In the automotive manufacturing industry, the quality and precision of auto door components are of utmost importance. Coordinate Measuring Machines (CMMs) play a crucial role in ensuring that these components meet the required specifications. However, the effectiveness of CMM measurements heavily relies on the use of appropriate holding jigs. As a leading supplier of auto door CMM holding jigs, I have witnessed firsthand how these jigs can significantly impact the measurement accuracy of different auto door components.

The Role of Auto Door CMM Holding Jigs

Auto door CMM holding jigs are specialized fixtures designed to securely hold auto door components in place during the measurement process. They provide a stable and repeatable platform for the CMM to accurately measure the dimensions, shapes, and positions of the components. Without a proper holding jig, the components may move or shift during measurement, leading to inaccurate results.

The primary function of an auto door CMM holding jig is to eliminate any potential sources of error caused by component movement. By firmly securing the component, the jig ensures that the CMM can take precise measurements without interference. This is particularly important when measuring complex or irregularly shaped components, where even the slightest movement can result in significant measurement errors.

Factors Affecting Measurement Accuracy

Several factors can influence the measurement accuracy of auto door components when using a CMM holding jig. Understanding these factors is essential for selecting the right jig and optimizing the measurement process.

1. Jig Design and Construction

The design and construction of the holding jig are critical to its performance. A well-designed jig should provide a secure and stable grip on the component while minimizing any distortion or deformation. It should also be easy to install and remove, allowing for efficient measurement operations.

The material used in the construction of the jig is another important consideration. High-quality materials, such as aluminum or steel, offer better rigidity and stability, reducing the risk of component movement. Additionally, the surface finish of the jig should be smooth and free of any imperfections to ensure accurate contact with the component.

2. Component Fixturing

Proper fixturing of the component is essential for accurate measurement. The jig should be designed to hold the component in the correct position and orientation, ensuring that the CMM can access all the necessary measurement points. This may involve using locators, clamps, or other fixtures to secure the component firmly in place.

It is also important to consider the shape and size of the component when designing the holding jig. Different components may require different fixturing methods to ensure optimal measurement accuracy. For example, a large and heavy component may require a more robust jig with additional support, while a small and delicate component may require a more gentle fixturing method to avoid damage.

3. Jig Calibration

Regular calibration of the holding jig is necessary to maintain its accuracy. Over time, the jig may experience wear and tear, which can affect its performance. Calibration ensures that the jig is still providing a consistent and accurate grip on the component, allowing for reliable measurement results.

Calibration should be performed using a certified calibration device and following the manufacturer's recommended procedures. It is also important to document the calibration results and keep a record of the calibration history for traceability purposes.

4. Environmental Conditions

The environmental conditions in which the measurement is performed can also impact the accuracy of the results. Temperature, humidity, and vibration can all affect the performance of the CMM and the holding jig. For example, changes in temperature can cause the component and the jig to expand or contract, leading to measurement errors.

To minimize the effects of environmental conditions, it is important to perform measurements in a controlled environment. This may involve using temperature and humidity control systems or isolating the measurement area from external vibrations.

Impact on Different Auto Door Components

The measurement accuracy of different auto door components can be affected differently by the use of a CMM holding jig. Here are some examples of how the jig can impact the measurement of specific components:

1. Door Panels

Door panels are one of the largest and most complex components of an auto door. They are typically made of sheet metal or plastic and have a variety of shapes and contours. The accuracy of door panel measurements is crucial for ensuring proper fit and alignment with other door components.

A well-designed CMM holding jig for door panels should provide a secure and stable grip on the panel while allowing the CMM to access all the necessary measurement points. The jig should also be designed to minimize any distortion or deformation of the panel, ensuring accurate measurement of its dimensions and shape.

2. Window Regulators

Window regulators are responsible for controlling the movement of the window glass in the auto door. They are typically made of metal or plastic and have a complex mechanism. The accuracy of window regulator measurements is important for ensuring smooth and reliable operation of the window.

A CMM holding jig for window regulators should be designed to hold the regulator in the correct position and orientation while allowing the CMM to measure its various components, such as the gears, pulleys, and cables. The jig should also be designed to minimize any movement or vibration of the regulator during measurement, ensuring accurate results.

3. Locking Mechanisms

Locking mechanisms are used to secure the auto door in the closed position. They are typically made of metal or plastic and have a variety of shapes and sizes. The accuracy of locking mechanism measurements is important for ensuring proper operation and security of the door.

A CMM holding jig for locking mechanisms should provide a secure and stable grip on the mechanism while allowing the CMM to measure its various components, such as the locks, latches, and keys. The jig should also be designed to minimize any movement or vibration of the mechanism during measurement, ensuring accurate results.

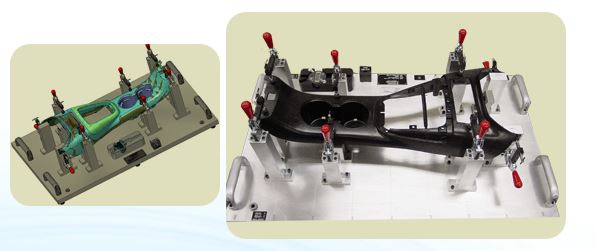

4. Console Trim Bezels

Console trim bezels are decorative components that are used to enhance the appearance of the auto door. They are typically made of plastic or metal and have a variety of shapes and finishes. The accuracy of console trim bezel measurements is important for ensuring proper fit and alignment with other door components.

A CMM holding jig for console trim bezels should provide a secure and stable grip on the bezel while allowing the CMM to measure its dimensions and shape. The jig should also be designed to minimize any distortion or deformation of the bezel, ensuring accurate measurement of its surface finish and contours.

Conclusion

In conclusion, the use of a high-quality Auto Door CMM Holding Fixture is essential for ensuring the measurement accuracy of different auto door components. By providing a secure and stable platform for the CMM, the jig eliminates any potential sources of error caused by component movement, allowing for precise and reliable measurement results.

When selecting a CMM holding jig for auto door components, it is important to consider factors such as jig design and construction, component fixturing, jig calibration, and environmental conditions. By choosing the right jig and optimizing the measurement process, manufacturers can ensure the quality and precision of their auto door components, leading to improved product performance and customer satisfaction.

If you are in the market for a high-quality Door Parts CMM Holding Fixture, please feel free to contact us. Our team of experts can help you select the right jig for your specific application and provide you with the support and guidance you need to optimize your measurement process.

References

- ISO 10360-2:2009 - Geometrical product specifications (GPS) — Acceptance and reverification tests for coordinate measuring machines (CMM) — Part 2: CMMs used for measuring linear dimensions

- ASME B89.4.1-2006 - Performance Evaluation of Coordinate Measuring Machines

- VDI/VDE 2617 - Guidelines for the Performance Evaluation of Coordinate Measuring Machines