In the ever - evolving landscape of automotive manufacturing, the precision measurement of components is of paramount importance. Coordinate Measuring Machines (CMMs) play a crucial role in ensuring that auto parts meet the strict quality and dimensional accuracy requirements. Auto door CMM holding jigs are essential tools in this process, and in recent years, there have been several new technologies applied to enhance their functionality and performance. As a supplier of auto door CMM holding jigs, I am excited to share some insights into these technological advancements.

Advanced Materials

One of the significant technological trends in auto door CMM holding jigs is the use of advanced materials. Traditional jigs were often made from steel or aluminum, which have their limitations. Modern jigs are increasingly incorporating composite materials. These composites offer a high strength - to - weight ratio, which is beneficial in reducing the overall weight of the holding jig. A lighter jig is easier to handle during the setup and operation of the CMM, leading to increased efficiency in the manufacturing process.

For example, carbon fiber composites are being used in some high - end auto door CMM holding jigs. Carbon fiber has excellent stiffness and low thermal expansion properties. This means that the jig can maintain its shape and dimensional accuracy even under varying temperature conditions. In an automotive manufacturing environment, where temperature fluctuations can occur, this stability is crucial for accurate CMM measurements.

Intelligent Sensors

The integration of intelligent sensors is another major advancement in auto door CMM holding jigs. These sensors can provide real - time data about the position, orientation, and clamping force of the auto door within the jig. For instance, force - sensing resistors can be installed at the clamping points of the jig. These sensors can detect if the clamping force is within the optimal range. If the force is too low, the door may not be held securely, leading to inaccurate measurements. On the other hand, if the force is too high, it could potentially damage the door or the jig itself.

In addition to force sensors, there are also position sensors. These sensors can precisely determine the position of the auto door in the jig. They can detect any slight misalignments and send signals to the CMM control system. The control system can then adjust the measurement parameters accordingly to ensure accurate results. This real - time feedback loop significantly improves the measurement accuracy and reduces the chances of errors.

Automation and Robotics

Automation and robotics have revolutionized many aspects of the automotive industry, and auto door CMM holding jigs are no exception. Automated holding jigs can be programmed to perform repetitive tasks with high precision. For example, they can automatically load and unload auto doors onto the CMM. This not only saves time but also reduces the risk of human error.

Robotic arms can be integrated with the CMM holding jigs to perform more complex tasks. These robotic arms can adjust the position and orientation of the auto door in the jig based on the pre - programmed instructions. They can also perform additional tasks such as cleaning the door surface before measurement or applying protective coatings. This level of automation improves the overall efficiency of the CMM measurement process and allows for higher - volume production.

Modular Design

Modular design is a technology that has been gaining popularity in auto door CMM holding jigs. A modular jig consists of multiple interchangeable components. This design allows for greater flexibility in the manufacturing process. For example, if a different type of auto door needs to be measured, instead of replacing the entire jig, only the relevant modules need to be changed.

This modular approach also reduces the cost of tooling. Manufacturers do not need to invest in a completely new holding jig for each new door model. They can simply reconfigure the existing modules to suit the new requirements. Moreover, modular jigs are easier to maintain. If a particular module fails, it can be quickly replaced without disrupting the entire production line.

3D Printing Technology

3D printing has emerged as a game - changer in the manufacturing of auto door CMM holding jigs. This technology allows for the rapid prototyping of jigs. Instead of waiting weeks or months for a traditional machined jig to be produced, a 3D - printed jig can be ready in a matter of days.

3D printing also enables the production of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. For example, internal channels can be printed within the jig for the passage of cooling fluids or electrical wires. This can enhance the functionality of the jig and improve its performance.

In addition, 3D printing can use a variety of materials, including plastics and metals. This provides more options for the design and construction of the holding jig. For instance, plastic 3D - printed jigs are lightweight and cost - effective, making them suitable for low - volume production or prototyping.

Applications in Different Door Parts

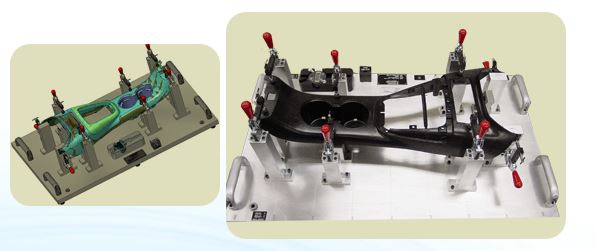

These new technologies are not only applicable to the overall auto door CMM holding jigs but also to specific door parts. For example, Console Trim Bezels CMM Holding Fixture can benefit from the use of advanced materials and intelligent sensors. The bezel needs to be held precisely during measurement to ensure its proper fit and finish in the auto door.

Similarly, Auto Door CMM Holding Fixture takes full advantage of the new technologies. The fixture can use automation and robotics to handle the large and heavy auto doors efficiently. And Door Parts CMM Holding Fixture can utilize 3D printing to quickly produce custom - designed fixtures for different door components.

Conclusion

The application of new technologies in modern auto door CMM holding jigs has brought about significant improvements in the automotive manufacturing process. From advanced materials and intelligent sensors to automation, modular design, and 3D printing, these technologies have enhanced the accuracy, efficiency, and flexibility of the CMM measurement process.

As a supplier of auto door CMM holding jigs, I am committed to staying at the forefront of these technological advancements. We continuously invest in research and development to incorporate the latest technologies into our products. Our goal is to provide our customers with high - quality, innovative holding jigs that meet their specific needs.

If you are in the automotive manufacturing industry and are looking for reliable auto door CMM holding jigs, we would love to have a discussion with you. Whether you need a standard jig or a custom - designed solution, our team of experts can work with you to find the best fit for your production requirements. Contact us to start a procurement discussion and take your automotive manufacturing process to the next level.

References

- Smith, J. (2020). Advanced Materials in Automotive Manufacturing. Journal of Automotive Technology, 15(2), 123 - 135.

- Johnson, M. (2021). Intelligent Sensors for Precision Manufacturing. Manufacturing Review, 22(3), 89 - 98.

- Brown, A. (2019). Automation and Robotics in the Automotive Industry. Automotive Engineering Journal, 18(4), 201 - 210.

- Wilson, S. (2022). 3D Printing in Tooling Design. Tooling Technology Magazine, 25(1), 45 - 53.