Maintaining an auto door CMM holding jig is crucial for ensuring accurate measurements and long - term performance. As a supplier of auto door CMM holding jigs, I've seen firsthand how proper maintenance can save time, money, and headaches down the line. In this blog, I'll share some tips on how to keep your auto door CMM holding jig in top - notch condition.

Understanding the Auto Door CMM Holding Jig

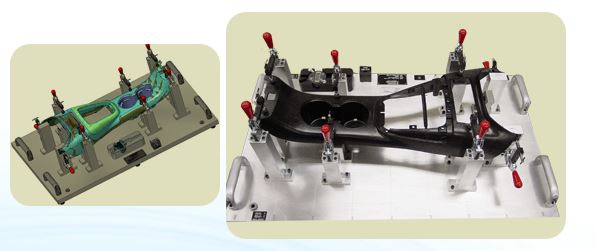

Before we dive into maintenance, let's quickly talk about what an auto door CMM (Coordinate Measuring Machine) holding jig is. It's a specialized tool used to hold auto door parts securely in place during the measurement process. This allows for precise and consistent measurements of the door components, which is essential for quality control in the automotive industry. You can find more details about auto door CMM holding jigs at Auto Door CMM Holding Fixture.

Regular Cleaning

The first and most basic step in maintaining your auto door CMM holding jig is regular cleaning. Over time, dust, debris, and even small metal shavings can accumulate on the jig. This buildup can interfere with the accuracy of the measurements and also cause premature wear and tear on the components.

To clean the jig, start by using a soft - bristle brush to gently remove any loose debris. You can use a compressed air gun to blow out any hard - to - reach areas. For stubborn dirt or grease, a mild cleaning solution can be used. Make sure to follow the manufacturer's instructions when using any cleaning agents, as some chemicals can damage the surface of the jig. After cleaning, dry the jig thoroughly to prevent rust or corrosion.

Inspection for Wear and Tear

Regular inspections are key to catching any issues with your auto door CMM holding jig before they become major problems. Look for signs of wear on the contact points, such as scratches, dents, or excessive wear patterns. These areas are crucial for holding the auto door parts accurately, and any damage can lead to inaccurate measurements.

Check the clamping mechanisms as well. Make sure the clamps are still functioning properly and can hold the door parts firmly in place. If you notice any loose or damaged parts in the clamping system, they should be replaced immediately. Also, inspect the alignment pins and holes. Misaligned pins can cause errors in the measurement process, so it's important to ensure they are in good condition.

Lubrication

Proper lubrication is essential for the smooth operation of your auto door CMM holding jig. Lubricating the moving parts, such as the clamping mechanisms and hinges, reduces friction and wear. This not only extends the lifespan of the jig but also ensures that it functions accurately.

Use a high - quality lubricant that is suitable for the materials used in the jig. Apply the lubricant sparingly to the appropriate areas, following the manufacturer's guidelines. Over - lubrication can attract dust and debris, which can cause more problems in the long run.

Calibration

Calibration is perhaps the most important aspect of maintaining an auto door CMM holding jig. Calibration ensures that the jig is providing accurate measurements. It should be calibrated regularly, depending on the frequency of use and the manufacturer's recommendations.

During calibration, a known standard is used to check the accuracy of the jig. If any discrepancies are found, adjustments can be made to bring the jig back into proper alignment. Calibration should be performed by a trained professional to ensure accurate results. You can also refer to Gauges For Automotive Door Parts Manufacturer for more information on calibration and related tools.

Storage

Proper storage of the auto door CMM holding jig is also important for its maintenance. When not in use, the jig should be stored in a clean, dry environment. Avoid storing it in areas where it can be exposed to moisture, extreme temperatures, or physical damage.

If possible, use a dedicated storage rack or cabinet to keep the jig organized and protected. Cover the jig with a protective cover to prevent dust and debris from accumulating on it during storage.

Training for Operators

Another important factor in maintaining an auto door CMM holding jig is ensuring that the operators are properly trained. Operators should know how to handle the jig correctly, including how to clean, inspect, and lubricate it. They should also be aware of the importance of calibration and how to recognize signs of wear and tear.

Providing regular training sessions can help operators stay up - to - date on the best practices for maintaining the jig. This can lead to fewer errors and a longer lifespan for the jig.

Documentation

Keeping detailed documentation of the maintenance activities is a good practice. Record the dates of cleaning, inspections, lubrication, and calibration. This documentation can be useful for tracking the history of the jig, identifying any recurring issues, and demonstrating compliance with quality control standards.

Special Considerations for Different Types of Jigs

There are different types of auto door CMM holding jigs, and each may have its own specific maintenance requirements. For example, a jig used for console trim bezels may have different contact points and clamping mechanisms compared to a standard auto door jig. You can learn more about console trim bezels CMM holding fixtures at Console Trim Bezels CMM Holding Fixture.

Make sure to understand the unique features of your particular jig and follow the appropriate maintenance procedures. Some jigs may be made of different materials, such as plastic or metal, and these materials may require different cleaning and lubrication methods.

Conclusion

Maintaining an auto door CMM holding jig is a multi - faceted process that involves regular cleaning, inspection, lubrication, calibration, proper storage, operator training, and documentation. By following these steps, you can ensure that your jig provides accurate measurements for a long time, which is essential for quality control in the automotive industry.

If you're in the market for a high - quality auto door CMM holding jig or need more information on maintenance, feel free to reach out. We're here to help you with all your auto door CMM holding jig needs. Whether you're a small - scale automotive parts manufacturer or a large - scale production facility, we can provide the right solutions for you.

References

- General knowledge of automotive manufacturing and quality control.

- Experience as a supplier of auto door CMM holding jigs.