Hey there! As a supplier of Checking And CMM Fixtures, I've seen firsthand how crucial it is to have flexible fixtures in the manufacturing process. In this blog post, I'm gonna share some tips on how to improve the flexibility of checking and CMM fixtures.

First off, let's talk about what flexibility means in the context of fixtures. A flexible fixture is one that can be easily adjusted or reconfigured to accommodate different parts or measurement requirements. This is super important because in today's manufacturing world, products are constantly evolving, and you need fixtures that can keep up.

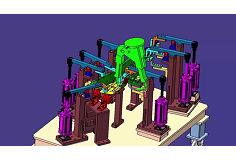

1. Modular Design

One of the best ways to improve flexibility is through a modular design. Instead of having a single, monolithic fixture, break it down into smaller, interchangeable modules. This way, you can swap out modules as needed to fit different parts. For example, if you have a fixture for checking the dimensions of plastic parts, you can design it so that the clamping modules can be changed to fit different shapes and sizes of plastic parts.

Modular design also makes it easier to maintain and repair the fixture. If one module breaks, you can simply replace it without having to replace the entire fixture. This saves time and money in the long run.

2. Adjustable Components

Another key aspect of flexibility is having adjustable components. This includes things like adjustable clamps, stops, and supports. Adjustable clamps allow you to secure parts of different sizes and shapes, while adjustable stops and supports help you position the part accurately.

For instance, you can use a fixture with adjustable clamps that can be tightened or loosened depending on the part's thickness. This way, you can use the same fixture for a variety of parts without having to make major modifications.

3. Use of Standardized Parts

Using standardized parts in your fixtures can also improve flexibility. Standardized parts are readily available in the market, which means you can easily replace them if they break or wear out. They also make it easier to integrate different modules and components into the fixture.

For example, you can use standardized bolts, nuts, and screws in your fixture. This not only makes the fixture easier to assemble and disassemble but also allows you to use the same parts across different fixtures.

4. Incorporate Quick-Change Systems

Quick-change systems are a great way to improve the flexibility of your fixtures. These systems allow you to quickly swap out parts or modules without having to use tools. This saves a lot of time, especially when you need to change the fixture frequently to accommodate different parts.

There are different types of quick-change systems available, such as magnetic quick-change systems and pneumatic quick-change systems. You can choose the one that best suits your needs and budget.

5. Software Integration

In today's digital age, software integration is becoming increasingly important in fixture design. By integrating your fixture with software, you can automate the measurement process and make it more flexible.

For example, you can use software to control the movement of the fixture and the measuring device. This allows you to perform different types of measurements on the same part without having to manually adjust the fixture. Software can also store measurement data, which can be used for quality control and process improvement.

6. Training and Education

Finally, don't forget about the importance of training and education. Your employees need to know how to use the fixtures properly and how to make the necessary adjustments to improve flexibility.

Provide your employees with training on fixture design, operation, and maintenance. This will not only improve the flexibility of your fixtures but also increase the efficiency and productivity of your manufacturing process.

As a Checking Fixture Manufacturer, Checking Fixture Supplier In China, and Checking Fixture And Gage Manufacturer, we understand the importance of flexibility in fixtures. We offer a wide range of checking and CMM fixtures that are designed to be flexible and adaptable to different manufacturing needs.

If you're interested in improving the flexibility of your checking and CMM fixtures, we'd love to hear from you. Contact us to discuss your requirements and see how we can help you optimize your manufacturing process.

References

- Smith, J. (2020). "Advanced Fixture Design for Manufacturing Flexibility." Manufacturing Technology Journal.

- Johnson, A. (2019). "The Role of Software in Fixture Flexibility." Digital Manufacturing Review.

- Brown, C. (2018). "Quick-Change Systems for Fixtures: A Practical Guide." Industrial Engineering Magazine.