Transporting an auto door CMM holding jig requires careful planning and execution to ensure its safety and functionality upon arrival. As a trusted supplier of auto door CMM holding jigs, I understand the challenges and importance of proper transportation. In this blog post, I'll share some valuable insights on how to transport these essential tools effectively.

Understanding the Auto Door CMM Holding Jig

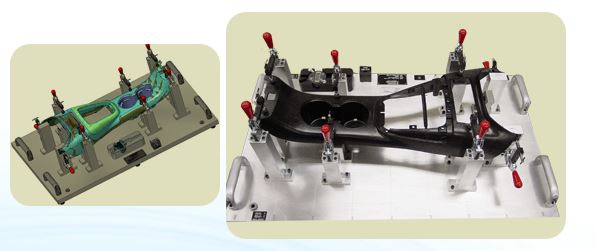

Before delving into the transportation process, it's crucial to understand what an auto door CMM holding jig is and why it's so important. An auto door CMM (Coordinate Measuring Machine) holding jig is a specialized fixture designed to hold auto door components securely in place during the measurement process using a CMM. This ensures accurate and precise measurements of the door parts, which are essential for quality control and manufacturing processes.

The Auto Door CMM Holding Fixture is a critical tool in the automotive industry, helping manufacturers ensure that their auto doors meet the required specifications and standards. Similarly, the Door Parts CMM Holding Fixture and Console Trim Bezels CMM Holding Fixture play vital roles in measuring and inspecting various automotive components.

Pre - transportation Preparations

1. Inspection

Before transporting the auto door CMM holding jig, conduct a thorough inspection. Check for any signs of damage, loose parts, or wear and tear. This step is crucial as any pre - existing issues can be exacerbated during transportation. Make sure all the components are in good working condition and that the jig is calibrated correctly.

2. Cleaning

Clean the jig to remove any dirt, debris, or contaminants. A clean jig is less likely to be damaged during transportation, and it also ensures that it will function properly when it reaches its destination. Use appropriate cleaning agents and tools, and pay special attention to the contact points and measurement surfaces.

3. Disassembly (if necessary)

In some cases, disassembling the auto door CMM holding jig into smaller, more manageable parts can make transportation easier. However, this should be done with extreme care. Keep track of all the parts, label them properly, and make sure you have a detailed plan for reassembly. Ensure that all the fasteners and connectors are securely stored to prevent loss.

4. Packaging

Proper packaging is one of the most critical aspects of transporting an auto door CMM holding jig. Use high - quality packaging materials such as foam, bubble wrap, and sturdy cardboard boxes. The packaging should provide sufficient cushioning to protect the jig from shocks, vibrations, and impacts during transit.

For smaller parts, place them in sealed plastic bags and label them clearly. If the jig has any sharp edges or protruding parts, cover them with protective caps or padding to prevent damage to the packaging and other items during transportation.

Choosing the Right Transportation Method

1. Ground Transportation

Ground transportation, such as trucks, is a common choice for transporting auto door CMM holding jigs. It offers several advantages, including flexibility in terms of pick - up and delivery locations, and it can be relatively cost - effective for shorter distances.

When choosing a trucking company, look for one with experience in transporting delicate and high - value equipment. Ensure that the truck has a well - maintained suspension system to minimize vibrations during transit. Also, make sure the truck is equipped with appropriate tie - down points to secure the packaged jig firmly in place.

2. Air Transportation

For long - distance or international shipments, air transportation may be a better option. It is faster, which reduces the risk of damage due to extended transit times. However, it can be more expensive.

When shipping by air, make sure the jig is packaged according to the airline's regulations. Airlines have strict rules regarding the size, weight, and packaging of cargo. You may also need to obtain any necessary permits or documentation for international shipments.

3. Sea Transportation

If you are shipping the auto door CMM holding jig overseas and time is not a critical factor, sea transportation can be a cost - effective option. However, it has a longer transit time, and the jig needs to be well - protected against the harsh marine environment, including humidity, saltwater, and rough seas.

Use waterproof and corrosion - resistant packaging materials. Also, make sure the container is properly secured and that the jig is stowed in a way that minimizes the risk of movement during the voyage.

During Transportation

1. Securing the Jig

Regardless of the transportation method, securing the auto door CMM holding jig properly is essential. Use straps, ropes, or other securing devices to prevent the jig from shifting or moving during transit. In a truck, it should be firmly tied down to the floor or walls of the cargo area. In an airplane or a shipping container, follow the specific securing guidelines provided by the carrier.

2. Monitoring

If possible, monitor the transportation process. Some modern transportation methods allow for real - time tracking of the shipment. This enables you to keep an eye on the location and condition of the jig. In case of any delays or issues, you can take appropriate action promptly.

Post - transportation Checks

1. Inspection

Once the auto door CMM holding jig arrives at its destination, conduct another thorough inspection. Check for any signs of damage that may have occurred during transportation. Look for cracks, dents, or misaligned parts.

2. Reassembly (if applicable)

If the jig was disassembled for transportation, reassemble it carefully following the detailed plan you created earlier. Make sure all the parts are properly aligned and tightened.

3. Calibration

After reassembly, calibrate the auto door CMM holding jig to ensure that it is still accurate and reliable. This step is crucial as any minor misalignment or damage during transportation can affect the measurement results.

Conclusion

Transporting an auto door CMM holding jig requires a comprehensive approach that includes pre - transportation preparations, choosing the right transportation method, proper handling during transit, and post - transportation checks. By following these guidelines, you can ensure that your auto door CMM holding jig arrives at its destination safely and in good working condition.

If you are in the market for high - quality auto door CMM holding jigs or need more information on their transportation and usage, I encourage you to reach out to me. I'm here to assist you with all your automotive measurement fixture needs and can provide you with the best solutions for your business.

References

- Automotive Manufacturing Handbook: A comprehensive guide to automotive manufacturing processes, including quality control and measurement techniques.

- Transportation Best Practices for Delicate Equipment: Industry - specific guidelines on transporting high - value and delicate equipment.