As a supplier of auto door CMM (Coordinate Measuring Machine) holding jigs, I've been constantly exploring the diverse applications of our products. One question that often arises in the automotive industry is whether an auto door CMM holding jig can be used for measuring the elasticity of auto door seals. In this blog, I'll delve into this topic, analyzing the feasibility, potential benefits, and limitations of using our auto door CMM holding jigs for such measurements.

Understanding Auto Door CMM Holding Jigs

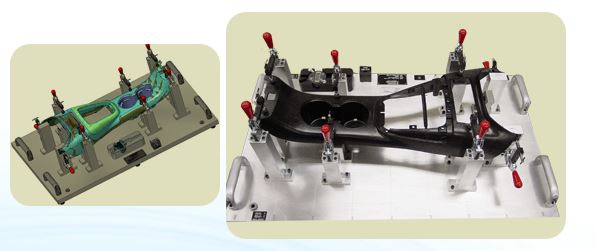

Auto door CMM holding jigs are precision tools designed to securely hold auto door components in place during the measurement process using a CMM. These jigs are crucial for ensuring accurate and repeatable measurements of various door parts, such as door panels, frames, and hinges. They are typically custom - designed to fit specific door models and can be made from a variety of materials, including aluminum, steel, and plastic.

Our company offers a wide range of auto door CMM holding jigs, including Door Parts CMM Holding Fixture, which is specifically tailored for measuring different door parts with high precision. We also provide Console Trim Bezels CMM Holding Fixture and Gauges For Automotive Door Parts Manufacturer, which are essential for the quality control of automotive interior and exterior door components.

The Importance of Measuring Auto Door Seal Elasticity

Auto door seals play a vital role in the overall performance of a vehicle. They are responsible for preventing water, dust, and noise from entering the vehicle cabin, as well as providing a proper seal to maintain the vehicle's climate control efficiency. The elasticity of the door seal is a critical factor that affects its sealing performance. If the seal is too stiff, it may not conform well to the door frame, leading to leaks. On the other hand, if the seal is too soft, it may not provide sufficient resistance to external forces, resulting in poor sealing.

Accurately measuring the elasticity of auto door seals is essential for ensuring their quality and performance. This measurement can help manufacturers identify any potential issues with the seal design or manufacturing process and make necessary adjustments to improve the seal's performance.

Feasibility of Using Auto Door CMM Holding Jigs for Measuring Seal Elasticity

The primary function of an auto door CMM holding jig is to hold the door component in a fixed position for dimensional measurement. However, with some modifications and additional equipment, it is possible to use these jigs for measuring the elasticity of auto door seals.

-

Positioning and Fixing the Seal

An auto door CMM holding jig can be used to position and fix the auto door seal in a specific orientation. By securely holding the seal in place, it ensures that the measurement is taken under consistent conditions. The jig can be designed to hold the seal in a way that mimics its actual installation on the door, which is crucial for obtaining accurate elasticity measurements. -

Combining with Force - Measuring Devices

To measure the elasticity of the seal, a force - measuring device, such as a load cell, can be integrated with the CMM holding jig. The load cell can be used to apply a controlled force to the seal, and the resulting deformation can be measured using the CMM. By analyzing the relationship between the applied force and the deformation, the elasticity of the seal can be determined. -

Data Acquisition and Analysis

The CMM can be used to collect data on the deformation of the seal during the force - application process. This data can then be analyzed using specialized software to calculate the elasticity modulus of the seal. The software can also be used to generate reports and graphs, which can provide valuable insights into the seal's elastic properties.

Potential Benefits of Using Auto Door CMM Holding Jigs for Seal Elasticity Measurement

-

High Precision

CMMs are known for their high precision in dimensional measurement. By using an auto door CMM holding jig for seal elasticity measurement, the same level of precision can be achieved. This is particularly important for automotive manufacturers who require accurate and reliable data for quality control and product development. -

Repeatability

The use of a CMM holding jig ensures that the measurement process is repeatable. Since the jig holds the seal in a consistent position and the force - application process is controlled, the same measurement conditions can be replicated for multiple samples. This allows for more accurate comparison of different seal designs or manufacturing batches. -

Efficiency

Integrating the seal elasticity measurement into the existing CMM measurement process can improve efficiency. Instead of using separate equipment for seal elasticity measurement, the CMM holding jig can be used to perform both dimensional and elasticity measurements in one setup. This reduces the time and cost associated with the measurement process.

Limitations and Challenges

-

Complexity of Seal Geometry

Auto door seals often have complex geometries, which can make it challenging to accurately measure their elasticity using a CMM holding jig. The seal may have different cross - sectional shapes and profiles, and the deformation behavior may vary depending on the location and direction of the applied force. Specialized fixtures and measurement techniques may be required to overcome these challenges. -

Material Properties

The material properties of the seal, such as its hardness and viscoelasticity, can also affect the accuracy of the elasticity measurement. Some seal materials may exhibit time - dependent behavior, which means that the deformation may continue to change even after the force is removed. This requires careful consideration when designing the measurement process and analyzing the data. -

Calibration and Standardization

To ensure the accuracy and reliability of the elasticity measurement, the CMM holding jig and the force - measuring device need to be properly calibrated. Additionally, there is a need for standardization of the measurement method and the interpretation of the results. Different manufacturers may have different requirements and specifications for seal elasticity, which can make it difficult to compare the results across different products.

Conclusion

In conclusion, while an auto door CMM holding jig is primarily designed for dimensional measurement of auto door components, it can be adapted for measuring the elasticity of auto door seals with some modifications and additional equipment. The use of a CMM holding jig for seal elasticity measurement offers several potential benefits, including high precision, repeatability, and efficiency. However, there are also some limitations and challenges that need to be addressed, such as the complexity of seal geometry, material properties, and calibration requirements.

If you are an automotive manufacturer or a supplier in the automotive industry and are interested in using our auto door CMM holding jigs for seal elasticity measurement or other applications, please feel free to contact us for more information. We are committed to providing high - quality products and solutions to meet your specific needs.

References

- Smith, J. (2018). Automotive Sealing Systems: Design, Materials, and Performance. CRC Press.

- Jones, A. (2019). Coordinate Measuring Machines: Principles and Applications. Springer.

- Brown, K. (2020). Elasticity and Viscoelasticity of Polymers. Wiley.