In the realm of precision manufacturing, checking fixtures play a pivotal role in ensuring the quality and accuracy of various components. As a supplier of Checking Fixtures China, I often encounter inquiries about the upgrading services offered by Chinese checking fixture manufacturers. In this blog post, I will delve into this topic, exploring the capabilities, benefits, and considerations of upgrading services provided by Chinese manufacturers.

The Landscape of Chinese Checking Fixture Manufacturing

China has emerged as a global powerhouse in the manufacturing industry, and the checking fixture sector is no exception. With advanced technology, skilled labor, and a cost - effective production model, Chinese manufacturers have been able to offer high - quality checking fixtures to a wide range of industries, including automotive, aerospace, and consumer electronics.

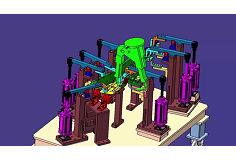

Many Chinese checking fixture manufacturers have made significant investments in research and development, adopting the latest manufacturing techniques such as CNC machining, 3D printing, and laser scanning. These technologies not only enable the production of highly accurate and complex checking fixtures but also facilitate the implementation of upgrading services.

Upgrading Services Offered by Chinese Manufacturers

1. Technological Upgrades

One of the primary reasons for upgrading checking fixtures is to incorporate the latest technological advancements. Chinese manufacturers are well - equipped to offer such upgrades. For example, they can retrofit existing checking fixtures with advanced sensors. These sensors can provide real - time data on the dimensions, tolerances, and surface quality of the parts being inspected. This data can be transmitted to a central system for analysis, enabling more efficient quality control processes.

Moreover, with the development of digital twin technology, Chinese manufacturers can create virtual replicas of the checking fixtures. This allows for remote monitoring, predictive maintenance, and simulation of different inspection scenarios. By upgrading to a digital twin - enabled checking fixture, manufacturers can significantly improve the accuracy and efficiency of their quality control operations.

2. Design Improvements

Over time, the design requirements of checking fixtures may change due to new product designs, updated industry standards, or evolving customer needs. Chinese checking fixture manufacturers are capable of conducting design reviews and making necessary improvements to existing fixtures.

They can optimize the fixture's structure to reduce its weight, improve its rigidity, and enhance its ease of use. For instance, by using lightweight yet strong materials such as carbon fiber composites, the handling of the checking fixture can be made more convenient. Additionally, manufacturers can redesign the fixture's clamping mechanisms to ensure more secure and precise positioning of the parts being inspected.

3. Compatibility Upgrades

As new production lines are introduced or existing ones are modified, checking fixtures may need to be upgraded to be compatible with the new equipment. Chinese manufacturers can modify the dimensions, interfaces, and mounting points of the checking fixtures to ensure seamless integration with the new production environment.

For example, if a company upgrades its CNC machining centers, the checking fixtures may need to be adjusted to fit the new workholding systems. Chinese manufacturers can carry out these modifications quickly and cost - effectively, minimizing the downtime of the production line.

Benefits of Upgrading Services

1. Cost - Effectiveness

Upgrading existing checking fixtures is often more cost - effective than purchasing new ones. Chinese manufacturers can offer competitive pricing for their upgrading services due to their efficient production processes and access to a wide range of raw materials. By choosing to upgrade, companies can save a significant amount of capital while still achieving the desired improvements in quality control.

2. Reduced Downtime

When upgrading checking fixtures, Chinese manufacturers can often complete the work in a relatively short period. This is because they have the necessary expertise and resources to quickly diagnose the issues and implement the upgrades. As a result, the downtime of the production line can be minimized, ensuring continuous production and timely delivery of products.

3. Enhanced Product Quality

Upgraded checking fixtures can provide more accurate and reliable inspection results. This directly translates into improved product quality. By detecting defects and deviations earlier in the production process, companies can take corrective actions promptly, reducing the number of defective products and improving customer satisfaction.

Considerations When Choosing Upgrading Services

1. Manufacturer's Expertise

It is crucial to choose a Chinese checking fixture manufacturer with extensive experience and expertise in upgrading services. A manufacturer with a proven track record in the industry is more likely to understand the specific requirements of different industries and provide high - quality upgrading solutions.

2. Communication and Support

Effective communication is essential during the upgrading process. The manufacturer should be able to communicate clearly with the customer, understand their needs, and provide regular updates on the progress of the upgrade. Additionally, they should offer after - sales support to ensure that the upgraded checking fixture operates smoothly.

3. Quality Assurance

Before finalizing the upgrade, it is important to ensure that the manufacturer has a strict quality assurance system in place. This includes rigorous testing and calibration procedures to guarantee that the upgraded checking fixture meets the required accuracy and performance standards.

Our Company's Capabilities

As a supplier of Sunyuu Gauges And Checking Fixtures, we have a team of experienced engineers and technicians who are well - versed in upgrading checking fixtures. We offer a comprehensive range of upgrading services, including technological upgrades, design improvements, and compatibility upgrades.

Our Checking Fixtures CMM Holding Fixtures And Gauges are known for their high quality and reliability. We use the latest manufacturing technologies and adhere to strict quality control standards. Whether you need to upgrade your existing checking fixtures to incorporate advanced sensors or to improve their design for better usability, we can provide customized solutions to meet your specific needs.

Moreover, as a Stamping Checking Fixture Manufacturer Supplier, we understand the unique requirements of the stamping industry. We can upgrade stamping checking fixtures to ensure accurate inspection of stamped parts, taking into account factors such as material thickness, surface finish, and shape complexity.

Conclusion

In conclusion, Chinese checking fixture manufacturers do offer comprehensive upgrading services. These services can bring significant benefits in terms of cost - effectiveness, reduced downtime, and enhanced product quality. When considering upgrading your checking fixtures, it is important to choose a reliable manufacturer with the necessary expertise and resources.

If you are interested in upgrading your checking fixtures or have any questions about our services, please feel free to contact us. We are committed to providing you with the best upgrading solutions to meet your quality control needs.

References

Smith, J. (2020). Advancements in Checking Fixture Technology. Manufacturing Technology Journal, 15(2), 45 - 52.

Lee, K. (2021). The Role of Digital Twin in Quality Control for Checking Fixtures. Industrial Engineering Review, 22(3), 67 - 74.

Chen, L. (2019). Design Optimization of Checking Fixtures for Improved Efficiency. Journal of Precision Engineering, 12(4), 33 - 40.