The cost of an auto door CMM (Coordinate Measuring Machine) holding jig can vary significantly based on multiple factors. As a seasoned supplier of auto door CMM holding jigs, I've witnessed firsthand the wide range of prices in the market and understand the elements that contribute to these variations.

Factors Influencing the Cost

Design Complexity

One of the primary determinants of the cost is the design complexity of the holding jig. A simple, straightforward design that holds a standard auto door part with minimal adjustments or customizations will generally be less expensive. For instance, if the auto door part has a regular shape and requires only basic clamping mechanisms to secure it on the CMM, the manufacturing process is relatively uncomplicated.

On the other hand, a complex design might involve intricate geometries to accommodate unique door part shapes, multiple adjustable components to ensure precise positioning, and advanced features such as quick - change systems. These additional design elements increase the time and effort required for engineering and development, as well as the cost of materials and manufacturing. For example, some high - end auto door CMM holding jigs are designed to hold multiple door parts simultaneously, which requires a more elaborate structure and precise alignment mechanisms. This type of complex design can cost significantly more than a basic jig.

Material Selection

The materials used in the construction of the auto door CMM holding jig also play a crucial role in determining its cost. Common materials include aluminum, steel, and various plastics. Aluminum is a popular choice due to its lightweight nature, corrosion resistance, and relatively low cost. It is suitable for most general - purpose auto door CMM holding jigs. However, if high strength and durability are required, steel may be used. Steel jigs can withstand heavier loads and more rigorous use, but they are also heavier and more expensive than aluminum jigs.

In some cases, high - performance plastics are used, especially when weight reduction and electrical insulation are important factors. These plastics can be engineered to have specific properties such as high stiffness and low thermal expansion. However, they are often more expensive than traditional metals. For example, a holding jig made from a specialized engineering plastic for a high - end automotive application can cost two to three times more than an aluminum equivalent.

Precision Requirements

The level of precision required for the auto door CMM holding jig is another significant cost factor. CMMs are used to measure parts with extremely high accuracy, and the holding jig must be able to hold the door part in a stable and precise position during the measurement process. Higher precision requirements mean tighter tolerances in manufacturing, which demand more advanced machining techniques and quality control measures.

For example, if the holding jig needs to position the door part within a tolerance of ±0.01 mm, the manufacturing process will be much more challenging and time - consuming compared to a jig with a tolerance of ±0.1 mm. This increased precision often requires the use of high - end machining equipment and skilled operators, which drives up the cost of production.

Quantity of Production

The quantity of auto door CMM holding jigs ordered also affects the cost per unit. When a large quantity is ordered, economies of scale come into play. The fixed costs associated with design, tooling, and setup can be spread over a larger number of units, resulting in a lower cost per piece.

For example, if a customer orders 100 auto door CMM holding jigs, the cost per unit may be 20% lower than if they order only 10 units. This is because the cost of creating the necessary molds, fixtures, and programming for the manufacturing process is divided among more units. However, it's important to note that there may be a limit to the economies of scale, as very large production runs may require additional resources and management, which can start to increase the cost again.

Cost Range in the Market

Based on my experience as a supplier, the cost of an auto door CMM holding jig can range from a few hundred dollars to several thousand dollars. A basic, single - part holding jig made from aluminum with a relatively low precision requirement may cost around $300 - $800. These jigs are often used for simple automotive applications where the door parts have standard shapes and the measurement accuracy requirements are not extremely high.

For medium - complexity jigs, which may have adjustable components, more precise positioning features, and be made from a combination of materials, the cost can range from $800 - $2500. These jigs are suitable for a wide range of automotive door part measurement applications in both mass - production and custom - built vehicles.

High - end, complex auto door CMM holding jigs with advanced features such as multi - part holding capabilities, quick - change systems, and extremely high precision can cost upwards of $2500. These jigs are typically used in high - tech automotive manufacturing facilities where the highest level of accuracy and efficiency is required.

Our Company's Offerings

As a supplier of auto door CMM holding jigs, we offer a wide range of products to meet different customer needs and budgets. We understand that every automotive manufacturer has unique requirements, and we work closely with our customers to design and manufacture the most suitable holding jigs.

Our product portfolio includes Gauges For Automotive Door Parts Manufacturer, which are designed to provide accurate measurement and inspection of automotive door parts. These gauges are available in various designs and materials to ensure optimal performance.

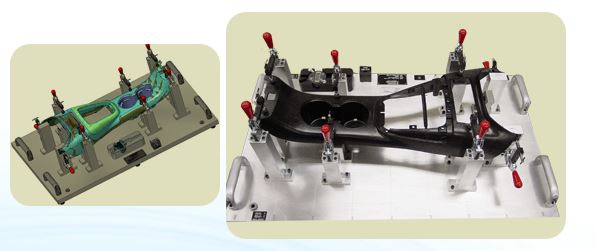

We also offer Door Parts CMM Holding Fixture, which are specifically tailored to hold door parts securely during the CMM measurement process. Our door parts holding fixtures are engineered to meet high - precision requirements and can be customized according to the specific dimensions and shapes of the door parts.

In addition, our Console Trim Bezels CMM Holding Fixture are designed to hold console trim bezels accurately for measurement. These fixtures are made with high - quality materials and advanced manufacturing techniques to ensure long - term reliability.

Conclusion

The cost of an auto door CMM holding jig is influenced by a variety of factors, including design complexity, material selection, precision requirements, and production quantity. Understanding these factors can help automotive manufacturers make informed decisions when purchasing holding jigs. At our company, we are committed to providing high - quality auto door CMM holding jigs at competitive prices. Whether you are looking for a basic, cost - effective solution or a high - end, precision - engineered jig, we have the expertise and resources to meet your needs.

If you are interested in our auto door CMM holding jigs or would like to discuss your specific requirements, please feel free to contact us. We look forward to the opportunity to work with you and provide you with the best solutions for your automotive measurement needs.

References

- Automotive Manufacturing Handbook, 2nd Edition

- Precision Engineering Journal: Research on Coordinate Measuring Machine Fixtures

- Materials Science for Automotive Applications, 3rd Edition