Hey there! I'm a supplier of auto door CMM holding jigs, and I've been in this game for quite a while. Training operators to use these jigs properly is super important, and I'm here to share some tips on how to do it right.

Understanding the Auto Door CMM Holding Jig

First things first, let's talk about what an auto door CMM holding jig is. It's a specialized tool used to hold auto door parts in place during coordinate measuring machine (CMM) inspections. These jigs are crucial for ensuring accurate measurements and high - quality production.

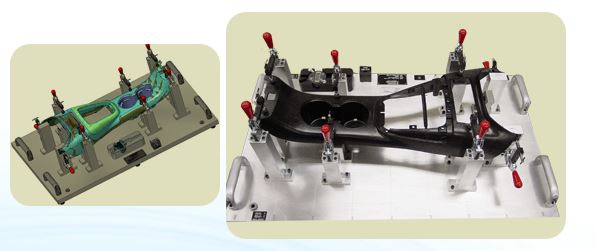

Our Auto Door CMM Holding Fixture is designed with precision and durability in mind. It's made from high - quality materials that can withstand the rigors of daily use in a manufacturing environment. The jig has a unique design that allows for easy loading and unloading of auto door parts, which is essential for efficient production.

Pre - training Preparation

Before you start training your operators, you need to make sure they have a basic understanding of the CMM and the auto door parts being measured. You can start by providing some general information about the CMM, such as how it works and what it's used for.

It's also a good idea to give the operators a tour of the manufacturing facility and show them where the CMM and the holding jigs are located. This will help them get familiar with the working environment and build their confidence.

Another important step is to provide the operators with the necessary safety training. Working with CMMs and holding jigs can be dangerous if proper safety procedures are not followed. Make sure they know how to use personal protective equipment (PPE) like safety glasses and gloves, and how to handle the jigs safely.

Hands - on Training

Once the operators have a basic understanding of the CMM and the safety procedures, it's time for hands - on training. This is where they'll learn how to actually use the auto door CMM holding jig.

Start by demonstrating how to load an auto door part onto the jig. Show them how to align the part correctly and how to secure it in place using the locking mechanisms on the jig. Make sure to explain the importance of proper alignment, as this will directly affect the accuracy of the CMM measurements.

Next, teach the operators how to operate the CMM in conjunction with the holding jig. Show them how to set up the CMM for the specific auto door part being measured, including how to enter the correct measurement parameters.

During the hands - on training, it's important to give the operators plenty of time to practice. Let them try loading and unloading parts, setting up the CMM, and taking measurements on their own. Provide them with feedback and guidance as they go, and encourage them to ask questions.

Troubleshooting Training

Even with proper training, operators may encounter problems when using the auto door CMM holding jig. That's why it's important to provide them with troubleshooting training.

Teach the operators how to identify common problems, such as misaligned parts, loose locking mechanisms, or issues with the CMM itself. Show them how to perform basic troubleshooting steps, like checking the alignment of the part, tightening the locking screws, or restarting the CMM.

It's also a good idea to have a troubleshooting guide available for the operators to refer to. This guide should include a list of common problems, their possible causes, and the steps to take to fix them.

Ongoing Training and Support

Training doesn't end after the initial hands - on session. You need to provide ongoing training and support to your operators to ensure they continue to use the auto door CMM holding jig correctly.

One way to do this is to schedule regular refresher courses. These courses can cover topics like new features of the jig or the CMM, updated safety procedures, or advanced measurement techniques.

You can also encourage your operators to share their experiences and any problems they've encountered with the holding jig. This will help you identify areas where additional training may be needed and improve the overall training program.

Benefits of Proper Training

Properly trained operators can bring many benefits to your manufacturing facility. First of all, they'll be able to use the auto door CMM holding jig more efficiently, which will lead to increased productivity.

Accurate measurements are also crucial for quality control. When operators know how to use the holding jig correctly, they'll be able to obtain more accurate measurements, which means fewer defective auto door parts and higher customer satisfaction.

In addition, well - trained operators are less likely to cause accidents or damage to the equipment. This will save you money on repairs and maintenance costs in the long run.

Other Related Holding Fixtures

In addition to our Auto Door CMM Holding Fixture, we also offer other types of CMM holding fixtures, such as the Door Parts CMM Holding Fixture and the Console Trim Bezels CMM Holding Fixture. These fixtures are designed to meet the specific needs of different auto parts manufacturers.

Conclusion

Training operators to use an auto door CMM holding jig is a process that requires time, effort, and patience. By following the steps outlined in this blog, you can ensure that your operators are well - trained and able to use the jig effectively.

If you're interested in our auto door CMM holding jigs or other related fixtures, feel free to reach out to us for more information. We're always happy to discuss your specific needs and how our products can help improve your manufacturing process.

References

- General knowledge about CMMs and manufacturing processes

- In - house experience with training operators on using holding jigs