As a supplier of rear seats welding jigs, I've witnessed firsthand the dynamic interplay between new materials and the automotive manufacturing landscape. The development of new materials is a powerful force that reshapes not only the products but also the tools and processes used in their creation. In this blog, I'll explore how the evolution of new materials impacts rear seats welding jigs, touching on aspects such as design, performance, and future prospects.

Impact on Design

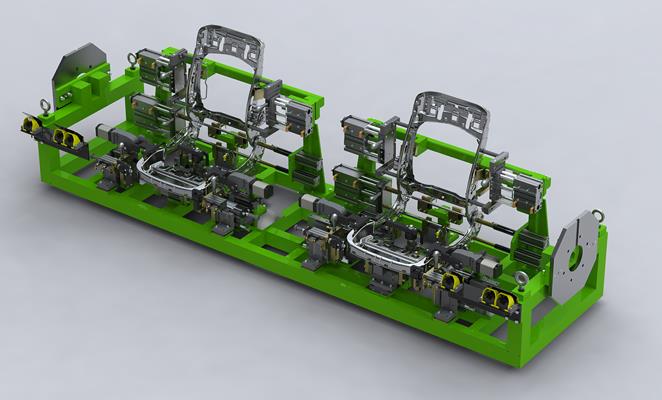

The emergence of new materials often brings unique properties that challenge traditional design concepts of rear seats welding jigs. For instance, advanced composite materials, which are increasingly used in automotive seat construction, offer high strength-to-weight ratios and excellent corrosion resistance. However, these materials also require special handling during the welding process.

When welding composite materials, the heat distribution and pressure control need to be precisely managed. This means that the design of the welding jigs must be more sophisticated to accommodate these requirements. We may need to incorporate advanced sensors and control systems into the jigs to monitor and adjust the welding parameters in real - time. For example, infrared sensors can be used to measure the temperature distribution during welding, ensuring that the composite materials are not over - heated, which could lead to material degradation.

In addition, new materials may have different shapes and geometries. Lightweight metals, such as aluminum alloys, are commonly used in modern automotive seats to reduce weight. These materials are often formed into complex shapes to meet both structural and aesthetic requirements. As a result, the welding jigs need to be designed with greater flexibility to hold and position these irregularly shaped parts accurately. This may involve the use of modular or adjustable fixtures that can be easily reconfigured for different seat models and part geometries.

Influence on Performance

The performance of rear seats welding jigs is significantly affected by the development of new materials. One of the key performance indicators is the accuracy of welding. New materials may have different thermal expansion coefficients compared to traditional materials. For example, plastics and polymers used in seat components expand and contract at different rates when heated and cooled. This can cause dimensional changes during the welding process, leading to misalignment and poor welding quality.

To address this issue, welding jigs need to be designed with compensation mechanisms. For instance, we can use materials with similar thermal expansion properties in the jig construction or incorporate adjustable elements that can counteract the dimensional changes of the seat parts. This ensures that the welding process maintains high accuracy, resulting in strong and reliable welds.

Another important performance aspect is the durability of the welding jigs. New materials may require more aggressive welding processes, such as high - energy laser welding or friction stir welding, to achieve proper bonding. These processes generate high levels of heat and mechanical stress, which can wear out the jigs more quickly. Therefore, we need to select materials for the jigs that can withstand these harsh conditions. For example, using high - strength steels or advanced ceramics in critical areas of the jig can improve its wear resistance and extend its service life.

The efficiency of welding is also influenced by new materials. Some new materials, such as magnesium alloys, have a high reactivity with oxygen, which can lead to oxidation during welding. This requires the use of special shielding gases or protective coatings to prevent oxidation. The welding jigs need to be designed to accommodate these additional requirements, such as providing channels for the flow of shielding gases. By optimizing the jig design, we can reduce the time and cost associated with the welding process, improving overall production efficiency.

Future Prospects

Looking ahead, the development of new materials will continue to drive innovation in rear seats welding jigs. The trend towards more sustainable and environmentally friendly materials, such as bio - based polymers and recycled metals, will pose new challenges and opportunities. These materials may have different physical and chemical properties compared to traditional materials, requiring us to develop new welding techniques and jig designs.

For example, bio - based polymers may have lower melting points and different bonding mechanisms. This will require the development of low - temperature welding processes and jigs that can provide gentle and precise pressure during bonding. Additionally, as the automotive industry moves towards electric vehicles, the demand for lightweight and high - performance seat materials will increase. This will further stimulate the development of advanced welding jigs that can handle these new materials effectively.

In the era of Industry 4.0, the integration of smart technologies into rear seats welding jigs will become more prevalent. New materials will work in tandem with sensors, actuators, and data analytics to create intelligent welding systems. These systems can self - diagnose problems, optimize welding parameters in real - time, and communicate with other manufacturing equipment. For example, a smart welding jig can detect the quality of a weld immediately after the process and adjust the subsequent welding operations accordingly, reducing waste and improving product quality.

Links to Related Products

If you are interested in other types of welding fixtures related to the automotive industry, you can explore our Car Stamping Parts checking fixture, Automotive Seat Welding Fixture, and Front Bumper Welding Fixture. These products are designed to meet the diverse needs of automotive manufacturing, ensuring high - quality welding and efficient production.

Conclusion and Call to Action

In conclusion, the development of new materials has a profound impact on rear seats welding jigs, from design to performance and future prospects. As a supplier of rear seats welding jigs, we are committed to staying at the forefront of these changes, continuously innovating and improving our products to meet the evolving needs of the automotive industry.

If you are in the market for high - quality rear seats welding jigs or have any questions about how our products can adapt to new materials, we invite you to contact us for a procurement discussion. We look forward to collaborating with you to achieve greater success in the automotive manufacturing field.

References

- "Advanced Materials in Automotive Manufacturing" - A research report on the latest trends in automotive materials.

- "Welding Technology for New Materials" - A technical publication focusing on welding processes and techniques for emerging materials.

- "Automotive Seat Design and Manufacturing" - A comprehensive guidebook on the design and production of automotive seats, including the role of welding jigs.