Hey there! As a supplier of auto door CMM holding jigs, I often get asked about how these nifty tools ensure the safety of operators during use. Well, buckle up because I'm about to take you on a ride through the world of auto door CMM holding jigs and their safety features.

First off, let's talk about what an auto door CMM holding jig is. It's a specialized fixture designed to hold auto door components in place during coordinate measuring machine (CMM) inspections. These inspections are crucial for ensuring that the parts meet the required specifications and quality standards. Without a proper holding jig, it would be nearly impossible to get accurate measurements, which could lead to defective parts and potential safety hazards down the line.

So, how does an auto door CMM holding jig keep operators safe? One of the key safety features is its robust design. These jigs are built to be sturdy and durable, capable of withstanding the rigors of daily use in a manufacturing environment. They're typically made from high-quality materials like aluminum or steel, which provide excellent strength and stability. This means that the jig won't shift or move during the inspection process, reducing the risk of accidents or injuries caused by unstable equipment.

Another important safety aspect is the jig's ergonomic design. We understand that operators have to work with these jigs for long periods of time, so we've made sure to design them with comfort and ease of use in mind. The jigs are equipped with handles and grips that are easy to hold and maneuver, reducing the strain on the operator's hands and wrists. Additionally, the jig's height and positioning can be adjusted to suit the operator's needs, ensuring a comfortable working posture and minimizing the risk of repetitive strain injuries.

In addition to its physical design, an auto door CMM holding jig also incorporates several safety features to protect operators from potential hazards. For example, many jigs are equipped with safety interlocks that prevent the CMM from operating if the jig is not properly installed or secured. This helps to prevent accidents caused by the CMM coming into contact with the operator or other objects in the workspace. Some jigs also have built-in sensors that detect if the part is properly seated in the jig, ensuring that the inspection is accurate and reducing the risk of false readings.

Furthermore, we provide comprehensive training and support to our customers to ensure that they understand how to use the auto door CMM holding jig safely and effectively. Our team of experts is available to answer any questions and provide guidance on installation, operation, and maintenance. We also offer on-site training sessions to help operators get up to speed quickly and ensure that they're using the jig correctly.

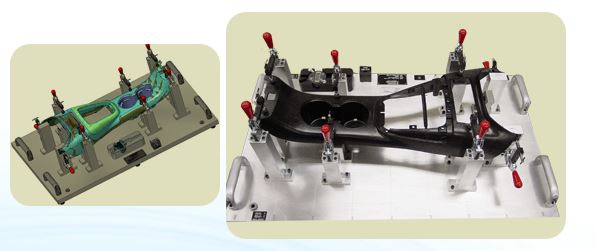

Now, let's take a look at some of the specific products we offer. We have a wide range of auto door CMM holding jigs available, including the Auto Door CMM Holding Fixture, the Door Parts CMM Holding Fixture, and the Console Trim Bezels CMM Holding Fixture. Each of these jigs is designed to meet the specific needs of our customers and provide accurate and reliable measurements.

The Auto Door CMM Holding Fixture is specifically designed for holding auto door components during CMM inspections. It features a modular design that allows for easy customization and adjustment, making it suitable for a wide range of door sizes and shapes. The jig is also equipped with a variety of clamping mechanisms to ensure that the part is securely held in place during the inspection process.

The Door Parts CMM Holding Fixture is designed for holding individual door parts, such as hinges, latches, and handles. It provides a stable and accurate platform for measuring these parts, ensuring that they meet the required specifications. The jig is also easy to use and can be quickly set up for different parts, reducing downtime and increasing productivity.

The Console Trim Bezels CMM Holding Fixture is designed for holding console trim bezels during CMM inspections. It features a unique design that allows for easy access to all sides of the bezel, ensuring that accurate measurements can be taken. The jig is also adjustable, allowing it to accommodate different bezel sizes and shapes.

In conclusion, an auto door CMM holding jig is an essential tool for ensuring the accuracy and quality of auto door components. By incorporating robust design, ergonomic features, and safety interlocks, these jigs help to keep operators safe during use. If you're in the market for an auto door CMM holding jig, we invite you to check out our products and contact us to discuss your specific needs. We're confident that we can provide you with the right solution for your manufacturing process.

References

- "Coordinate Measuring Machines: Principles and Applications" by John A. Black and Donald C. Dobson

- "Ergonomics in Manufacturing: Designing for People at Work" by Karen B. Straker and Mark W. Burgess

- "Safety in Manufacturing: A Guide to Best Practices" by the Occupational Safety and Health Administration (OSHA)