In the highly competitive automotive industry, the quality control of auto doors is of paramount importance. Auto doors not only play a crucial role in the safety and functionality of vehicles but also significantly impact the overall aesthetics and user experience. As a leading supplier of auto door CMM (Coordinate Measuring Machine) holding jigs, I have witnessed firsthand how these innovative tools can revolutionize the quality control process in auto door production. In this blog post, I will delve into the ways in which an auto door CMM holding jig improves the efficiency of quality control, highlighting its benefits and real - world applications.

Understanding the Role of CMM in Auto Door Production

Before discussing the auto door CMM holding jig, it is essential to understand the role of the Coordinate Measuring Machine in auto door production. CMM is a precision measuring device that can accurately measure the geometric characteristics of a part, such as dimensions, shapes, and positions. In the context of auto door production, CMM is used to ensure that the doors meet the strict design specifications. This includes checking the alignment of the door frame, the fit of the door panels, and the accuracy of the hinges and locks.

However, to obtain accurate measurements using a CMM, the auto door needs to be held securely and precisely in place. This is where the auto door CMM holding jig comes into play.

How Auto Door CMM Holding Jigs Improve Efficiency

Precise Positioning

One of the primary functions of an auto door CMM holding jig is to provide precise positioning of the auto door during the measurement process. These jigs are custom - designed to match the specific geometry of the auto door, ensuring that the door is held in the exact position required for accurate CMM measurements. By eliminating any potential movement or misalignment of the door, the holding jig reduces measurement errors and improves the reliability of the quality control process.

For example, when measuring the alignment of the door frame, a well - designed holding jig will hold the door in a stable position, allowing the CMM to accurately measure the angles and dimensions. This precision positioning ensures that any deviations from the design specifications can be quickly identified and corrected, saving time and resources in the production process.

Reduced Setup Time

Traditional methods of holding auto doors for CMM measurements often involve complex and time - consuming setup procedures. Workers may need to use multiple clamps and fixtures to secure the door, which can be a labor - intensive and error - prone process. Auto door CMM holding jigs, on the other hand, are designed for quick and easy setup.

These jigs are typically equipped with features such as quick - release mechanisms and adjustable fixtures, allowing workers to mount and dismount the auto door from the holding jig in a matter of minutes. This significantly reduces the setup time between measurements, increasing the overall throughput of the quality control process. For instance, in a high - volume auto door production line, the time saved from reduced setup can translate into a substantial increase in the number of doors that can be inspected per day.

Standardization of Measurement

Auto door CMM holding jigs provide a standardized way of holding the auto doors for measurement. This means that regardless of who is operating the CMM or when the measurement is taken, the door will be held in the same position and orientation. Standardization is crucial for ensuring the consistency and comparability of measurement results.

When all measurements are taken under the same conditions, it becomes easier to identify trends and patterns in the quality data. This allows manufacturers to make more informed decisions about process improvements and quality control strategies. For example, if a particular batch of auto doors shows a consistent deviation in a certain dimension, the standardized measurement data obtained using the holding jig can help pinpoint the root cause of the problem, whether it is an issue with the manufacturing equipment or the raw materials.

Compatibility with Different Door Designs

The automotive industry is constantly evolving, with new auto door designs being introduced regularly. An effective auto door CMM holding jig is designed to be flexible and adaptable to different door designs. Our company offers a range of holding jigs that can be customized to accommodate various types of auto doors, including different sizes, shapes, and configurations.

This flexibility is essential for manufacturers who produce multiple models of vehicles or who need to adapt to changing market demands. Instead of investing in multiple sets of holding fixtures for different door designs, a single, adaptable holding jig can be used, reducing the cost and complexity of the quality control process.

Real - World Applications

Large - Scale Auto Door Manufacturing Plants

In large - scale auto door manufacturing plants, where high - volume production is the norm, the efficiency gains provided by auto door CMM holding jigs are particularly significant. These plants often have multiple production lines and a high demand for quality control. By using CMM holding jigs, they can increase the speed and accuracy of the quality inspection process, ensuring that a large number of auto doors are produced to the required standards in a short period.

For example, a major automotive manufacturer may produce thousands of auto doors per day. With the help of auto door CMM holding jigs, they can quickly and accurately measure each door, reducing the time spent on quality control and increasing the overall production efficiency.

Small and Medium - Sized Enterprises (SMEs)

Even for small and medium - sized enterprises in the auto door manufacturing sector, auto door CMM holding jigs can offer significant benefits. SMEs often have limited resources and may not have the luxury of a large quality control department. By using these holding jigs, they can improve the accuracy of their quality control process without investing in expensive and complex measurement equipment.

The reduced setup time and improved measurement accuracy provided by the holding jigs allow SMEs to compete more effectively in the market by ensuring that their products meet the same high - quality standards as larger manufacturers.

Related Products and Their Significance

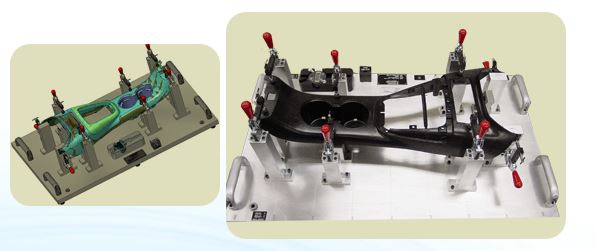

In addition to auto door CMM holding jigs, there are other related products that play important roles in the quality control of auto parts. For example, the Door Parts CMM Holding Fixture is used to hold individual door parts, such as door handles and window regulators, during the CMM measurement process. This ensures the accurate measurement of these small but crucial components.

The Console Trim Bezels CMM Holding Fixture is another important product. Console trim bezels are part of the interior design of the vehicle, and their accurate measurement is essential for a seamless fit and finish.

Moreover, the Gauges For Automotive Door Parts Manufacturer are used to quickly check the basic dimensions of automotive door parts, providing an additional layer of quality control.

Conclusion and Call to Action

In conclusion, auto door CMM holding jigs are indispensable tools in the quality control process of auto door production. They improve efficiency by providing precise positioning, reducing setup time, standardizing measurements, and offering compatibility with different door designs. Whether you are a large - scale automotive manufacturer or a small - to - medium - sized enterprise, investing in high - quality auto door CMM holding jigs can significantly enhance the quality and productivity of your auto door production.

If you are in the auto door manufacturing industry and are looking to improve your quality control efficiency, we invite you to contact us to discuss your specific needs. Our team of experts can provide you with customized solutions and high - quality auto door CMM holding jigs.

References

- Automotive Manufacturing Technology Handbook.

- Precision Measurement in the Automotive Industry: Best Practices and Case Studies.