Hey there! As a supplier of auto door CMM holding jigs, I've seen firsthand how these nifty tools can make a huge difference in reducing production waste. In this blog, I'll break down the ins and outs of how auto door CMM holding jigs contribute to a more efficient and waste - free production process.

1. Understanding Auto Door CMM Holding Jigs

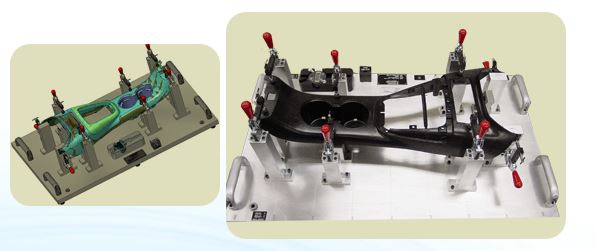

First off, let's get on the same page about what an auto door CMM (Coordinate Measuring Machine) holding jig is. It's a specialized fixture designed to securely hold auto door components in place during the measurement process using a CMM. This ensures that the components are positioned accurately, allowing for precise measurements of their dimensions and geometries.

When you're manufacturing auto doors, getting the measurements right is crucial. Even a tiny deviation can lead to parts that don't fit together properly, which means they'll end up as waste. That's where our Auto Door CMM Holding Fixture comes in. It provides a stable and repeatable setup for each measurement, so you can be confident that you're getting accurate data every time.

2. Reducing Measurement Errors

One of the main ways auto door CMM holding jigs reduce production waste is by minimizing measurement errors. Without a proper holding jig, it's easy for auto door components to shift or move during the measurement process. This can result in inaccurate readings, which in turn can lead to incorrect manufacturing decisions.

For example, if a measurement shows that a door panel is within tolerance when it's actually not because of a shifting issue, the panel might be assembled into a door. Later on, during the final quality check, it could be found that the door doesn't fit correctly, and the whole assembly has to be scrapped.

Our holding jigs are designed with precision in mind. They use high - quality materials and advanced engineering techniques to keep the auto door components firmly in place. This reduces the likelihood of movement and ensures that the CMM can take accurate measurements. By getting the measurements right the first time, manufacturers can avoid producing parts that don't meet the required specifications, thus reducing waste.

3. Improving Process Efficiency

Another benefit of using auto door CMM holding jigs is that they improve process efficiency. When components are held securely in place, the measurement process is faster and more streamlined. Operators don't have to spend time repositioning the parts or dealing with measurement inconsistencies.

Let's say you're measuring a batch of auto door hinges. Without a holding jig, you might have to adjust each hinge multiple times to get a proper measurement. This not only takes up a lot of time but also increases the chances of errors. With our Door Parts CMM Holding Fixture, the hinges can be quickly and easily placed in the correct position, and the measurement can be taken right away.

This increased efficiency means that more parts can be measured in less time. As a result, the production process can move along more smoothly, and there's less chance of bottlenecks. When the production process is efficient, there's less likelihood of over - production or the production of parts that are no longer needed due to delays, which helps in reducing waste.

4. Ensuring Consistency

Consistency is key in the auto manufacturing industry. Every auto door produced should be of the same high quality and meet the same specifications. Auto door CMM holding jigs play a vital role in ensuring this consistency.

Since the holding jigs provide a standardized way of holding the components, each measurement is taken under the same conditions. This means that the data collected is consistent across different parts and batches. For instance, if you're manufacturing a series of auto door handles, using a holding jig ensures that each handle is measured in the exact same way.

When there's consistency in measurement, manufacturers can make more informed decisions about the production process. They can set accurate tolerances and adjust the manufacturing parameters as needed. This helps in producing parts that are more likely to meet the quality standards, reducing the number of defective parts and ultimately cutting down on waste.

5. Enabling Early Detection of Issues

Auto door CMM holding jigs also allow for early detection of potential issues in the production process. By taking accurate and consistent measurements, manufacturers can identify trends or anomalies in the component dimensions.

For example, if the measurements of a particular type of auto door window frame start to show a gradual deviation from the specifications, it could be a sign of a problem with the manufacturing equipment or the raw materials. With the help of the holding jig, these issues can be detected early on, before a large number of defective parts are produced.

Manufacturers can then take corrective actions, such as adjusting the equipment or changing the raw materials. This proactive approach helps in preventing the production of a large amount of waste and saves both time and money.

6. Customization for Different Components

Not all auto door components are the same. There are various shapes, sizes, and materials involved in the manufacturing of auto doors. Our auto door CMM holding jigs can be customized to fit different types of components.

Whether it's a complex Console Trim Bezels CMM Holding Fixture or a simple door latch, we can design a holding jig that meets the specific requirements of the component. This customization ensures that each component is held securely and measured accurately, regardless of its unique characteristics.

By having a holding jig that is tailored to the component, manufacturers can further improve the accuracy of the measurements and reduce the risk of waste. It also means that the holding jig can be used effectively in different stages of the production process, from prototyping to mass production.

Conclusion

In conclusion, auto door CMM holding jigs are essential tools for reducing production waste in the auto manufacturing industry. They reduce measurement errors, improve process efficiency, ensure consistency, enable early detection of issues, and can be customized for different components.

If you're in the auto manufacturing business and looking to cut down on production waste, I highly recommend considering our auto door CMM holding jigs. They're designed to meet the highest standards of quality and precision, and they can make a significant difference in your production process.

If you're interested in learning more about our products or discussing your specific needs, don't hesitate to reach out. We're always happy to have a chat and see how we can help you optimize your production process and reduce waste.

References

- Automotive Manufacturing Handbook

- Precision Measurement in the Auto Industry: Best Practices