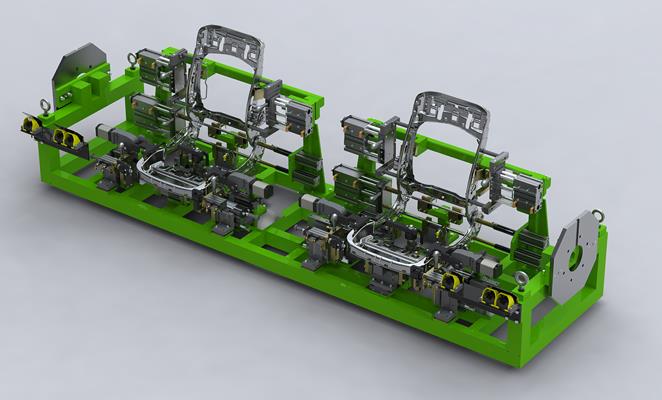

Hey there! As a supplier of rear seats welding jigs, I've been in the thick of the industry for quite a while. And let me tell you, the price of these jigs isn't set in stone. There are a bunch of factors that come into play, and I'm gonna break them down for you.

1. Material Quality

First off, the materials used to make rear seats welding jigs have a huge impact on the price. We've got a few options here. High - grade steel is a popular choice. It's strong, durable, and can withstand the high - pressure and high - heat conditions that come with the welding process. But, it's also more expensive. You see, the quality of the steel matters. Steel with better corrosion resistance and higher tensile strength will cost more, but it'll also last longer and require less maintenance.

On the other hand, we've got some suppliers using lower - grade materials to cut costs. While the initial price might seem attractive, these jigs are likely to wear out faster, leading to more frequent replacements. As a supplier, I believe in using the best materials because I want my customers to get their money's worth. After all, a high - quality rear seats welding jig is an investment.

2. Design Complexity

The design of the welding jig is another big factor. If the rear seats have a simple design, the welding jig won't need to be overly complicated. It'll have fewer components and a more straightforward structure, which means lower production costs and a lower price for the customer.

However, when the rear seats have a complex design, like those with unique shapes, multiple layers, or special features, the welding jig has to be more sophisticated. We need to use advanced CAD/CAM technology to design it, and it might require more precise machining and assembly. For example, if the rear seats have an irregular curve, the jig has to be designed to hold the parts in the exact position for accurate welding. This kind of complexity adds to the production time and cost, and that's reflected in the price.

3. Precision Requirements

Precision is key in the welding process. The higher the precision requirements, the more expensive the rear seats welding jig will be. In the automotive industry, even a tiny deviation can lead to problems with the final product. So, if the customer requires a high - precision welding jig, we need to use more advanced manufacturing techniques and high - accuracy measuring equipment.

For instance, some high - end cars demand extremely precise welding for their rear seats to ensure a perfect fit and finish. To meet these requirements, we might use CNC machining, which is more accurate but also more costly than traditional machining methods. We also need to perform rigorous quality control checks to make sure the jig meets the specified precision standards. All these extra steps and equipment drive up the price.

4. Production Volume

The volume of rear seats welding jigs ordered by the customer can significantly affect the price. When a customer orders a large quantity, we can take advantage of economies of scale. We can buy materials in bulk, which usually comes with a discount. The production process becomes more efficient as well, because we can set up the production line for continuous manufacturing. This reduces the per - unit production cost, and we can offer a lower price to the customer.

Conversely, if the order volume is small, the production cost per unit goes up. We can't benefit from bulk purchasing, and the setup time for production becomes a larger proportion of the overall cost. So, small - volume orders generally have a higher price per jig.

5. Customization

Many customers have specific requirements for their rear seats welding jigs. Customization can range from simple modifications to a completely unique design. If a customer wants a customized welding jig, it'll cost more.

Customization means we have to spend extra time on design and development. We might need to conduct additional research and testing to ensure the jig meets the customer's needs. For example, if a customer wants a welding jig with a special clamping mechanism or a specific color, we have to make adjustments to our standard production process. All these custom - made features add to the cost and, ultimately, the price of the jig.

6. Market Competition

The level of competition in the market also plays a role in the price of rear seats welding jigs. In a highly competitive market, suppliers are constantly trying to attract customers by offering lower prices or better value - added services. We might see some suppliers slashing prices to gain market share.

However, as a responsible supplier, I believe in maintaining a balance between price and quality. While I understand the pressure to be competitive, I won't compromise on the quality of my products. I focus on providing excellent customer service, reliable products, and technical support to differentiate myself from the competition.

7. Labor Costs

Labor costs are an important part of the overall production cost. In regions where labor is expensive, the price of rear seats welding jigs will be higher. Skilled workers are needed to design, manufacture, and assemble these jigs. They require specialized knowledge and experience, and they expect to be compensated accordingly.

In addition, the cost of training and retaining these workers also adds to the overall cost. If a supplier has to invest a lot in training its workforce to keep up with the latest manufacturing techniques, that cost will be passed on to the customer.

8. Technology and Innovation

The use of new technologies and innovative solutions can affect the price of rear seats welding jigs. For example, the integration of smart sensors in the welding jig can provide real - time data on the welding process, such as temperature, pressure, and welding quality. This kind of technology can improve the efficiency and accuracy of the welding process, but it also adds to the cost.

New manufacturing processes, like 3D printing, are also being explored in the production of welding jigs. While 3D printing can offer some advantages, such as faster prototyping and the ability to create complex shapes, it can be more expensive than traditional manufacturing methods, at least for now.

As a supplier, I'm always looking for ways to incorporate new technologies to improve my products. But I also understand that customers have different budgets, so I try to offer a range of options to meet their needs.

In conclusion, there are many factors that affect the price of rear seats welding jigs. As a supplier, I'm committed to providing high - quality products at a fair price. I understand that each customer has unique requirements, and I'm willing to work with them to find the best solution. Whether you're looking for a simple, cost - effective welding jig or a highly customized, high - precision one, I've got you covered.

If you're in the market for rear seats welding jigs, or if you have any questions about the factors affecting the price, don't hesitate to reach out. Let's have a chat and see how we can work together to meet your needs. You can also check out our other products like Automotive Seat Welding Fixture, Front Bumper Welding Fixture, and Car Stamping Parts checking fixture.

References

- "Automotive Manufacturing Technology" - A comprehensive book on the latest manufacturing techniques in the automotive industry.

- Industry reports on the welding jig market, which provide insights into market trends and cost factors.