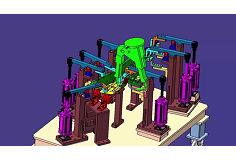

As a supplier of rear seats welding jigs, I understand the importance of ensuring these fixtures have a long lifespan. A rear seats welding jig is a crucial tool in the automotive manufacturing process, and its durability directly impacts production efficiency and cost - effectiveness. In this blog, I'll share some practical strategies on how to extend the lifespan of a rear seats welding jig.

1. Proper Installation and Setup

The first step in extending the lifespan of a rear seats welding jig is to ensure its proper installation and setup. When installing the jig, it must be placed on a stable and level surface. Any unevenness can cause stress concentration on certain parts of the jig during the welding process, leading to premature wear and deformation.

Before use, carefully calibrate the jig according to the manufacturer's instructions. This includes checking the alignment of all components, such as clamping devices and positioning pins. Incorrect calibration can result in inaccurate welding, which not only affects the quality of the welded rear seats but also puts additional stress on the jig itself. For example, if the clamping force is not evenly distributed, some parts of the jig may experience excessive pressure, leading to cracks or breakage over time.

2. Regular Cleaning and Maintenance

Regular cleaning is essential for the longevity of a rear seats welding jig. During the welding process, spatter, dust, and other debris can accumulate on the surface of the jig. This debris can interfere with the proper functioning of the jig's moving parts, such as slides and hinges, and can also cause corrosion if left unattended.

Use appropriate cleaning agents and tools to remove the debris. For example, a soft - bristle brush can be used to gently clean the surface, and a mild solvent can be applied to dissolve stubborn spatter. After cleaning, make sure to dry the jig thoroughly to prevent rust.

In addition to cleaning, regular maintenance of the jig's mechanical components is also necessary. Lubricate moving parts, such as bearings and slides, at regular intervals to reduce friction and wear. Check for loose bolts and nuts and tighten them as needed. Replace worn - out parts promptly to prevent further damage to the jig.

3. Optimal Welding Parameters

Selecting the right welding parameters is crucial for the lifespan of the rear seats welding jig. Welding parameters such as current, voltage, and welding speed can significantly affect the heat input and stress distribution on the jig.

If the welding current is too high, it can generate excessive heat, which may cause thermal deformation of the jig. On the other hand, if the current is too low, the welding quality may be compromised, and additional re - work may be required, which also puts extra stress on the jig. Similarly, an inappropriate welding speed can lead to uneven heat distribution and poor weld quality.

Work closely with your welding engineers to optimize the welding parameters based on the material of the rear seats and the design of the jig. Conduct regular tests and adjustments to ensure that the welding process is as efficient and gentle on the jig as possible.

4. Operator Training

Well - trained operators play a vital role in extending the lifespan of a rear seats welding jig. Operators should be familiar with the proper operation and handling of the jig. They should know how to load and unload the rear seats correctly to avoid unnecessary impacts on the jig.

Provide comprehensive training to operators on the jig's features, functions, and safety precautions. Train them to recognize early signs of wear and damage, such as unusual noises or vibrations during operation. Encourage operators to report any issues immediately so that they can be addressed promptly.

5. Storage Conditions

Proper storage conditions are also important when the rear seats welding jig is not in use. Store the jig in a dry and clean environment to prevent corrosion. If possible, cover the jig with a protective sheet to prevent dust and debris from accumulating on it.

When storing the jig for an extended period, make sure to release any clamping forces and move all moving parts to their neutral positions. This helps to relieve stress on the components and prevent deformation.

6. Inspection and Monitoring

Regular inspection and monitoring of the rear seats welding jig are essential for detecting potential problems early. Establish a routine inspection schedule to check for signs of wear, damage, or misalignment. Use non - destructive testing methods, such as ultrasonic testing or visual inspection, to detect internal cracks or defects.

Implement a monitoring system to track the performance of the jig over time. This can include recording data such as the number of welding cycles, the temperature during welding, and any maintenance activities. Analyzing this data can help you identify trends and predict when parts may need to be replaced or when maintenance should be performed.

Related Products

If you are also interested in other types of welding fixtures, we offer a wide range of products. For example, our Front Bumper Welding Fixture is designed to ensure precise welding of front bumpers. Our Automotive Seat Welding Fixture is specifically tailored for the welding of automotive seats, providing high - quality and efficient welding solutions. Additionally, our Car Stamping Parts checking fixture can be used to check the accuracy of car stamping parts.

Conclusion

Extending the lifespan of a rear seats welding jig requires a comprehensive approach that includes proper installation, regular cleaning and maintenance, optimal welding parameters, operator training, proper storage, and inspection and monitoring. By implementing these strategies, you can not only reduce the cost of replacing jigs but also improve the overall efficiency and quality of your welding operations.

If you are in the market for high - quality rear seats welding jigs or have any questions about extending the lifespan of your existing jigs, we are here to help. Contact us to start a procurement discussion and find the best solutions for your automotive manufacturing needs.

References

- ASM Handbook Committee. (2008). ASM Handbook, Volume 6: Welding, Brazing, and Soldering. ASM International.

- American Welding Society. (2017). AWS D1. 1/D1. 1M:2017 Structural Welding Code - Steel. American Welding Society.

- Tooling and Manufacturing Association. (2015). Tooling and Manufacturing Handbook. Society of Manufacturing Engineers.