welding jigs that meet the highest quality and performance standards. If you're interested in learning more about our products or discussing your specific requirements, don't hesitate to get in touch. We'd love to have a chat with you and see how we can help you with your welding jig needs.

References

- Industry reports on automotive manufacturing trends

- Technical papers on welding technology and fixture design

- Interviews with automotive manufacturers and industry experts