Ensuring compliance with safety regulations when using a rear seats welding jig is of utmost importance in the automotive manufacturing industry. As a rear seats welding jig supplier, we understand the critical role that these jigs play in the production process and the need for strict adherence to safety standards. In this blog post, we will discuss some key steps and best practices to ensure the safe and compliant use of rear seats welding jigs.

Understanding Safety Regulations

Before delving into the specific measures for ensuring compliance, it is essential to have a clear understanding of the relevant safety regulations. These regulations can vary depending on the region and the nature of the manufacturing process. In general, they cover aspects such as equipment safety, operator training, and workplace safety.

For example, in many countries, there are regulations regarding the design and construction of welding jigs to prevent electrical hazards, mechanical failures, and fire risks. These regulations often specify requirements for materials, electrical insulation, and safety guards. Additionally, there are regulations related to operator training, which mandate that operators must be properly trained and certified to use welding equipment and jigs.

Design and Manufacturing of Safe Rear Seats Welding Jigs

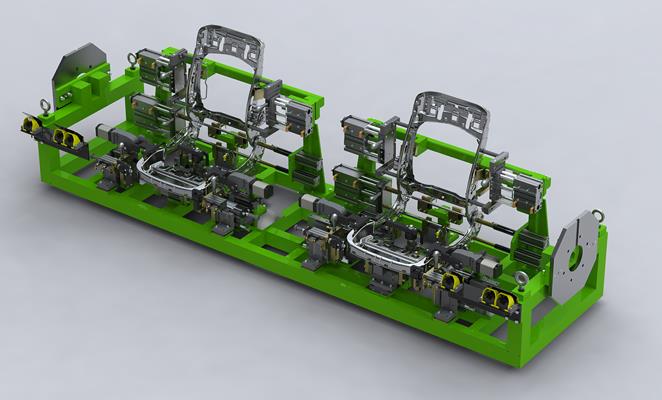

As a supplier, we take great care in the design and manufacturing of our rear seats welding jigs to ensure compliance with safety regulations. Our design process involves a thorough risk assessment to identify potential hazards and implement appropriate safety features.

- Material Selection: We use high-quality materials that are suitable for the welding process and can withstand the stresses and strains of continuous use. These materials are also chosen for their electrical insulation properties to prevent electrical shocks.

- Safety Guards and Enclosures: Our welding jigs are equipped with safety guards and enclosures to protect operators from flying sparks, hot metal, and other hazards. These guards are designed to be easily removable for maintenance and cleaning but are securely fastened during operation.

- Electrical Safety: We ensure that all electrical components of our welding jigs are properly insulated and grounded to prevent electrical fires and shocks. We also install safety switches and emergency stop buttons to allow operators to quickly shut down the equipment in case of an emergency.

Operator Training and Certification

Proper operator training is crucial for ensuring the safe and compliant use of rear seats welding jigs. We provide comprehensive training programs for our customers' operators to ensure that they have the necessary knowledge and skills to operate the equipment safely.

- Initial Training: Our initial training program covers the basic principles of welding, the operation of the rear seats welding jig, and safety procedures. Operators are trained on how to set up the equipment, adjust the welding parameters, and perform routine maintenance.

- Certification: After completing the initial training, operators are required to pass a certification exam to demonstrate their proficiency in operating the welding jig safely. This certification is valid for a specific period and must be renewed periodically.

- Ongoing Training: We also offer ongoing training programs to keep operators up-to-date with the latest safety regulations and best practices. These training programs may include refresher courses, safety seminars, and on-site training.

Workplace Safety Measures

In addition to the design of the welding jig and operator training, workplace safety measures are also essential for ensuring compliance with safety regulations. These measures include:

- Ventilation: Welding produces fumes and gases that can be harmful to operators' health. Therefore, it is important to have proper ventilation systems in place to remove these fumes and gases from the workplace.

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, such as welding helmets, gloves, and protective clothing, to protect themselves from the hazards associated with welding.

- Housekeeping: A clean and organized workplace is essential for preventing accidents and injuries. Regular cleaning and maintenance of the welding area, including the removal of debris and waste, can help to reduce the risk of slips, trips, and falls.

Regular Inspection and Maintenance

Regular inspection and maintenance of rear seats welding jigs are essential for ensuring their safe and reliable operation. We recommend that our customers establish a regular inspection and maintenance schedule to identify and address any potential issues before they become major problems.

- Pre-Operational Checks: Operators should perform pre-operational checks on the welding jig before each use to ensure that it is in good working condition. These checks may include inspecting the electrical connections, safety guards, and welding electrodes.

- Periodic Inspections: In addition to pre-operational checks, periodic inspections should be conducted by a qualified technician to assess the overall condition of the welding jig. These inspections may include testing the electrical components, checking the alignment of the jig, and inspecting the welding joints.

- Maintenance and Repairs: Any issues identified during the inspection should be addressed immediately to prevent further damage to the welding jig. Regular maintenance, such as lubrication and calibration, can also help to extend the lifespan of the equipment.

Conclusion

Ensuring compliance with safety regulations when using a rear seats welding jig is a shared responsibility between the supplier, the operator, and the employer. By following the steps and best practices outlined in this blog post, you can help to ensure the safe and reliable operation of your rear seats welding jig and protect the health and safety of your operators.

If you are interested in purchasing a rear seats welding jig or have any questions about our products and services, please feel free to contact us. We are committed to providing our customers with high-quality welding jigs that meet the highest safety standards. You can also explore our other products such as Car Stamping Parts checking fixture, Automotive Seat Welding Fixture, and Front Bumper Welding Fixture.

References

- Occupational Safety and Health Administration (OSHA). (n.d.). Welding, Cutting, and Brazing. Retrieved from [OSHA website]

- American Welding Society (AWS). (n.d.). Safety in Welding, Cutting, and Allied Processes. Retrieved from [AWS website]

- International Organization for Standardization (ISO). (n.d.). ISO 14113:2019 - Welding and allied processes - Health and safety - Requirements for welding and allied processes. Retrieved from [ISO website]