Showroom

Customized Copper Braid Wire 660kVA Cutting and Invterter Welding Machine

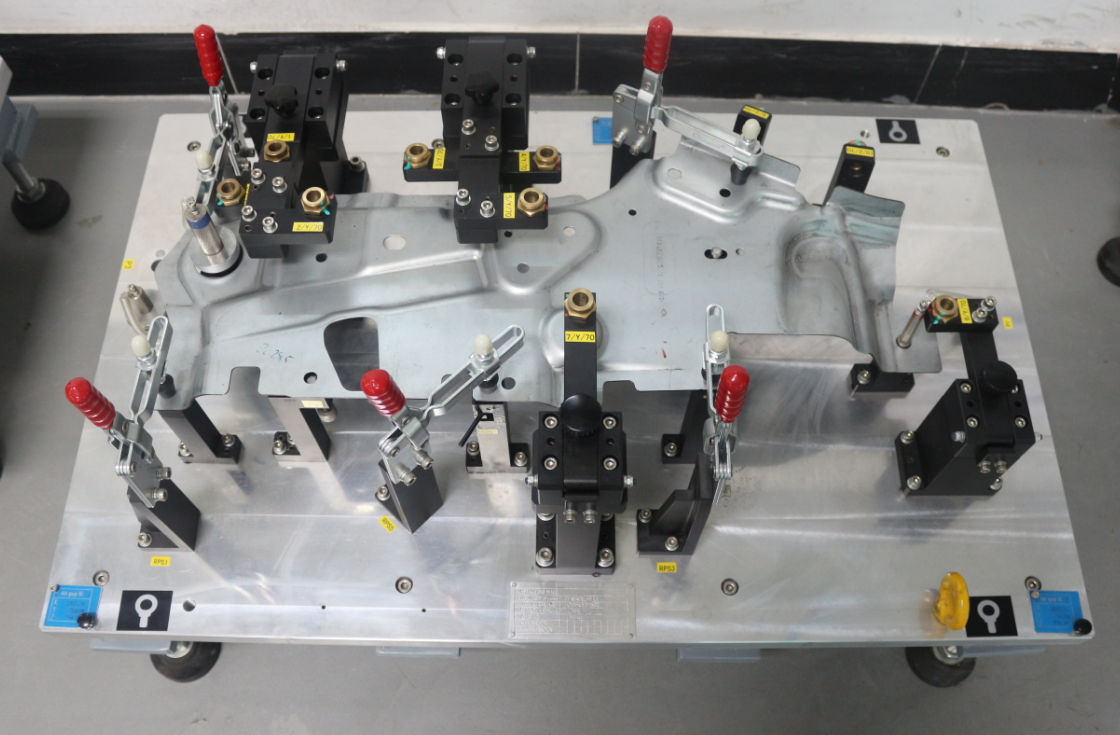

With industry-leading technical strength, experienced technical team, and honesty-based service attitude, we provide our customers with effective and professional quality services to create first-class brand in the Auto Bumper Checking Fixture, Auto assembly stamping parts checking fixture, IP Assembly Parts Checking Fixture manufacturers China industry. We are committed to building harmonious labor relations, allowing the company to develop continuously and healthily, so that employees and the company can grow together. In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit. We will inherit and promote our entrepreneurial spirit and effectively fulfill our economic, political and social responsibilities.

If you are going to check the quotation of robotic welding fixture line made in China from one of the famous arc-welding robot workstation, spot welding robot workstation manufacturers and suppliers in China, It is always at your service.

1. Design and manufacture for Robotic Welding Fixture Line

2. All Design 100% according to customer requirement.

3. Supply OEM Service

4. Material:steel/Aluminium

5. ISO 9001:2015 Certificate

6. High quality and competitive price.

7. Design 30 days,manufacturing 60 days

8. Excellent after sale service.

9. Delivery term:EXW,FOB,CIF,DDU,DDP

10.shipping:By Ocean/by Air.

While robotic welding can vastly improve productivity over semiautomatic welding, the level of

efficiency of automation depends upon the thoughtful design of the fixturing for maximum

productivity. Robotic welding is economical when properly applied, but it can be terribly

inefficient and cost-prohibitive when simple fixture design considerations are overlooked. Many

productivity gains are realized, or lost, at the design stage and while parts fixturing performs a

role that is simple, good fixture design is critical to the success of a robotic welding system.\

When beginning a new project for robotic arc welding, consider these fixture design objectives:

Choose Your Fixture Material Wisely

Optimize the Welding Circuit

Orient the Fixture to Maximize Deposition Rates

Strive for Accessibility, Repeatability, Simplicity, and Dependability

Consider Alternatives when Fixture Design Costs are Prohibitive

Our intention is usually to satisfy our buyers by offering golden provider, great rate and good quality for Customized Copper Braid Wire 660kVA Cutting and Invterter Welding Machine. We have independent import and export business rights and have established cooperative relationships with many international famous brands. It is our eternal goal to tap demand, integrate resources, continue to innovate, and create the greatest value for customers.

Hot Tags: robotic welding fixture line, arc-welding robot workstation, spot welding robot workstation China, manufacturers, suppliers, made in China, quotation, body in white welding quality control, cmm fixture development plan, Auto Pillar Parts Welding Fixture, precision machining surface treatment, automobile body in white parts inspection fixture, checking fixture for metal panel gluing

-

![Horizontal Machining Fixture of Direction Turning Servo Motor Checking]() Horizontal Machining Fixture of Direction Turning Servo M...view more>

Horizontal Machining Fixture of Direction Turning Servo M...view more> -

![Metal Panel Checking Fixture in Automotive Industry]() Metal Panel Checking Fixture in Automotive Industryview more>

Metal Panel Checking Fixture in Automotive Industryview more> -

![Automotive Ceiling Sunroof Checking Gauge CMM Fixture Tool]() Automotive Ceiling Sunroof Checking Gauge CMM Fixture Toolview more>

Automotive Ceiling Sunroof Checking Gauge CMM Fixture Toolview more> -

![Hotel/Home/Shop Aluminum Trimless 9W/11W/15W COB Ceiling LED]() Hotel/Home/Shop Aluminum Trimless 9W/11W/15W COB Ceiling LEDview more>

Hotel/Home/Shop Aluminum Trimless 9W/11W/15W COB Ceiling LEDview more> -

![Check Fixture for Car Head Lamp/ Light Trim]() Check Fixture for Car Head Lamp/ Light Trimview more>

Check Fixture for Car Head Lamp/ Light Trimview more> -

![Door Trim Assembly Checking Fixture]() Door Trim Assembly Checking Fixtureview more>

Door Trim Assembly Checking Fixtureview more>