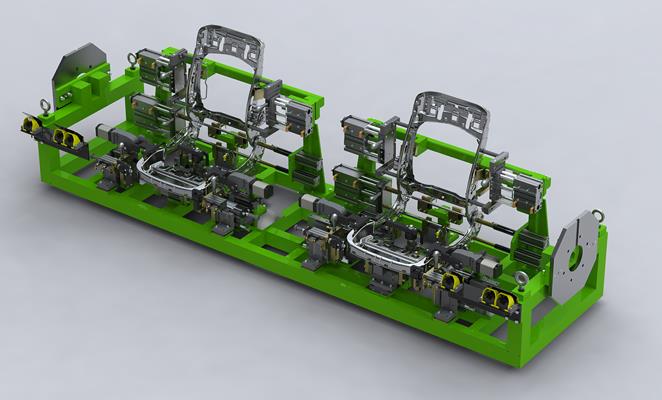

Hey there! I'm a supplier of rear seats welding jigs, and while these tools are super handy in the automotive manufacturing world, they're not without their drawbacks. Let's dive into the disadvantages of using a rear seats welding jig.

High Initial Investment

One of the biggest downsides of rear seats welding jigs is the high upfront cost. These jigs are precision - engineered pieces of equipment. To ensure they can accurately hold and position the rear seat components during the welding process, they need to be made with high - quality materials and advanced manufacturing techniques.

For example, the frames of these jigs are often made from high - strength steel or aluminum alloys. The clamping mechanisms are designed to be extremely precise, which requires sophisticated machining and assembly. All of this adds up to a significant initial investment. Smaller automotive manufacturers or startups might find it hard to justify spending such a large amount of money on a single piece of equipment, especially when they're still trying to establish themselves in the market.

Limited Flexibility

Rear seats welding jigs are typically designed for a specific type of rear seat model. Once a jig is manufactured for a particular seat design, it's pretty much locked into that configuration. If there are any changes in the seat design, such as a different shape, size, or the addition of new components, the existing jig may become obsolete.

Let's say an automaker decides to update the rear seat design to include a new lumbar support feature. The old welding jig won't be able to accommodate this change, and a new jig will have to be designed and manufactured. This lack of flexibility can be a major headache for automotive companies that are constantly innovating and updating their product lines. It also means additional costs for new jigs and potential downtime during the transition period.

Maintenance and Calibration Requirements

Rear seats welding jigs require regular maintenance and calibration to ensure they continue to function accurately. Over time, the components of the jig can wear out due to the constant stress and vibration during the welding process. The clamping mechanisms may loosen, and the positioning elements may become misaligned.

For instance, the pins that hold the seat components in place can get worn down, leading to inaccurate positioning during welding. This can result in defective welds, which can compromise the quality and safety of the rear seats. Regular maintenance, including cleaning, lubrication, and replacement of worn - out parts, is essential.

Calibration is also crucial. The jig needs to be calibrated to ensure that the seat components are welded in the correct position every time. This requires specialized equipment and skilled technicians. If the calibration is not done correctly, it can lead to a high rate of rejected parts, which increases production costs.

Space Requirements

These welding jigs can be quite large and bulky. They need a significant amount of floor space in the manufacturing facility. In a busy automotive production line, where space is often at a premium, this can be a real problem.

The large size of the jigs also makes them difficult to move around. If there are any changes in the production layout or if the jigs need to be relocated for maintenance or other reasons, it can be a time - consuming and challenging task. This can disrupt the normal flow of production and cause delays.

Training Requirements

Operating a rear seats welding jig requires specialized training. Workers need to understand how to set up the jig, load the seat components correctly, and operate the welding equipment in conjunction with the jig.

The training process can be time - consuming and expensive. New employees need to be trained on the specific features and functions of the jig, as well as safety procedures. If there are any changes in the jig design or the welding process, existing employees also need to be retrained. This can put a strain on the resources of the manufacturing company, especially if they have a high turnover rate.

Dependency on Welding Technology

Rear seats welding jigs are closely tied to the welding technology being used. If there are advancements in welding technology, such as the development of a more efficient or precise welding method, the existing jigs may not be compatible.

For example, if a new type of laser welding technology becomes available that offers better weld quality and faster production speeds, the current jigs may not be able to work with this new technology. This means that the company either has to continue using the old welding technology, which may put them at a competitive disadvantage, or invest in new jigs that are compatible with the new welding technology.

Potential for Defects

Despite their precision design, rear seats welding jigs can still contribute to defects in the welded parts. If the jig is not properly maintained or calibrated, as mentioned earlier, it can lead to inaccurate positioning of the seat components during welding. This can result in weak welds, misaligned parts, or other quality issues.

In addition, the design of the jig itself can sometimes cause problems. For example, if the clamping force is not evenly distributed, it can cause distortion in the seat components during welding. These defects can lead to costly rework or even product recalls, which can damage the reputation of the automotive manufacturer.

Cost of Spare Parts

The spare parts for rear seats welding jigs can be quite expensive. Since these jigs are specialized pieces of equipment, the spare parts are often custom - made and not readily available off - the shelf.

For example, if a unique clamping arm on the jig breaks, the company may have to wait for the manufacturer to produce a new one. This can lead to production delays, and the cost of the spare part itself can be high due to the custom manufacturing process.

If you're in the automotive industry and are considering using rear seats welding jigs, it's important to weigh these disadvantages against the benefits. Of course, there are also many positive aspects to using these jigs, such as improved accuracy and repeatability in the welding process.

If you're interested in learning more about other types of welding fixtures, you can check out our Front Bumper Welding Fixture, Automotive Seat Welding Fixture, and Car Stamping Parts checking fixture.

If you have any questions or want to discuss your specific requirements for rear seats welding jigs or other welding fixtures, feel free to reach out. We're here to help you make the best decision for your manufacturing needs.

References

- Automotive Manufacturing Handbook, various authors

- Journal of Automotive Engineering, multiple issues

- Industry reports on automotive welding technology and equipment