In the dynamic landscape of automotive manufacturing, the seamless integration of various equipment is crucial for enhancing efficiency, quality, and overall productivity. As a leading supplier of rear seats welding jigs, we understand the significance of exploring integration possibilities with other manufacturing equipment to meet the evolving demands of the industry. This blog post delves into the potential integration scenarios and the benefits they bring to automotive production lines.

Integration with Robotic Welding Systems

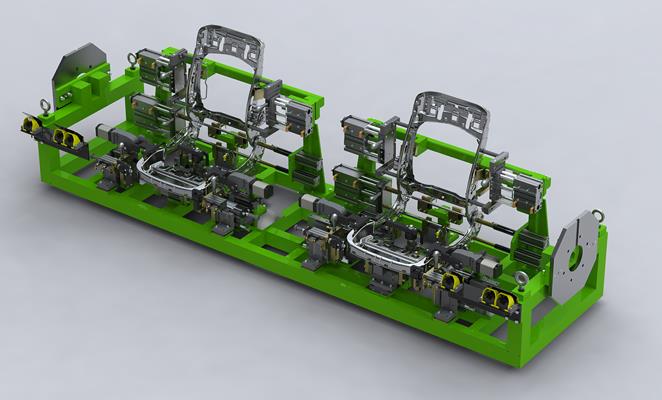

One of the most common and effective integration possibilities for rear seats welding jigs is with robotic welding systems. Robots offer high precision, repeatability, and speed, making them ideal partners for welding operations. By integrating our rear seats welding jigs with robotic welding systems, manufacturers can achieve consistent weld quality and reduce human error.

Robotic welding systems can be programmed to perform complex welding tasks with ease, ensuring that each weld meets the required specifications. The rear seats welding jigs provide a stable and accurate platform for the robot to operate on, holding the seat components in place during the welding process. This integration not only improves the quality of the welds but also increases the production rate, as the robot can work continuously without fatigue.

Moreover, the integration of robotic welding systems with rear seats welding jigs allows for greater flexibility in production. Manufacturers can easily adjust the welding parameters and the position of the robot to accommodate different seat designs and production requirements. This flexibility enables them to respond quickly to changes in customer demand and market trends.

Integration with Conveyor Systems

Another important integration possibility is with conveyor systems. Conveyor systems are widely used in automotive manufacturing to transport parts and components between different workstations. By integrating our rear seats welding jigs with conveyor systems, manufacturers can create a continuous and efficient production line.

The rear seats welding jigs can be designed to be compatible with the conveyor system, allowing the seat components to be loaded onto the jigs and transported to the welding station automatically. Once the welding is complete, the welded seats can be unloaded from the jigs and transported to the next workstation for further processing. This integration eliminates the need for manual handling of the seat components, reducing the risk of damage and improving the overall efficiency of the production line.

In addition, the integration of conveyor systems with rear seats welding jigs enables real-time monitoring and control of the production process. Manufacturers can use sensors and control systems to track the movement of the seat components on the conveyor system and ensure that the welding process is carried out smoothly. This real-time monitoring allows for quick identification and resolution of any issues that may arise during the production process, minimizing downtime and improving productivity.

Integration with Inspection Equipment

Quality control is a critical aspect of automotive manufacturing. To ensure that the rear seats meet the required quality standards, it is essential to integrate the rear seats welding jigs with inspection equipment. Inspection equipment, such as vision systems and coordinate measuring machines (CMMs), can be used to inspect the welds and the dimensions of the welded seats.

By integrating our rear seats welding jigs with inspection equipment, manufacturers can perform in-line inspection of the welded seats, immediately after the welding process. This real-time inspection allows for quick identification of any defects or non-conformities, enabling manufacturers to take corrective actions before the seats are sent to the next workstation. This integration not only improves the quality of the final product but also reduces the cost of rework and scrap.

Furthermore, the integration of inspection equipment with rear seats welding jigs provides valuable data for process improvement. Manufacturers can analyze the inspection results to identify trends and patterns in the welding process, allowing them to optimize the welding parameters and improve the overall quality of the welds. This data-driven approach to process improvement helps manufacturers to stay competitive in the market by continuously improving the quality of their products.

Integration with Car Stamping Parts checking fixture

Car stamping parts checking fixtures are used to ensure the accuracy and quality of car stamping parts. By integrating our rear seats welding jigs with Car Stamping Parts checking fixture, manufacturers can ensure that the seat components are properly aligned and fitted before the welding process.

The car stamping parts checking fixture can be used to verify the dimensions and the shape of the seat components, ensuring that they meet the required specifications. Once the seat components are checked and approved, they can be loaded onto the rear seats welding jigs for the welding process. This integration helps to prevent welding defects caused by misaligned or poorly fitted seat components, improving the overall quality of the welded seats.

Integration with Front Bumper Welding Fixture

The front bumper is an important component of the car, and its welding quality directly affects the safety and appearance of the vehicle. By integrating our rear seats welding jigs with Front Bumper Welding Fixture, manufacturers can create a more comprehensive and efficient production line.

The integration of the rear seats welding jigs with the front bumper welding fixture allows for the simultaneous production of the rear seats and the front bumper. This not only saves time and resources but also ensures that the two components are properly aligned and fitted when they are assembled onto the car. This integration improves the overall quality of the vehicle and enhances the customer's driving experience.

Integration with Automotive Seat Welding Fixture

As a supplier of rear seats welding jigs, we also offer Automotive Seat Welding Fixture for other types of seats, such as front seats and middle seats. By integrating our rear seats welding jigs with Automotive Seat Welding Fixture, manufacturers can create a unified and efficient seat production line.

The integration of different types of automotive seat welding fixtures allows for the seamless production of all types of seats in the car. Manufacturers can easily switch between different seat designs and production requirements, using the same set of equipment and production processes. This integration not only improves the efficiency of the production line but also reduces the cost of equipment and maintenance.

Conclusion

In conclusion, the integration of rear seats welding jigs with other manufacturing equipment offers numerous benefits for automotive manufacturers. By integrating with robotic welding systems, conveyor systems, inspection equipment, Car Stamping Parts checking fixture, Front Bumper Welding Fixture, and Automotive Seat Welding Fixture, manufacturers can improve the quality of the welds, increase the production rate, reduce the cost of production, and enhance the overall efficiency of the production line.

As a leading supplier of rear seats welding jigs, we are committed to providing our customers with high-quality products and innovative solutions. We have extensive experience in integrating our welding jigs with various types of manufacturing equipment and can help our customers design and implement the most suitable integration方案 for their specific production requirements.

If you are interested in learning more about the integration possibilities of our rear seats welding jigs with other manufacturing equipment or would like to discuss your specific needs, please feel free to contact us. We look forward to working with you to improve your automotive production process and achieve your business goals.

References

- Automotive Manufacturing Technology Handbook, edited by John A. Schey

- Robotics in Manufacturing, by John J. Craig

- Conveyor Systems Design Handbook, by CEMA