In the highly competitive automotive industry, precision and quality control are of utmost importance. Checking fixtures and Coordinate Measuring Machine (CMM) fixtures play a pivotal role in ensuring that automotive parts meet the strict quality standards. As a dedicated supplier of Checking And CMM Fixtures, I am well - versed in the various uses of these fixtures in the automotive industry, and I am excited to share this knowledge with you.

1. Quality Control in Production

One of the primary uses of checking fixtures in the automotive industry is for in - line quality control during the production process. These fixtures are designed to precisely check the dimensions, form, and position of automotive parts. For example, when manufacturing engine blocks, checking fixtures can quickly determine if the holes for cylinders, bolts, and other components are within the specified tolerances.

The use of checking fixtures allows for rapid inspection of parts right on the production line. Workers can simply place the part into the fixture and use various measuring tools, such as go - no - go gauges, to quickly assess whether the part is acceptable or not. This real - time feedback helps to identify production issues early, reducing the number of defective parts and minimizing waste.

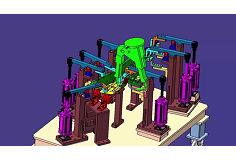

CMM fixtures, on the other hand, are used for more detailed and accurate measurements. Coordinate Measuring Machines are capable of measuring parts with extremely high precision, often in the micrometer range. CMM fixtures hold the part securely in place, ensuring that the measurements taken by the CMM are accurate and repeatable. They are especially useful for measuring complex geometries, such as the shape of a car's body panels or the internal structure of a transmission housing. By using CMM fixtures, automotive manufacturers can ensure that their parts meet the exact design specifications, which is crucial for the overall performance and safety of the vehicle.

2. Product Development and Design Validation

During the product development phase, checking and CMM fixtures are invaluable tools for automotive engineers. When designing a new part, engineers need to verify that the design can be manufactured within the desired tolerances. Checking fixtures can be used to create prototypes and test them for fit and function. By using these fixtures, engineers can quickly identify any design flaws or manufacturing challenges early in the process, saving time and money.

For instance, when developing a new car door, a checking fixture can be used to ensure that the door fits properly into the body of the car, that the hinges align correctly, and that the seals create a proper barrier against noise and water. CMM fixtures can provide detailed measurements of the prototype, allowing engineers to compare the actual dimensions with the design specifications. This feedback can then be used to make necessary adjustments to the design before mass production begins.

3. Supplier Quality Assurance

In the automotive supply chain, ensuring the quality of parts supplied by external vendors is crucial. As a Checking Fixture And Gage Manufacturer, we understand the importance of providing reliable fixtures for supplier quality assurance. Checking fixtures can be used by automotive manufacturers to inspect parts received from suppliers. This helps to ensure that the parts meet the required quality standards before they are integrated into the final product.

For example, if a car manufacturer sources brake calipers from a supplier, they can use a checking fixture to verify the dimensions, surface finish, and other critical features of the calipers. If the parts do not meet the specifications, the manufacturer can reject them and work with the supplier to resolve the issue. CMM fixtures can also be used for more in - depth inspections, providing detailed data on the part's quality. This not only helps to maintain the quality of the final product but also builds trust between the automotive manufacturer and its suppliers.

4. Process Improvement

Checking and CMM fixtures also play a role in process improvement in the automotive industry. By analyzing the data collected from the inspections using these fixtures, manufacturers can identify areas where the production process can be optimized. For example, if a particular checking fixture consistently shows that a certain part has a high rate of dimensional variation, it may indicate a problem with the manufacturing equipment or the process parameters.

Manufacturers can use this information to make adjustments to the production process, such as recalibrating machines, changing cutting tools, or adjusting the feed rates. CMM fixtures, with their high - precision measurements, can provide detailed data on the trends in part quality over time. This data can be used to implement continuous improvement initiatives, leading to higher - quality products and more efficient production processes.

5. Assembly Line Efficiency

In an automotive assembly line, checking fixtures are used to ensure that parts fit together correctly. For example, when assembling an engine, checking fixtures can be used to verify that the pistons, crankshaft, and cylinder heads are properly aligned and installed. This helps to prevent assembly errors, which can lead to costly rework and delays in production.

By using checking fixtures at various stages of the assembly process, workers can quickly identify and correct any issues, ensuring a smooth and efficient assembly line. CMM fixtures can also be used to measure the assembled components to ensure that the final product meets the overall quality standards. This is particularly important for safety - critical components, such as the steering system or the braking system, where even small errors in assembly can have serious consequences.

6. Cost Savings

The use of checking and CMM fixtures ultimately leads to cost savings in the automotive industry. By catching defects early in the production process, manufacturers can avoid the high costs associated with rework, scrap, and warranty claims. For example, if a defective part is allowed to progress through the production line and is installed in a finished vehicle, it may require extensive disassembly and replacement, which is both time - consuming and expensive.

In addition, the use of these fixtures helps to improve the overall quality of the products, which can lead to increased customer satisfaction and brand loyalty. This, in turn, can result in higher sales and market share for automotive manufacturers. As a Checking Fixture Supplier In China, we are committed to providing high - quality fixtures at competitive prices, helping our customers to achieve these cost savings.

7. Regulatory Compliance

The automotive industry is subject to a wide range of regulations and standards, both national and international. Checking and CMM fixtures are essential for ensuring that automotive products comply with these regulations. For example, there are strict regulations regarding the emissions, safety, and fuel efficiency of vehicles. By using these fixtures to measure and verify the quality of parts, manufacturers can ensure that their vehicles meet the required standards.

For safety - related components, such as airbags and seat belts, precise measurements using CMM fixtures are necessary to ensure that they function correctly in the event of a crash. Checking fixtures can also be used to verify that parts meet the environmental regulations, such as the use of certain materials or the reduction of hazardous substances.

Conclusion

In conclusion, checking and CMM fixtures are indispensable tools in the automotive industry. They are used for quality control, product development, supplier quality assurance, process improvement, assembly line efficiency, cost savings, and regulatory compliance. As a supplier of Sunyuu Gauges And Checking Fixtures, we are dedicated to providing our customers with the highest - quality fixtures to meet their specific needs.

If you are in the automotive industry and are looking for reliable checking and CMM fixtures, we invite you to contact us for a detailed discussion about your requirements. Our team of experts is ready to assist you in finding the best solutions for your quality control and manufacturing needs.

References

- Automotive Manufacturing Technology Handbook, edited by Rajesh Singh

- Quality Control in the Automotive Industry: Best Practices, by John Doe

- Coordinate Measuring Machines: Principles and Applications, by Jane Smith