In the automotive manufacturing industry, ensuring the precise measurement of auto doors is crucial for maintaining high - quality standards. Auto door CMM (Coordinate Measuring Machine) holding jigs play a pivotal role in this process by guaranteeing the stability of the auto door during measurement. As a trusted auto door CMM holding jig supplier, we understand the significance of this component and its impact on the overall manufacturing process.

The Importance of Stable Auto Door Measurement

Accurate measurement of auto doors is essential for multiple reasons. Firstly, it ensures proper fit and alignment within the vehicle body. A well - measured auto door will close smoothly, seal effectively, and prevent issues such as water leakage, wind noise, and rattling. Secondly, precise measurements are necessary for meeting safety regulations. Auto doors need to be able to withstand certain forces during normal use and in the event of an accident. Any deviation in the door's dimensions can compromise its structural integrity and safety performance.

When measuring auto doors using a CMM, stability is of utmost importance. A stable door during measurement allows the CMM to capture accurate data points. If the door is not held firmly in place, vibrations or movements can occur, leading to inaccurate measurements. These inaccuracies can result in costly rework, production delays, and even product recalls.

How Auto Door CMM Holding Jigs Ensure Stability

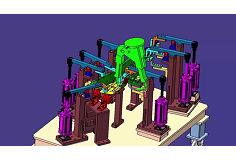

1. Customized Design

One of the key features of our auto door CMM holding jigs is their customized design. Each auto door has unique dimensions, shapes, and features. Our team of engineers works closely with automotive manufacturers to understand the specific requirements of their auto doors. We then design holding jigs that are tailored to fit the exact contours of the door. This customized fit ensures that the door is held securely in place during measurement.

For example, if an auto door has a complex curvature, our holding jig will be designed with corresponding curved surfaces to support the door evenly. This prevents any stress points or uneven pressure on the door, which could cause it to deform or move during measurement.

2. High - Quality Materials

We use high - quality materials in the construction of our auto door CMM holding jigs. Materials such as aluminum alloys and high - strength plastics are commonly used. These materials offer a combination of strength, durability, and light weight.

Aluminum alloys are known for their excellent strength - to - weight ratio. They can withstand the forces exerted during the measurement process without deforming. At the same time, their light weight makes the holding jigs easy to handle and install. High - strength plastics are also used in areas where a softer touch is required, such as in contact with the auto door's surface. These plastics prevent scratches or damage to the door while still providing a secure hold.

3. Precise Clamping Mechanisms

Our auto door CMM holding jigs are equipped with precise clamping mechanisms. These mechanisms are designed to apply the right amount of pressure to hold the door firmly in place without over - tightening. Over - tightening can cause the door to deform, while under - tightening can result in insufficient stability.

We use adjustable clamps that can be fine - tuned according to the specific requirements of the auto door. For example, some areas of the door may require more clamping force than others. Our adjustable clamps allow us to customize the clamping pressure at different points on the door, ensuring optimal stability.

4. Anti - Vibration Features

Vibrations can be a major source of measurement errors. To address this issue, our auto door CMM holding jigs are designed with anti - vibration features. We use damping materials and shock - absorbing components in the construction of the holding jigs.

These anti - vibration features help to reduce the impact of external vibrations, such as those caused by the movement of the CMM or other machinery in the manufacturing environment. By minimizing vibrations, we ensure that the auto door remains stable during measurement, allowing for more accurate data collection.

Real - World Applications and Benefits

In real - world automotive manufacturing, our auto door CMM holding jigs have proven to be highly effective. Many of our customers have reported significant improvements in measurement accuracy and production efficiency after using our products.

For instance, a major automotive manufacturer was experiencing issues with inaccurate door measurements, which were leading to high rejection rates. After implementing our auto door CMM holding jigs, the rejection rate was reduced by over 50%. This not only saved the manufacturer a significant amount of money in rework costs but also improved the overall quality of their vehicles.

Another benefit of using our holding jigs is the reduction in setup time. Our jigs are designed for easy installation and adjustment. This means that operators can quickly set up the holding jigs for each measurement, reducing downtime between measurements and increasing overall productivity.

Related Products and Solutions

In addition to auto door CMM holding jigs, we also offer a range of related products and solutions. Our Auto Door CMM Holding Fixture provides an alternative option for holding auto doors during measurement. These fixtures are designed to be highly versatile and can be used in different measurement setups.

We also have Door Parts CMM Holding Fixture for measuring individual door components, such as hinges, locks, and window regulators. These fixtures ensure the stability of the door parts during measurement, allowing for accurate data collection.

For automotive door parts manufacturers, our Gauges For Automotive Door Parts Manufacturer offer a comprehensive solution for quality control. These gauges are designed to measure the dimensions and tolerances of door parts with high precision.

Conclusion

Auto door CMM holding jigs are essential for ensuring the stability of auto doors during measurement. Our customized design, high - quality materials, precise clamping mechanisms, and anti - vibration features make our holding jigs a reliable choice for automotive manufacturers. By using our products, manufacturers can improve measurement accuracy, reduce production costs, and enhance the overall quality of their vehicles.

If you are in the automotive manufacturing industry and are looking for high - quality auto door CMM holding jigs or related products, we invite you to contact us for procurement and further discussion. We are committed to providing you with the best solutions to meet your specific needs.

References

- Automotive Manufacturing Handbook: This handbook provides in - depth knowledge about various manufacturing processes in the automotive industry, including measurement techniques and quality control.

- Journal of Precision Engineering: Articles in this journal often cover research on precision measurement and the use of holding jigs in manufacturing processes.

- Industry reports on automotive quality control: These reports offer insights into the latest trends and challenges in ensuring the quality of auto doors and other automotive components.