In the dynamic landscape of automotive manufacturing, the efficiency and precision of welding processes are of paramount importance. Among the critical components in vehicle assembly, the A-pillar plays a vital role in providing structural support and safety. As a leading supplier of A PILLAR welding fixtures, I often encounter a common question: Can an A PILLAR welding fixture be used for robotic welding? In this blog post, I will delve into this topic, exploring the feasibility, advantages, and considerations of using A PILLAR welding fixtures in robotic welding applications.

Understanding A PILLAR Welding Fixtures

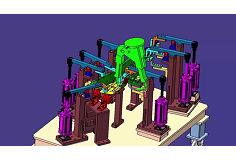

Before we discuss the compatibility with robotic welding, it is essential to understand what A PILLAR welding fixtures are and their significance in the manufacturing process. A PILLAR welding fixtures are specialized tools designed to hold and position A-pillar components accurately during the welding process. These fixtures ensure that the A-pillar parts are aligned correctly, maintaining the required dimensional accuracy and quality.

The design of A PILLAR welding fixtures is highly customized, taking into account the specific geometry and requirements of the A-pillar components. They are typically made of high-strength materials such as steel or aluminum and are equipped with precision clamping mechanisms to secure the parts firmly in place. The fixtures may also incorporate features such as locators, guides, and sensors to facilitate the welding process and ensure consistent results.

The Rise of Robotic Welding in Automotive Manufacturing

Robotic welding has revolutionized the automotive industry, offering numerous benefits in terms of productivity, quality, and flexibility. Robots can perform repetitive welding tasks with high precision and consistency, reducing human error and improving overall efficiency. They can also work in hazardous environments, such as high-temperature or high-pressure areas, without compromising safety.

In addition to their precision and efficiency, robotic welding systems offer greater flexibility compared to traditional manual welding methods. Robots can be programmed to weld different types of joints, shapes, and sizes, making them suitable for a wide range of applications. They can also be easily integrated into automated production lines, allowing for seamless coordination with other manufacturing processes.

Feasibility of Using A PILLAR Welding Fixtures for Robotic Welding

The answer to the question of whether an A PILLAR welding fixture can be used for robotic welding is a resounding yes. In fact, the combination of A PILLAR welding fixtures and robotic welding systems offers several advantages that can significantly enhance the manufacturing process.

One of the primary advantages of using A PILLAR welding fixtures in robotic welding is the ability to achieve high precision and repeatability. The fixtures ensure that the A-pillar components are held in the correct position and orientation, allowing the robot to perform the welding operation with accuracy. This results in consistent weld quality and dimensional accuracy, reducing the need for rework and improving overall product quality.

Another advantage is the increased productivity and efficiency. Robotic welding systems can operate at high speeds, performing multiple welds in a short period. The use of A PILLAR welding fixtures allows for quick and easy loading and unloading of the A-pillar components, minimizing downtime and maximizing throughput. This can lead to significant cost savings and improved competitiveness in the market.

In addition to precision and productivity, the combination of A PILLAR welding fixtures and robotic welding systems offers greater flexibility. The fixtures can be designed to accommodate different types of A-pillar components, allowing for easy changeover between different models or production runs. The robot can also be programmed to perform different welding patterns and techniques, depending on the specific requirements of the A-pillar.

Considerations for Using A PILLAR Welding Fixtures in Robotic Welding

While the use of A PILLAR welding fixtures in robotic welding offers numerous benefits, there are several considerations that need to be taken into account to ensure successful implementation.

One of the key considerations is the design and compatibility of the fixture with the robotic welding system. The fixture must be designed to fit the specific robot model and welding process, taking into account factors such as the robot's reach, payload capacity, and welding parameters. The fixture should also be equipped with appropriate interfaces and connectors to allow for seamless integration with the robot.

Another important consideration is the programming and setup of the robotic welding system. The robot must be programmed to perform the welding operation accurately and efficiently, taking into account the geometry and position of the A-pillar components held by the fixture. The programming should also include appropriate safety measures and error handling routines to ensure the safety of the operators and the integrity of the welding process.

In addition to design and programming, the maintenance and calibration of the A PILLAR welding fixtures and robotic welding system are crucial for ensuring consistent performance. The fixtures should be regularly inspected and maintained to ensure that they are in good working condition and that the clamping mechanisms are functioning properly. The robotic welding system should also be calibrated regularly to ensure accurate positioning and welding parameters.

Conclusion

In conclusion, the use of A PILLAR welding fixtures in robotic welding is a viable and beneficial solution for automotive manufacturers. The combination of high precision, productivity, and flexibility offered by these technologies can significantly enhance the manufacturing process and improve overall product quality. However, careful consideration must be given to the design, compatibility, programming, and maintenance of the fixtures and robotic welding system to ensure successful implementation.

As a supplier of A PILLAR welding fixtures, I am committed to providing high-quality products and solutions that meet the specific needs of my customers. If you are interested in learning more about our Auto Pillar Parts Welding Fixture or Robotic Welding Fixture Line, or if you have any questions or inquiries, please do not hesitate to contact me. I look forward to the opportunity to discuss how our products can help you improve your manufacturing process and achieve your business goals.

References

- "Robotic Welding in Automotive Manufacturing: A Review," Journal of Manufacturing Processes, Vol. 25, 2017.

- "Design and Optimization of Welding Fixtures for Automotive Body Assembly," International Journal of Advanced Manufacturing Technology, Vol. 81, 2015.

- "Automotive Welding Technology: Principles and Applications," CRC Press, 2016.