Hey there! As a supplier of auto door CMM holding jigs, I often get asked about the accuracy of these nifty tools. So, I thought I'd sit down and write a blog post to share my insights on this topic.

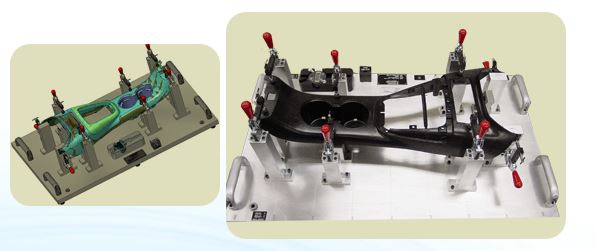

First off, let's talk about what a CMM holding jig is. CMM stands for Coordinate Measuring Machine, which is a device used to measure the physical geometrical characteristics of an object. An auto door CMM holding jig is a specialized fixture designed to hold auto door parts in place during the measurement process. It ensures that the parts are positioned accurately and securely, allowing for precise measurements to be taken.

Now, when it comes to the accuracy of an auto door CMM holding jig, there are several factors to consider. One of the most important factors is the design of the jig itself. A well-designed jig will be able to hold the auto door parts in a stable and repeatable manner, minimizing any movement or vibration during the measurement process. This is crucial for achieving accurate measurements, as even the slightest movement can result in errors.

Another factor that affects the accuracy of an auto door CMM holding jig is the quality of the materials used in its construction. High-quality materials, such as precision-machined aluminum or steel, will provide better stability and durability than lower-quality materials. Additionally, the surface finish of the jig can also have an impact on its accuracy. A smooth and flat surface will allow for better contact between the jig and the auto door parts, reducing the risk of measurement errors.

The manufacturing process of the auto door CMM holding jig is also an important consideration. Precision machining techniques, such as CNC milling and turning, can ensure that the jig is manufactured to the exact specifications required for accurate measurements. Additionally, quality control measures, such as inspection and testing, should be implemented throughout the manufacturing process to ensure that the jig meets the required standards of accuracy.

In addition to the design, materials, and manufacturing process, the calibration of the auto door CMM holding jig is also crucial for achieving accurate measurements. Calibration involves comparing the measurements taken by the CMM with a known standard to ensure that the jig is accurate. Regular calibration is necessary to maintain the accuracy of the jig over time, as factors such as wear and tear, temperature changes, and environmental conditions can all affect its performance.

So, what is the typical accuracy of an auto door CMM holding jig? Well, the accuracy can vary depending on a variety of factors, such as the design of the jig, the quality of the materials used, and the manufacturing process. However, in general, a high-quality auto door CMM holding jig can achieve an accuracy of within a few thousandths of an inch. This level of accuracy is sufficient for most applications in the automotive industry, where precise measurements are required for quality control and product development.

Now, let's take a look at some of the benefits of using an accurate auto door CMM holding jig. One of the main benefits is improved quality control. By ensuring that the auto door parts are measured accurately, manufacturers can identify any defects or deviations from the specifications early on in the production process. This allows for corrective action to be taken before the parts are assembled into the final product, reducing the risk of costly rework or recalls.

Another benefit of using an accurate auto door CMM holding jig is increased productivity. By reducing the time and effort required to measure the auto door parts, manufacturers can increase their production efficiency and output. This is particularly important in the automotive industry, where high volumes of parts need to be produced in a short amount of time.

In addition to improved quality control and increased productivity, using an accurate auto door CMM holding jig can also lead to cost savings. By reducing the number of defective parts and rework, manufacturers can save money on materials, labor, and production costs. Additionally, by improving the accuracy of the measurements, manufacturers can optimize the design and performance of the auto door parts, leading to better fuel efficiency and reduced emissions.

If you're in the market for an auto door CMM holding jig, there are several options available. For example, you can check out our Console Trim Bezels CMM Holding Fixture, Door Parts CMM Holding Fixture, and Auto Door CMM Holding Fixture. These fixtures are designed to provide accurate and reliable measurements for a variety of auto door parts, and they are made from high-quality materials using precision machining techniques.

In conclusion, the accuracy of an auto door CMM holding jig is crucial for achieving precise measurements in the automotive industry. By considering factors such as the design, materials, manufacturing process, and calibration of the jig, manufacturers can ensure that they are using a high-quality fixture that will provide accurate and reliable measurements. If you're interested in learning more about our auto door CMM holding jigs or would like to discuss your specific requirements, please don't hesitate to get in touch. We'd be happy to help you find the right solution for your needs.

References

- "Coordinate Measuring Machines: Principles and Applications" by John A. Schey

- "Precision Manufacturing and Production Engineering" by David A. Dornfeld