Recycling a rear seats welding jig is not only an environmentally responsible approach but also a cost - effective strategy for businesses. As a rear seats welding jig supplier, I have witnessed firsthand the importance of proper recycling processes. In this blog, I will share some effective ways to recycle a rear seats welding jig.

Understanding the Rear Seats Welding Jig

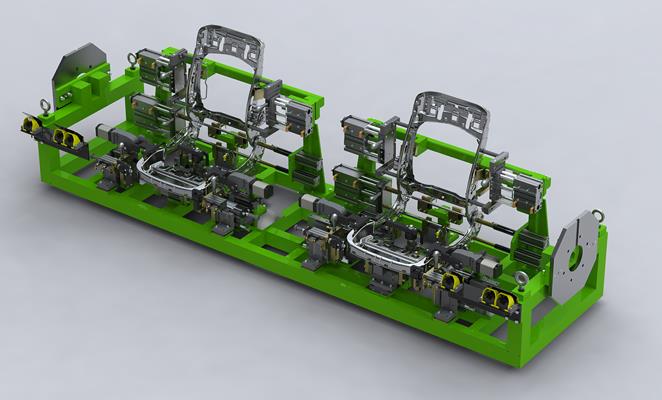

Before delving into the recycling process, it's crucial to understand what a rear seats welding jig is. A rear seats welding jig is a specialized tool used in the automotive manufacturing industry. It holds the rear seat components in place during the welding process, ensuring accurate and consistent welds. These jigs are typically made of high - quality metals such as steel and aluminum, which makes them suitable for recycling.

Disassembly and Inspection

The first step in recycling a rear seats welding jig is disassembly. This process involves carefully taking apart the jig to separate different components. During disassembly, it's important to inspect each part for damage or wear. Components that are still in good condition can be reused or refurbished, while damaged parts can be recycled.

For example, the steel frames of the jig can be inspected for cracks or excessive wear. If the frames are in good shape, they can be cleaned, repainted, and reused in new jigs. On the other hand, if there are parts that are severely damaged, they can be sent to a metal recycling facility.

Recycling of Metals

As mentioned earlier, rear seats welding jigs are mainly made of metals. Steel and aluminum are the most common metals used in these jigs. Recycling these metals not only conserves natural resources but also reduces energy consumption compared to producing new metals from raw materials.

When recycling steel, it is melted down in a furnace. The impurities are removed, and the molten steel can be used to produce new steel products. Aluminum recycling is even more energy - efficient, as it requires only about 5% of the energy needed to produce new aluminum from bauxite ore.

There are many metal recycling facilities that specialize in handling automotive components. These facilities have the necessary equipment and expertise to recycle the metals from rear seats welding jigs effectively.

Refurbishment and Reuse

In some cases, instead of completely recycling the jig, it can be refurbished and reused. Refurbishment involves cleaning, repairing, and upgrading the jig to make it suitable for further use. This approach can save a significant amount of money and resources.

For instance, if the clamping mechanisms of the jig are worn out, they can be replaced with new ones. The surface of the jig can be sandblasted and repainted to improve its appearance and corrosion resistance. After refurbishment, the jig can be sold as a refurbished product, which is often more affordable than a brand - new jig.

Recycling of Non - Metal Components

In addition to metals, rear seats welding jigs may also contain non - metal components such as plastics and rubber. These components can also be recycled, although the process may be more complex.

Plastic components can be sorted by type and then melted down and reprocessed into new plastic products. Rubber components can be ground into small pieces and used in the production of new rubber products or as additives in other materials.

Environmental and Economic Benefits

Recycling rear seats welding jigs offers both environmental and economic benefits. From an environmental perspective, it reduces the amount of waste sent to landfills and conserves natural resources. It also helps to reduce the energy consumption and greenhouse gas emissions associated with the production of new jigs.

Economically, recycling can save costs for both the supplier and the customer. For suppliers, recycling reduces the cost of raw materials and production. For customers, refurbished or recycled jigs can be purchased at a lower price, which can improve their bottom line.

Related Products in the Automotive Industry

In the automotive industry, there are many other related products that also require proper handling and recycling. For example, the Front Bumper Welding Fixture is another important tool used in the manufacturing process. Similar to rear seats welding jigs, front bumper welding fixtures can also be recycled or refurbished to save resources.

The Car Stamping Parts checking fixture is used to ensure the accuracy of car stamping parts. Recycling these fixtures can contribute to a more sustainable automotive manufacturing process.

Moreover, the Automotive Seat Welding Fixture is directly related to rear seats welding jigs. By implementing proper recycling strategies for these fixtures, the automotive industry can move towards a more circular economy.

Conclusion

Recycling a rear seats welding jig is a multi - step process that involves disassembly, inspection, metal recycling, refurbishment, and recycling of non - metal components. It offers significant environmental and economic benefits for both suppliers and customers in the automotive industry.

As a rear seats welding jig supplier, I encourage businesses to adopt recycling practices. By doing so, we can contribute to a more sustainable future while also improving our own bottom line. If you are interested in purchasing rear seats welding jigs, refurbished jigs, or have any questions about recycling, please feel free to contact us for further discussion. We are always ready to provide you with the best solutions and support for your automotive manufacturing needs.

References

- "Automotive Manufacturing Handbook", John Wiley & Sons

- "Recycling in the Automotive Industry", Springer Publishing