Hey there! As a supplier of rear seats welding jigs, I've seen firsthand how important it is to store these tools properly. A well - stored welding jig not only extends its lifespan but also ensures consistent and high - quality welding results. In this blog, I'll share some tips on how to store a rear seats welding jig properly.

1. Clean the Jig Thoroughly Before Storage

Before you even think about putting your rear seats welding jig away, you gotta clean it up. Welding jigs are exposed to all sorts of debris during the welding process, like metal shavings, spatter, and dust. If you don't clean these off, they can cause corrosion over time.

Start by using a wire brush to remove any loose debris. Pay special attention to the clamping areas and the surfaces that come into contact with the parts. After that, you can use a degreaser to clean off any oil or grease. Make sure to rinse it well and dry it completely. A damp jig is a breeding ground for rust, and that's the last thing you want.

2. Choose the Right Storage Location

The location where you store your rear seats welding jig matters a whole lot. You want a place that's dry, clean, and well - ventilated. Avoid areas that are prone to moisture, like basements or near open windows where rain can get in.

If possible, store the jig indoors. A dedicated storage room or a workshop is ideal. If you have to store it outside, make sure it's covered with a waterproof tarp. And don't just leave it on the ground. Elevate it on a pallet or a rack to prevent it from sitting in water or dirt.

3. Protect the Jig from Physical Damage

Rear seats welding jigs are precision tools, and even a small dent or scratch can affect their performance. When storing the jig, make sure it's not in a place where it can be bumped into or knocked over.

If you have multiple jigs, store them in an organized way so that they don't rub against each other. You can use foam padding or rubber bumpers to separate them. Also, be careful when moving the jig in and out of storage. Use proper lifting equipment to avoid dropping it.

4. Check for and Address Any Wear and Tear

Before you store the jig long - term, take a good look at it for any signs of wear and tear. Check the clamping mechanisms, the alignment pins, and the welding contacts. If you notice any issues, like loose bolts or worn - out parts, fix them before storage.

Replacing a small part now can save you a lot of headaches later. You don't want to pull out the jig after a few months and find that it's not working properly because you didn't address a minor problem.

5. Lubricate Moving Parts

The moving parts of a rear seats welding jig, such as the clamps and hinges, need to be lubricated regularly. Lubrication reduces friction and prevents rust. Before storing the jig, apply a light coat of lubricant to these parts.

Make sure to use a lubricant that's suitable for the materials used in the jig. Some lubricants can damage certain metals or plastics, so read the label carefully.

6. Document the Storage

It's a good idea to keep a record of when you stored the jig and any maintenance or repairs you did before storage. This documentation can be really helpful if you need to refer back to it later.

You can use a simple spreadsheet or a notebook to record the details. Include the date of storage, the condition of the jig, and any parts that were replaced. This way, when you take the jig out of storage, you'll have a clear idea of its history.

Why Proper Storage is Crucial

Proper storage of rear seats welding jigs is crucial for several reasons. First of all, it saves you money. A well - stored jig will last longer, which means you won't have to replace it as often.

Secondly, it ensures the quality of your welding work. A damaged or poorly maintained jig can lead to inaccurate welds, which can affect the safety and performance of the rear seats.

Finally, it improves efficiency. When you take the jig out of storage and it's in good condition, you can start using it right away without having to spend time on repairs or adjustments.

Related Products

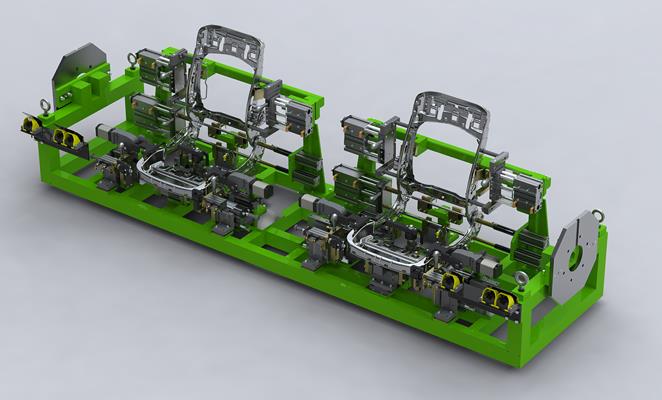

If you're in the automotive welding industry, you might also be interested in other types of welding fixtures. For example, the Automotive Seat Welding Fixture is designed specifically for welding automotive seats. It offers precise alignment and clamping, ensuring high - quality welds.

Another useful product is the Front Bumper Welding Fixture. This fixture helps in welding front bumpers accurately, which is important for the overall appearance and safety of the vehicle.

And if you're involved in checking car stamping parts, the Car Stamping Parts checking fixture can be a great addition to your toolkit. It allows you to quickly and accurately check the dimensions and quality of car stamping parts.

Reach Out for More

If you're looking for high - quality rear seats welding jigs or have any questions about storage or usage, don't hesitate to reach out. We're here to help you get the most out of your welding tools. Whether you're a small - scale workshop or a large - scale automotive manufacturer, we've got the products and expertise to meet your needs.

References

- General knowledge from years of experience in the rear seats welding jig supply industry.

- Industry best practices for tool storage and maintenance.