Hey there! As a supplier of auto door CMM holding jigs, I've been keeping a close eye on the industry trends. In this blog, I'll share with you what's going on in this field and how these trends might affect our business.

1. Precision and Accuracy

First off, precision and accuracy are becoming more and more important. Auto manufacturers are demanding higher - quality products, and that means the CMM (Coordinate Measuring Machine) holding jigs need to be spot - on. With the development of advanced manufacturing technologies, the tolerance requirements for auto doors are getting stricter.

For example, in the past, a tolerance of a few millimeters might have been acceptable for some auto door parts. But now, we're talking about tolerances in the sub - millimeter range. Our jigs need to hold the auto door parts firmly and accurately during the measurement process so that the CMM can get precise data. This is crucial for ensuring that the auto doors fit perfectly into the vehicle body, reducing noise and vibration, and improving overall performance.

To meet these requirements, we're constantly upgrading our manufacturing processes. We're using high - precision machining equipment and advanced materials. For instance, some of our jigs are made from special alloys that have excellent dimensional stability, which helps to maintain accuracy over time. You can check out our Door Parts CMM Holding Fixture for more details on how we achieve this level of precision.

2. Customization

Another big trend is customization. Every auto manufacturer has its own unique requirements for auto doors, and that means our CMM holding jigs need to be customized accordingly. We can't just offer a one - size - fits - all solution anymore.

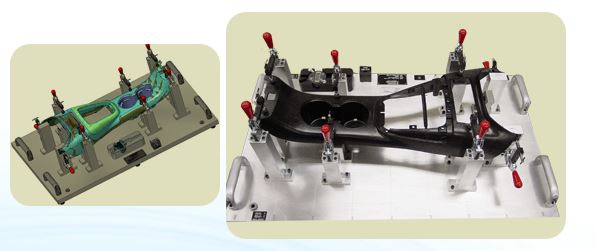

Some auto manufacturers might be working on new - style auto doors with unique shapes and sizes. Others might have specific requirements for the measurement points or the way the parts are held during the CMM process. We need to work closely with our customers to understand their needs and design jigs that are tailored to their specific applications.

For example, if a manufacturer is developing a luxury car with high - end auto doors, they might require jigs that can handle delicate materials and complex geometries. On the other hand, a mass - market car manufacturer might need jigs that are cost - effective and can be used for high - volume production. We've got the expertise to design and manufacture customized jigs for different scenarios. You can learn more about our customized solutions for automotive door parts manufacturers on our Gauges For Automotive Door Parts Manufacturer page.

3. Automation and Integration

Automation is taking over the manufacturing industry, and the auto door CMM holding jig sector is no exception. There's a growing demand for jigs that can be integrated into automated production lines.

In an automated production environment, the CMM holding jigs need to be able to work seamlessly with other equipment, such as robots and conveyors. They should be able to load and unload auto door parts automatically, and the measurement process should be fully integrated into the overall production flow.

This not only improves efficiency but also reduces the risk of human error. For example, a robot can pick up an auto door part and place it accurately in the CMM holding jig, and then the jig can hold the part in place while the CMM takes measurements. All of this can be controlled by a central computer system, which ensures a smooth and continuous production process.

We're investing a lot in research and development to make our jigs more automated and integrated. We're also collaborating with other technology companies to develop new solutions. You can see some of our innovative automated solutions on our Console Trim Bezels CMM Holding Fixture page, which gives you an idea of how we're approaching this trend.

4. Lightweighting

With the increasing focus on fuel efficiency and environmental friendliness in the automotive industry, lightweighting has become a key trend. Auto manufacturers are looking for ways to reduce the weight of their vehicles, and this includes the auto doors.

Lighter auto doors not only help to improve fuel economy but also make the vehicles more agile. Our CMM holding jigs need to be designed to handle these lightweight materials, such as aluminum alloys and carbon fiber composites. These materials have different properties compared to traditional steel, so our jigs need to be adjusted accordingly.

For example, lightweight materials might be more prone to deformation, so our jigs need to hold them gently but firmly to prevent any damage during the measurement process. We're constantly testing and optimizing our jigs to ensure that they can work effectively with these new lightweight materials.

5. Data - Driven Manufacturing

Data is king in today's manufacturing world, and the auto door CMM holding jig industry is no different. We're collecting a lot of data during the manufacturing and measurement processes. This data can be used to improve the quality of our jigs and the overall production process.

For example, we can analyze the measurement data from the CMM to identify any trends or patterns. If we notice that a particular type of jig is causing more measurement errors, we can use the data to make adjustments to the design or manufacturing process. We can also use data analytics to predict when a jig might need maintenance or replacement, which helps to reduce downtime and improve productivity.

In addition, we're using data to communicate better with our customers. We can provide them with detailed reports on the performance of our jigs and how they're contributing to the quality of their auto doors. This transparency builds trust and helps us to establish long - term partnerships.

Contact for Purchase and Collaboration

If you're in the market for high - quality auto door CMM holding jigs, I'd love to hear from you. Whether you're an auto manufacturer looking for customized solutions or a parts supplier in need of reliable jigs, we've got the expertise and products to meet your needs. We're committed to providing the best products and services, and we're always open to new challenges and opportunities. So, don't hesitate to reach out and start a conversation about your requirements.

References

- Industry reports on automotive manufacturing trends

- Technical papers on precision measurement and fixture design

- Interviews with auto manufacturers and industry experts